Submarine Pipeline Carrier

A submarine pipeline, streamlined technology, applied in the direction of transportation and packaging, pipeline laying and maintenance, ships, etc., can solve the problems of umbilical cable sling winding, low installation accuracy, increased operating costs, etc., to expand the carrying space, carry Powerful, Accurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

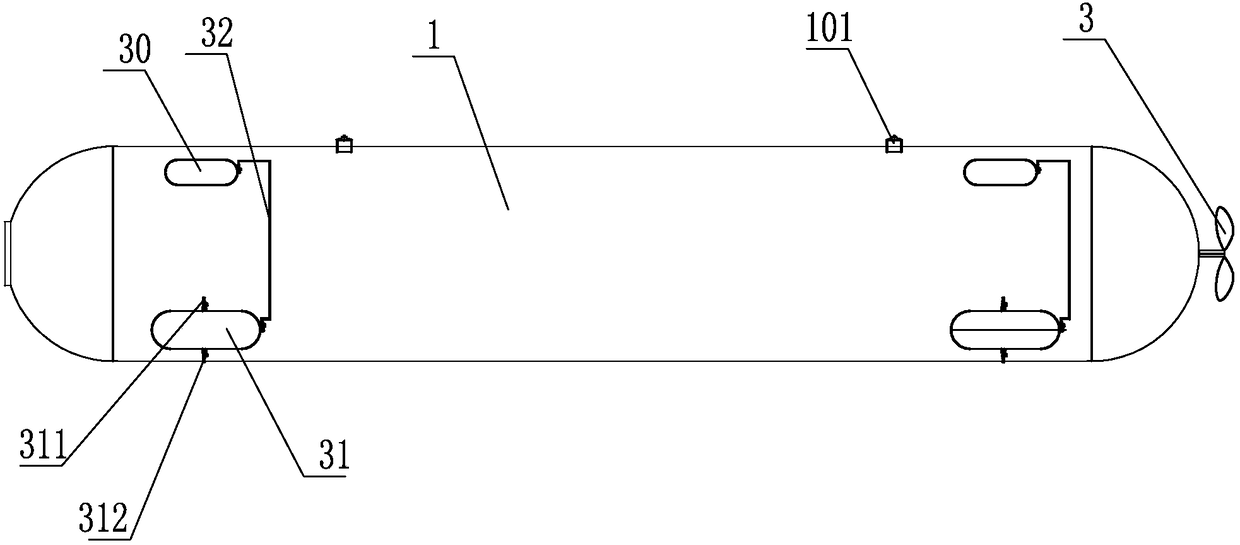

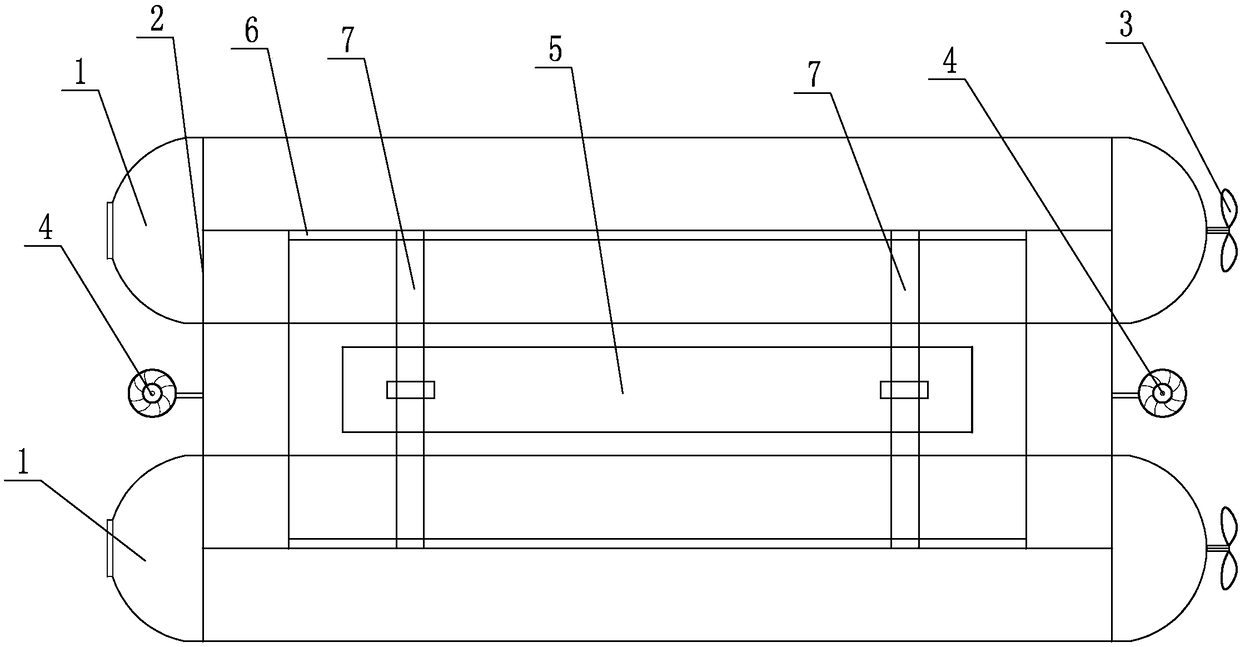

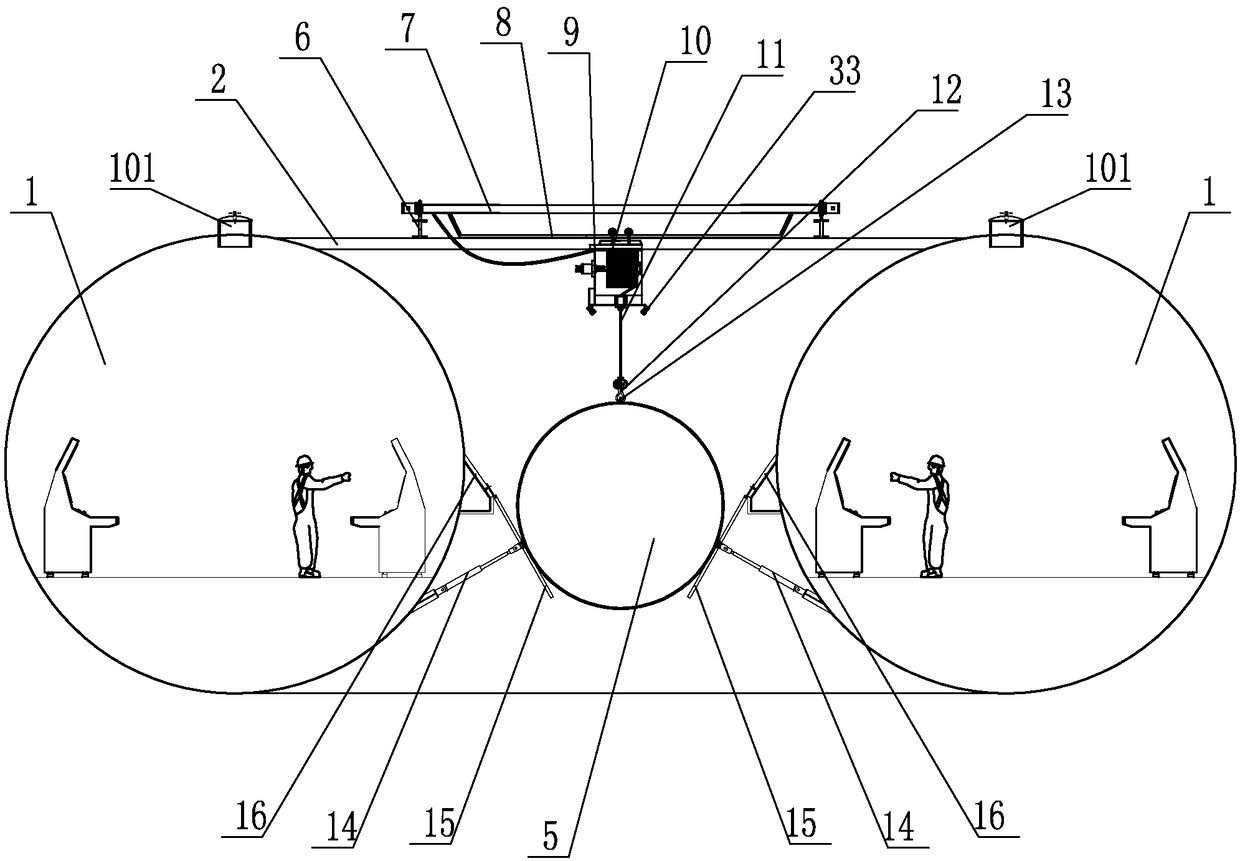

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0031] See figure 1 , figure 2 , image 3 , the present invention includes a submersible carrier composed of two symmetrical streamlined monomers 1, the two streamlined monomers 1 are connected by a connecting frame 2; the tail parts of the two streamlined monomers 1 are respectively installed A vertical propeller 3, a vertical propeller 4 is installed on the connection frame 2, and the vertical propeller 4 is located between two streamlined monomers 1 in the transverse direction, and preferably between two streamlined monomers 1 Vertical propellers 4 are installed at both ends of the longitudinal front and back, and the longitudinal propellers 3 are used to change the direction and position of the transport boat described in the present invention when it navigates underwater. The vertical propellers 4 are used in the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com