Method for preparing submicron pore diameter polymer porous membrane

A technology of polymer and porous membrane, which is applied in the field of preparing porous polymer membrane by water drop template method, which can solve the problem of difficulty in preparing porous polymer membrane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0038] Example 1-1: K 6 CoW 12 o 40 Preparation of complex with cationic chain transfer reagent BPMA

[0039] Take 0.5g polymetallic oxygen cluster K 6 CoW 12 o 40 Dissolve in 75mL of anhydrous methanol and 75mL of distilled water mixture, the concentration is 3.3mg / mL; take 0.75g cationic chain transfer reagent and dissolve in 75mL of anhydrous methanol and 75mL of distilled water mixture, the solubility is 5.3mg / mL; The number of moles of cationic chain transfer reagent and K 6 CoW 12 o 40 The molar ratio is about 9:1. Under vigorous stirring, the K 6 CoW 12 o 40 The solution of the cationic chain transfer reagent was added dropwise to the solution of the cationic chain transfer reagent. After the dropwise addition was completed, the stirring was continued for 2 h, and the methanol was used for centrifugal washing 5 times to obtain pure K 6 CoW 12 o 40 Complex. The product mass was 0.62 g.

Embodiment 1-2

[0040] Example 1-2: H 4 SiW 12 o 40 Preparation of complexes with cationic chain transfer reagents

[0041] Take 0.5g polymetallic oxygen cluster H 4 SiW 12 o 40 Dissolve in 25mL of anhydrous methanol and 25mL of distilled water mixture, the concentration is 10mg / mL; take 0.45g of cationic chain transfer reagent BPMA dissolved in 25mL of anhydrous methanol and 25mL of distilled water mixture, the concentration is 9mg / mL; The number of moles of transfer reagent and H 4 SiW 12 o 40 The molar ratio is about 5:1; under the condition of vigorous stirring, the H 4 SiW 12 o 40 The solution was added dropwise into the surfactant solution, and after the dropwise addition was completed, the stirring was continued for 0.5 h, and the methanol was centrifugally washed for 3 times to obtain pure H 4 SiW 12 o 40 Complex, the product mass is 0.66g.

Embodiment 1-3

[0042] Examples 1-3: H 3 PW 12 o 40 Preparation of complexes with cationic chain transfer reagents

[0043] Take 0.5g polymetallic oxygen cluster H 3 PW 12 o 40 Dissolve in 25mL of anhydrous methanol and 25mL of distilled water mixture, the concentration is 10mg / mL; take 0.35g of cationic chain transfer reagent and dissolve BPMA in 25mL of anhydrous methanol and 25mL of distilled water, the concentration is 7mg / mL; The number of moles of transfer reagent and H 3 PW 12 o 40 The molar ratio is about 4:1; under the condition of vigorous stirring, the H 3 PW 12 o 40 Add the solution dropwise into the surfactant solution, continue to stir for 0.5h after the dropwise addition is completed, and use methanol to wash 3 times by centrifugation to obtain pure H 3 PW 12 o 40 Complex, the product mass is 0.59g.

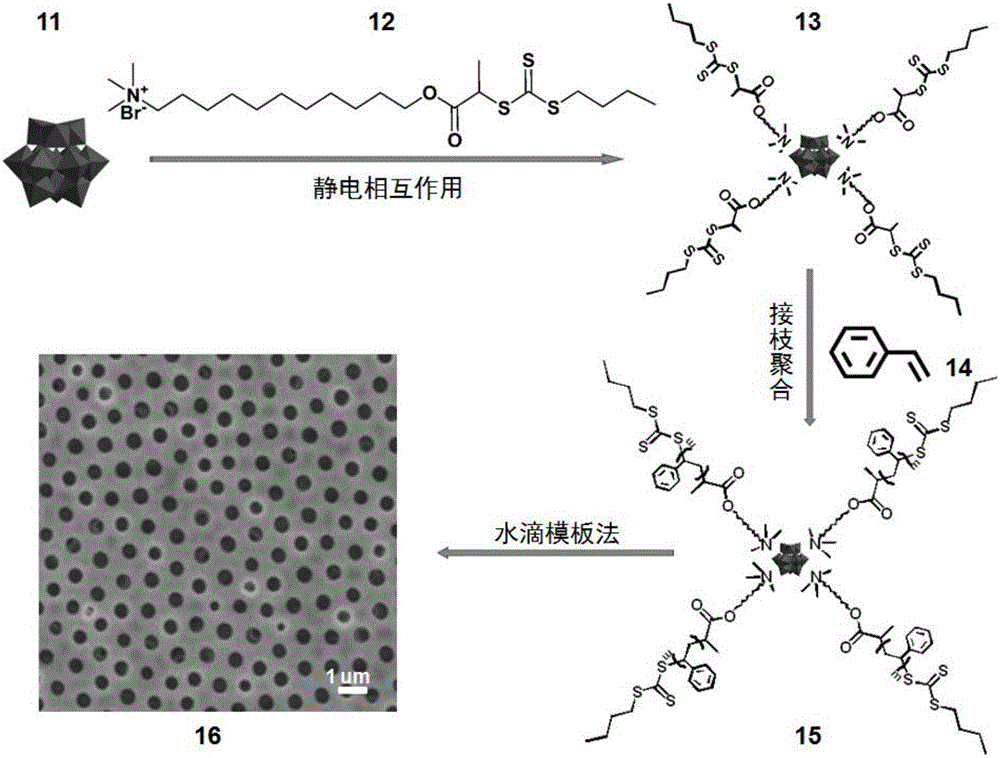

[0044] 2. Preparation of star polymer

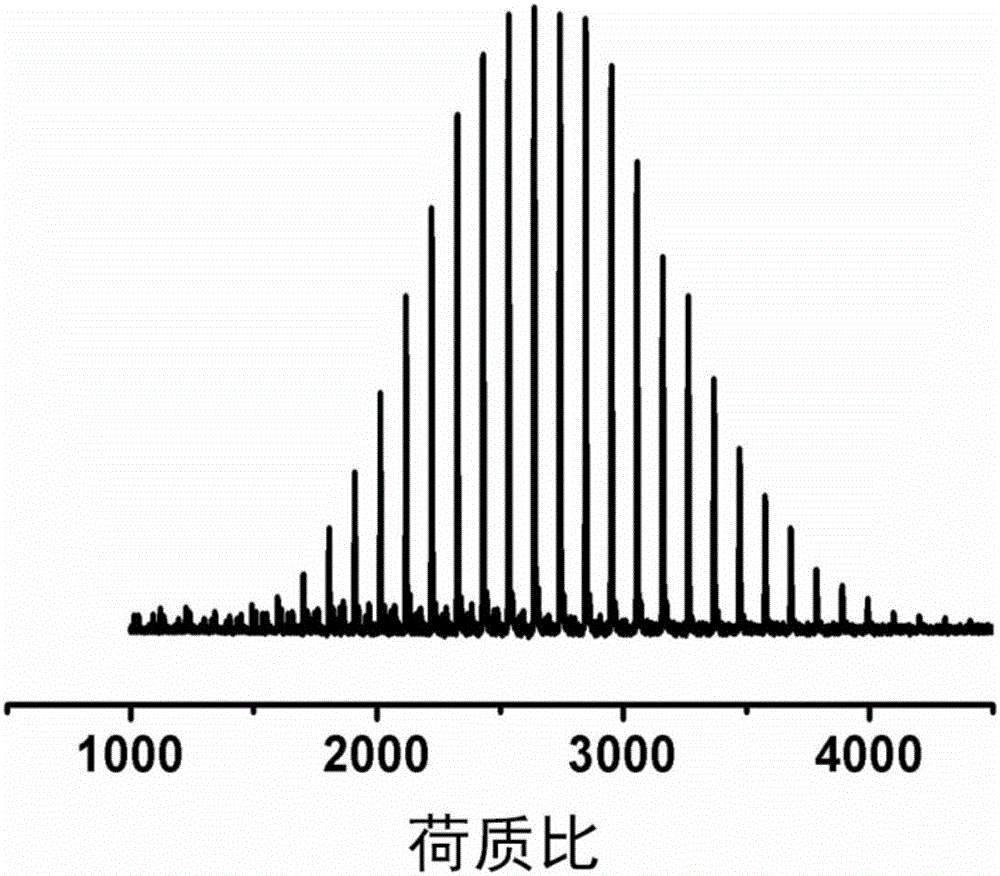

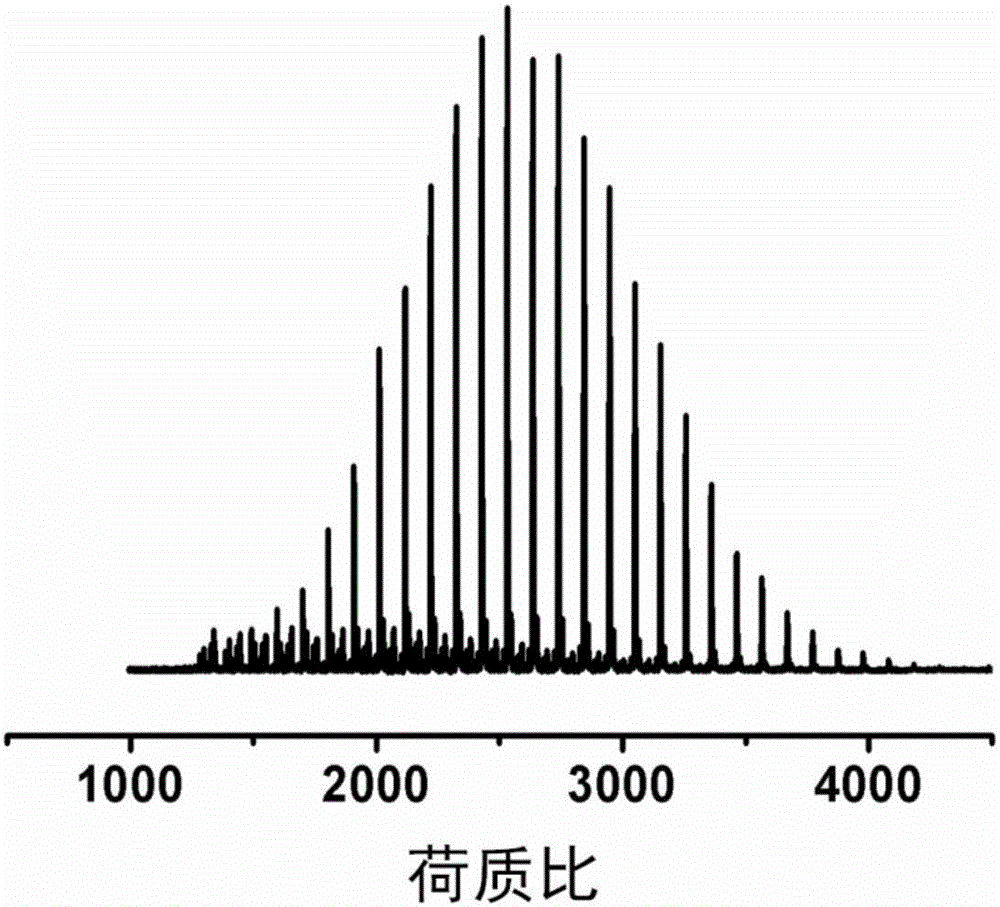

[0045] Principle: The trithiocarbonate group on the periphery of the polymetallic oxygen cluster complex can be used as a ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com