Method for preparing mesoporous silica gel

A silica gel and cellulose technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of mass production not widely used, high cost, cumbersome process, etc., and achieve a simple and reliable pore size control method and reduce raw materials. Cost, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

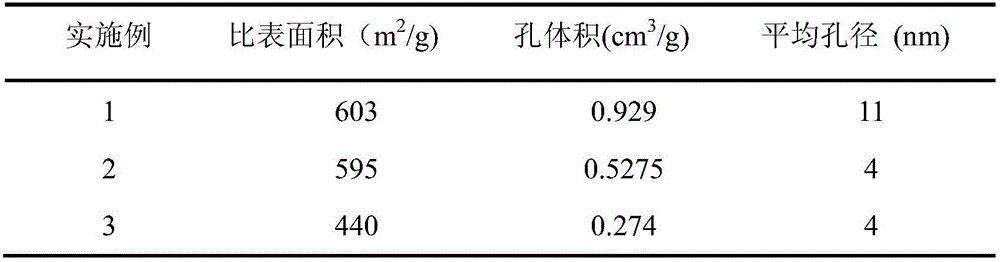

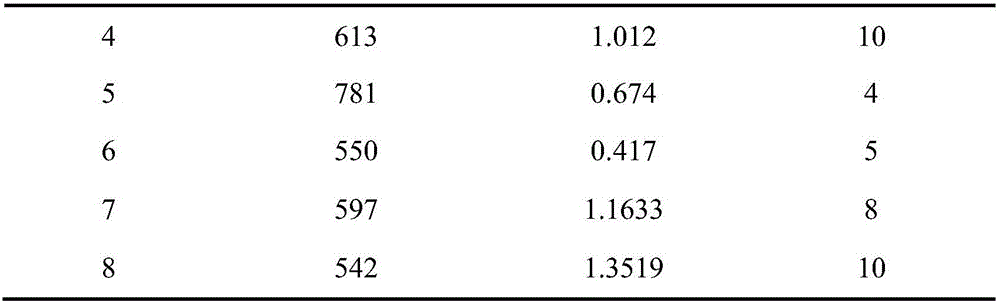

Examples

Embodiment 1

[0023] (1) adding the absorbent cotton to the sulfuric acid solution with a mass concentration of 60%, stirring and mixing evenly, the amount of the absorbent cotton is 30% of the total mass of the absorbent cotton and the sulfuric acid solution;

[0024] (2) Mix the sodium silicate solution with a mass concentration of silicon dioxide of 10% and the material obtained in step (1) evenly so that the pH of the material reaches 1, and stir for 1 h;

[0025] (3) The material obtained in step (2) is subjected to aging gel, the aging gel temperature is 80°C, and the aging gel time is 12h;

[0026] (4) Wash the material obtained in step (3) to neutrality with water to remove salt and salt soluble ions therein, filter and then dry and activate roasting under air atmosphere to obtain the mesoporous silica gel, activated The firing temperature is 500°C, the time is 4h, and the atmosphere is air.

Embodiment 2

[0028] (1) adding the absorbent cotton to the hydrochloric acid solution with a mass concentration of 20%, stirring and mixing evenly, the amount of the absorbent cotton is 25% of the total mass of the absorbent cotton and the hydrochloric acid solution;

[0029] (2) Mix the sodium silicate solution with a mass concentration of silicon dioxide of 25% and the material obtained in step (1) evenly so that the pH of the material reaches 1, and stir for 1 h;

[0030] (3) The material obtained in step (2) is subjected to aging gel, the aging gel temperature is 60°C, and the aging gel time is 1d;

[0031] (4) Wash the material obtained in step (3) to neutrality with water to remove salt and salt soluble ions therein, filter and then dry and activate roasting under air atmosphere to obtain the mesoporous silica gel, activated The firing temperature is 600°C, the time is 6h, and the atmosphere is air.

Embodiment 3

[0033] (1) adding microcrystalline cellulose to a sulfuric acid solution with a mass concentration of 50%, stirring and mixing evenly, the amount of microcrystalline cellulose is 12% of the total mass of microcrystalline cellulose and sulfuric acid solution;

[0034] (2) Mix the sodium silicate solution with a mass concentration of silicon dioxide of 10% and the material obtained in step (1) evenly so that the pH of the material reaches 1, and stir for 1 h;

[0035] (3) The material obtained in step (2) is subjected to aging gel, the aging gel temperature is 25°C, and the aging gel time is 1d;

[0036] (4) Wash the material obtained in step (3) to neutrality with water to remove salt and salt soluble ions therein, filter and then dry and activate roasting under air atmosphere to obtain the mesoporous silica gel, activated The firing temperature is 500°C, the time is 6h, and the atmosphere is air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com