Preparation method and application of a polymer building formwork material

A technology of building templates and polymers, which is applied to the preparation of building components on site, construction, and building construction. It can solve the problems of formwork weight gain, short service life, and high cost, and achieve good impact resistance and long service life. , the effect of using more times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

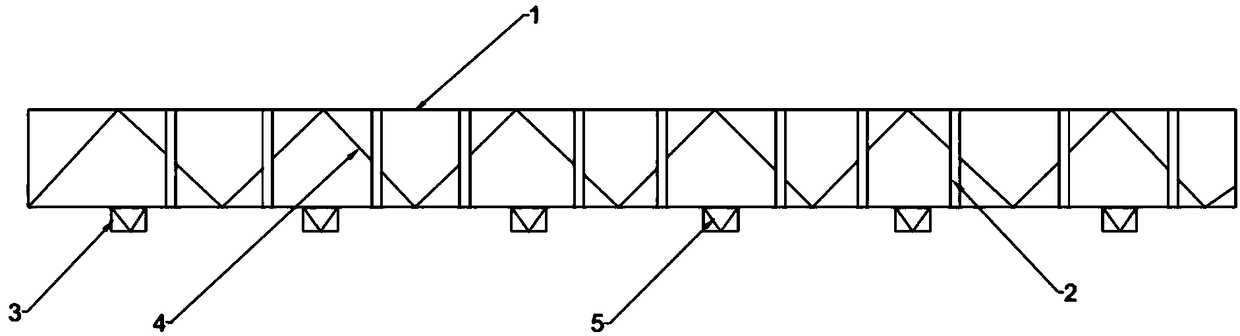

Image

Examples

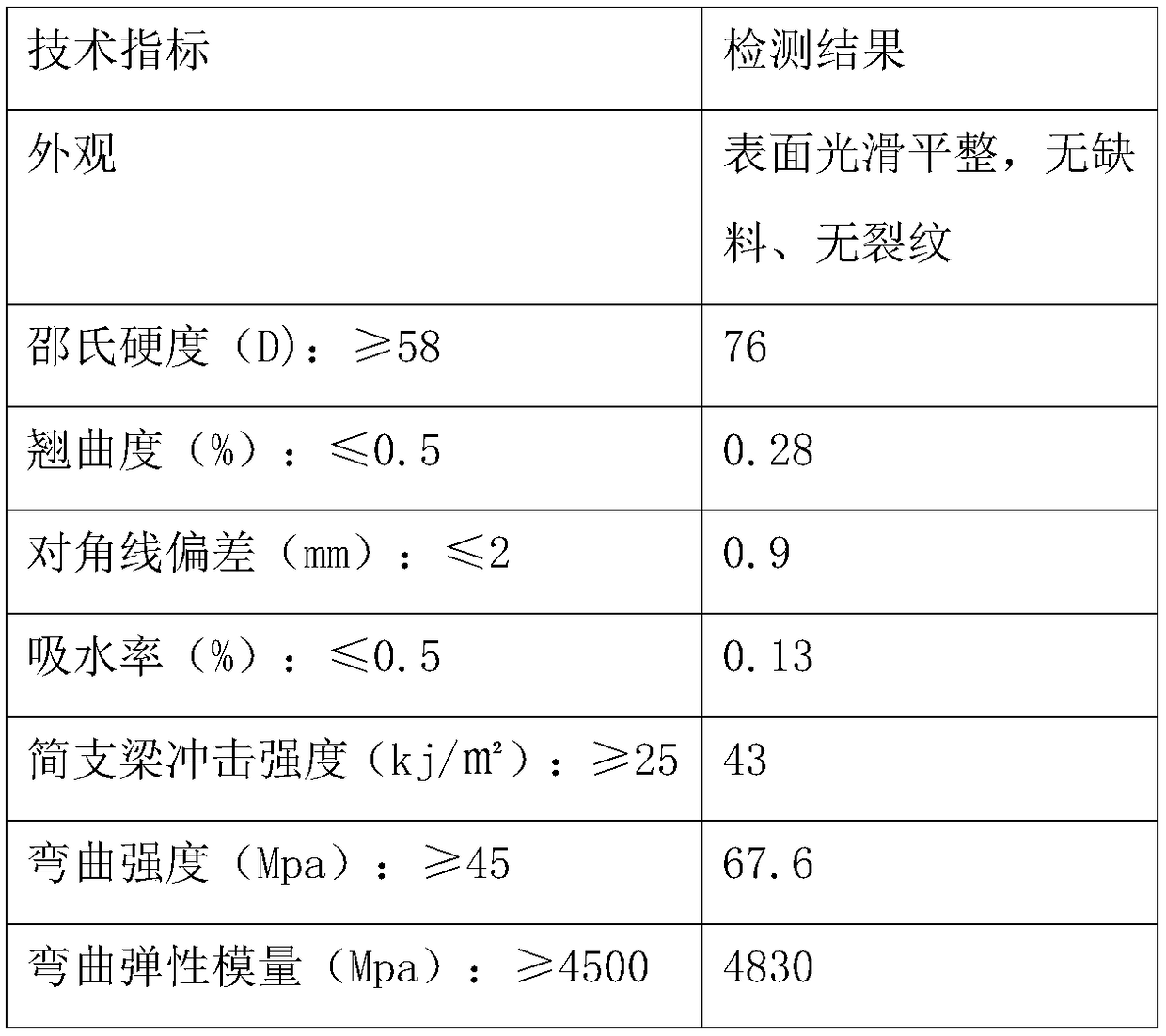

Embodiment 1

[0024] A polymer building formwork material, prepared from the following components according to the mass percentage: isotactic polypropylene PPH-M-O1 50% from Dalian Petrochemical, polyvinyl chloride K-63 28% from the Second Beijing Chemical Plant, Strengthening agent Taiwan Formosa Plastics MBS type 10%, stabilizer lead sulfophosphite compound 3%, foaming agent azodicarbonamide (H2NCON) 3%, antioxidant 10100.5%, antioxidant 1680.5%, Stearic acid 1%, plasticizer Kunlun Petrochemical 56# paraffin oil 4%.

[0025] The preparation method of the polymer building formwork material is:

[0026] (1) Preparation of masterbatch: Weigh each component according to the mass percentage and add it into the twin-screw extruder through a feeder. The temperature is controlled at 180°C, and the masterbatch is made by extruding after continuous mixing for 70s. .

[0027] (2) Preparation of polymer building formwork materials: Put the masterbatch prepared in step (1) into the batching tank thr...

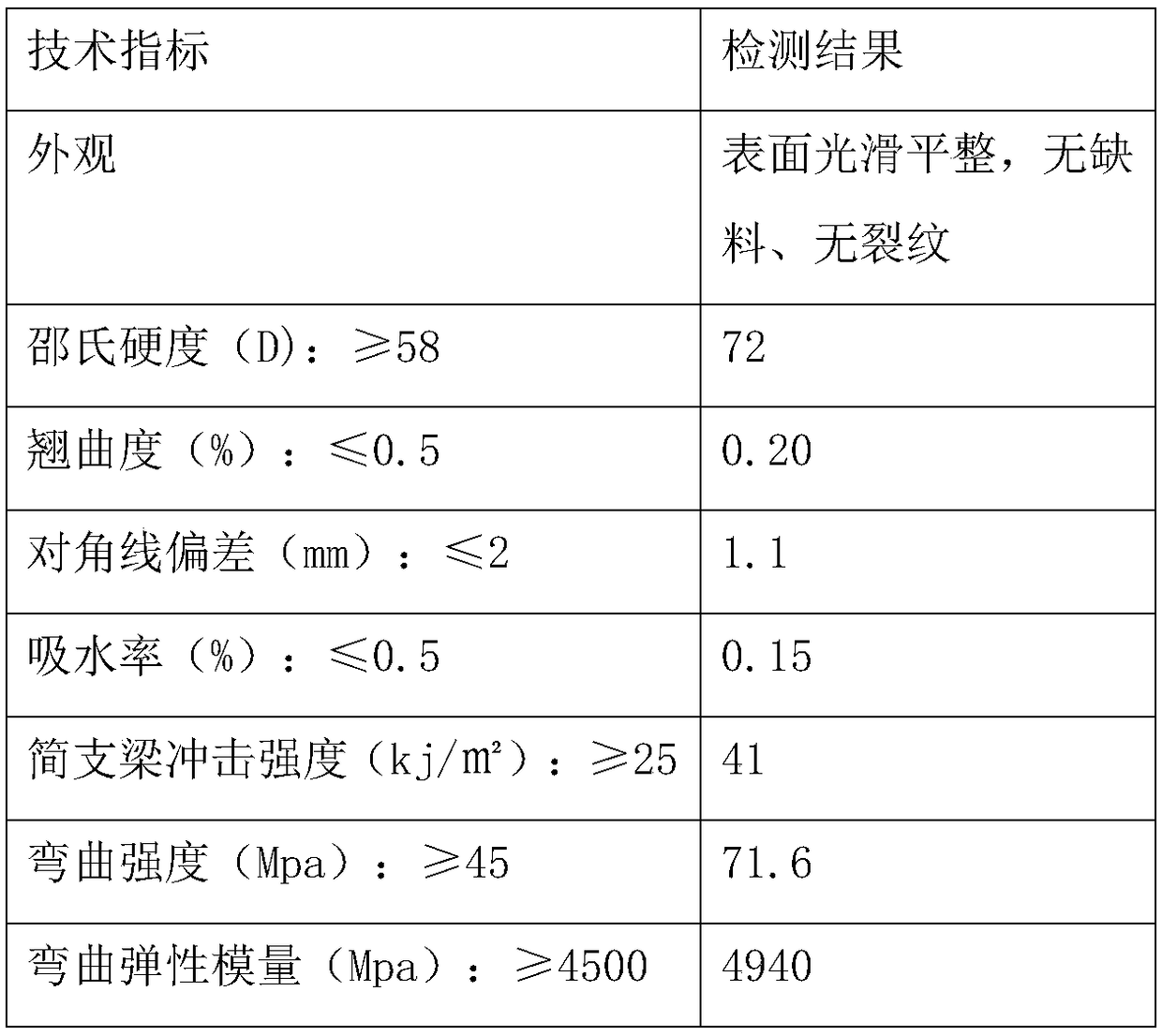

Embodiment 2

[0032] A polymer building template material, prepared from the following components: isotactic polypropylene J40165% produced by Beijing Yanshan Petrochemical, polyvinyl chloride Wuxi Chemical Plant PVC-SP-1 20%, reinforcing agent Taiwan Formosa Plastics MBS type 6 %, Stabilizer Tribasic Lead Sulfate 2%, Foaming Agent Azodicarbonamide (H2NCON) 2%, Antioxidant 1010 0.5%, Antioxidant 1680 0.5%, Stearic Acid 1%, Plasticizer Karamay KN4010 3%.

[0033] The preparation method of the polymer building formwork material is:

[0034] (1) Preparation of masterbatch: Weigh each component according to the mass percentage and add it into the twin-screw extruder through a feeder. The temperature is controlled at 180°C, and the masterbatch is made by extruding after continuous mixing for 70s. .

[0035] (2) Preparation of polymer building formwork materials: Put the masterbatch prepared in step (1) into the batching tank through the feeding device and mix evenly, then add it into the twin-...

Embodiment 3

[0040] A polymer building formwork material, prepared from the following components: isotactic polypropylene J40160% produced by Beijing Yanshan Petrochemical Co., Ltd., polyvinyl chloride H74GP23% produced by Shanghai Chlor-Alkali Chemical Co., Ltd., reinforcing agent polypropylene resin DH-18% , stabilizer lead sulfite 2%, foaming agent azodicarbonamide (H2NCON) 2%, antioxidant 1010 1%, stearic acid 1%, plasticizer Karamay KN4010 3%.

[0041] The preparation method of the polymer building formwork material is:

[0042] (1) Preparation of masterbatch: Weigh each component according to the mass percentage and add it into the twin-screw extruder through a feeder. The temperature is controlled at 180°C, and the masterbatch is made by extruding after continuous mixing for 70s. .

[0043] (2) Preparation of polymer building formwork materials: Put the masterbatch prepared in step (1) into the batching tank through the feeding device and mix evenly, then add it into the twin-screw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com