A kind of nitrogen fertilizer slow-release plant growth gelling material and preparation method thereof

A slow-release, nitrogen fertilizer technology, applied in the field of nitrogen fertilizer slow-release plant gelling materials and preparation thereof, can solve problems such as premature death of plants, achieve good slow-release performance of nitrogen fertilizer, improve the slow-release ability of nitrogen fertilizer, and improve the slow-release ability of nitrogen fertilizer. release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

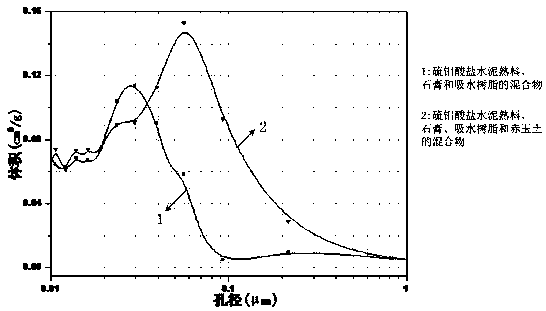

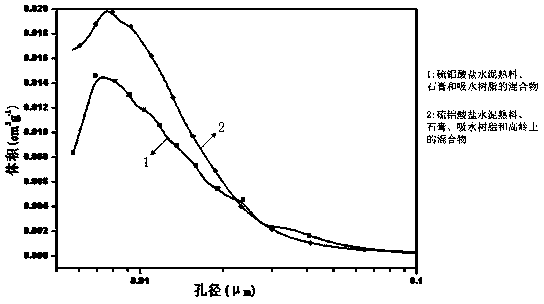

Image

Examples

Embodiment 1

[0032] This embodiment provides a nitrogen fertilizer slow-release plant growth gelling material, including the following components in parts by weight:

[0033] 45 parts of sulfoaluminate cement clinker, 6 parts of natural gypsum, 25 parts of natural red jade soil, 13 parts of washed kaolin, 3 parts of water-absorbing resin, and 8 parts of nitrogen fertilizer; among them,

[0034] The sulphoaluminate cement clinker contains 55% of anhydrous calcium sulphoaluminate, 30% of dicalcium silicate, and 15% of iron phase. The fineness of the sulphoaluminate cement clinker is ground through a 200 mesh sieve, 1% sieved; SO in natural gypsum 3 The content is 40%, and the fineness is ground through a 200-mesh sieve, and the remaining 1.5% is sieved; the fineness of natural red jade soil is ground through a 200-mesh sieve, and the remaining 5% is sieved. 2 The content is 50%, Fe 2 o 3 The content is 15%, Al 2 o 3 The content of MgO is 15%, and the content of MgO is 20%; the fineness ...

Embodiment 2

[0037] This embodiment provides a nitrogen fertilizer slow-release plant growth gelling material, including the following components in parts by weight:

[0038] 60 parts of sulfoaluminate cement clinker, 9 parts of lemon gypsum, 15 parts of natural red jade soil, 10 parts of washed kaolin, 2 parts of water-absorbing resin, 4 parts of nitrogen fertilizer; among them,

[0039] Sulphoaluminate cement clinker contains 65% of anhydrous calcium sulphoaluminate, 20% of dicalcium silicate, and 15% of iron phase. 2%; SO in lemon gypsum 3 The content is 38%, and the fineness is ground through a 200-mesh sieve, and the remaining 1% is sieved; the fineness of natural red jade soil is ground through a 200-mesh sieve, and the remaining 7% is sieved, and the SiO in natural red jade soil 2 The content is 60%, Fe 2 o 3 The content is 10%, Al 2 o 3 The content of MgO is 10%, and the content of MgO is 20%; the fineness of washed kaolin is ground through a 200 mesh sieve, and the remaining ...

Embodiment 3

[0042] This embodiment provides a nitrogen fertilizer slow-release plant growth gelling material, including the following components in parts by weight:

[0043] 70 parts of sulfoaluminate cement clinker, 10 parts of phosphogypsum, 10 parts of natural red jade soil, 5 parts of washed kaolin, 2 parts of water-absorbing resin, 3 parts of nitrogen fertilizer, of which,

[0044] The sulphoaluminate cement clinker contains 65% of anhydrous calcium sulphoaluminate, 30% of dicalcium silicate, and 5% of iron phase, and the fineness of the sulphoaluminate cement clinker is ground to 200 mesh Sieve, remaining 5%; SO in phosphogypsum 3 The content is 37%, and the fineness is ground through a 200 mesh sieve, and the remaining 2.5% is sieved; the fineness of the natural red jade soil is ground through a 200 mesh sieve, and the remaining 10% is sieved, and the SiO in the natural red jade soil 2 The content is 55%, Fe 2 o 3 The content of Al is 14%. 2 o 3 The content of MgO is 16%, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com