Composite material fireproof insulation board and preparation method thereof

A technology for fire-proof thermal insulation board and composite material, applied in the field of thermal insulation materials, can solve the problems of high thermal conductivity, poor thermal insulation effect, and the inability of organic thermal insulation materials to achieve small thermal conductivity, good thermal insulation performance, and meet building energy-saving requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

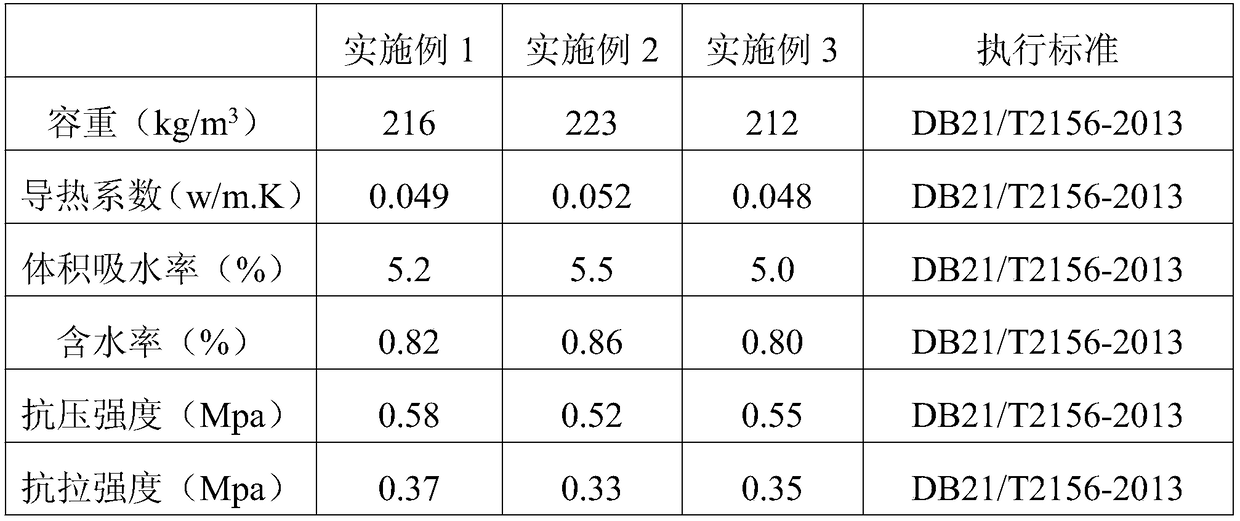

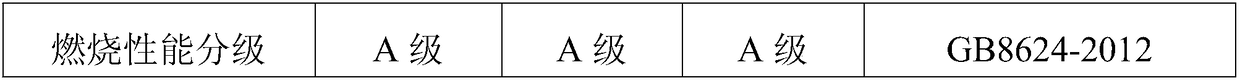

Examples

Embodiment 1

[0022] A composite material fireproof insulation board, made of the following raw materials in parts by weight: 75 parts of expanded perlite, 27 parts of thermoplastic phenolic resin, 17 parts of hexamethylenetetramine, and 12 parts of electrospun carbon nanotube composite micro-nano fiber , 10 parts of carbonized electrospun carbon nanotube composite micro-nano fiber, 8 parts of aluminum hydroxide, and 5 parts of medical stone powder.

[0023] The preparation method of the composite material fire-proof insulation board: prepare materials according to the above-mentioned raw material ratio, dry mix the raw materials evenly, put them into metal molds, close all the molds, put them in a drying room at 80°C to heat, and keep them warm for 45 minutes. After being taken out of the drying room, it is naturally cooled to below 40°C and released from the mold to obtain the finished product.

Embodiment 2

[0025] A composite material fireproof insulation board, made of the following raw materials in parts by weight: 70 parts of expanded perlite, 25 parts of thermoplastic phenolic resin, 15 parts of hexamethylenetetramine, and 8 parts of electrospun carbon nanotube composite micro-nano fiber , 8 parts of carbonized electrospun carbon nanotube composite micro-nano fiber, 6 parts of aluminum hydroxide, and 4 parts of medical stone powder.

[0026] The preparation method of the composite material fireproof insulation board is the same as that of Example 1.

Embodiment 3

[0028] A composite material fireproof insulation board, made of the following raw materials in parts by weight: 80 parts of expanded perlite, 30 parts of thermoplastic phenolic resin, 19 parts of curing agent, 14 parts of electrospun carbon nanotube composite micro-nano fiber, carbonized electrospun 14 parts of carbon nanotube composite micro-nano fiber, 12 parts of aluminum hydroxide, 7 parts of medical stone powder.

[0029] The preparation method of the composite material fireproof insulation board is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com