Control circuit of dot matrix printer

A dot matrix printer and control circuit technology, applied in printing devices, printing, etc., can solve the problems of high cost, large capacity and high cost, etc., achieve the effects of reducing performance requirements, ensuring effective control, and reducing the amount of software changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Please refer to Figure 2 to Figure 5 , Embodiment 1 of the present invention is:

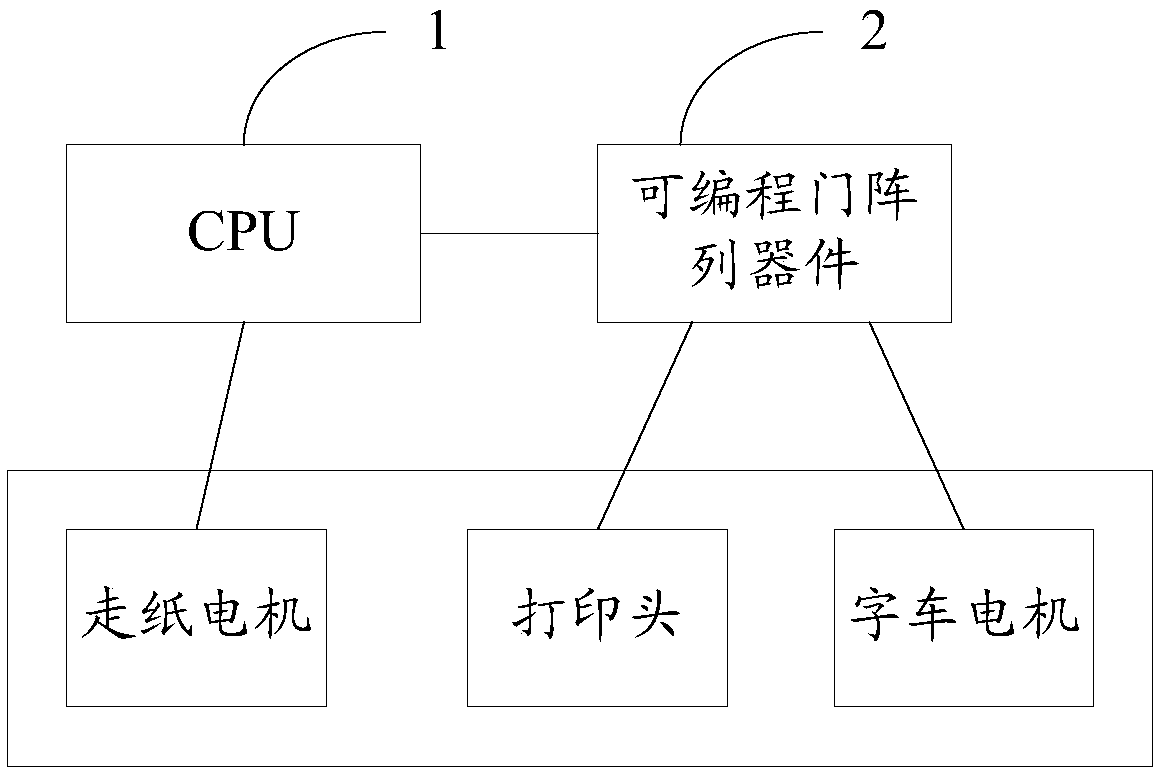

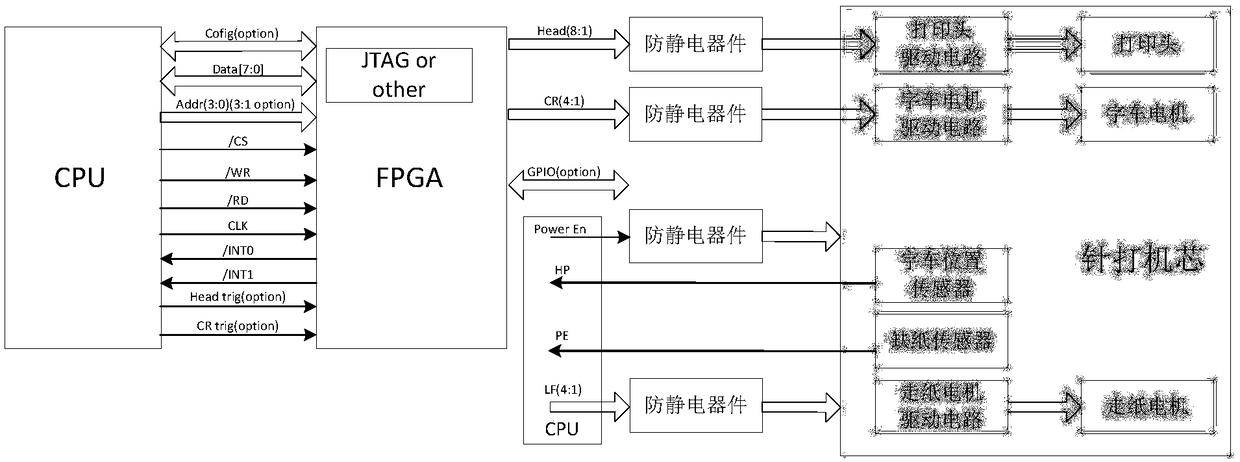

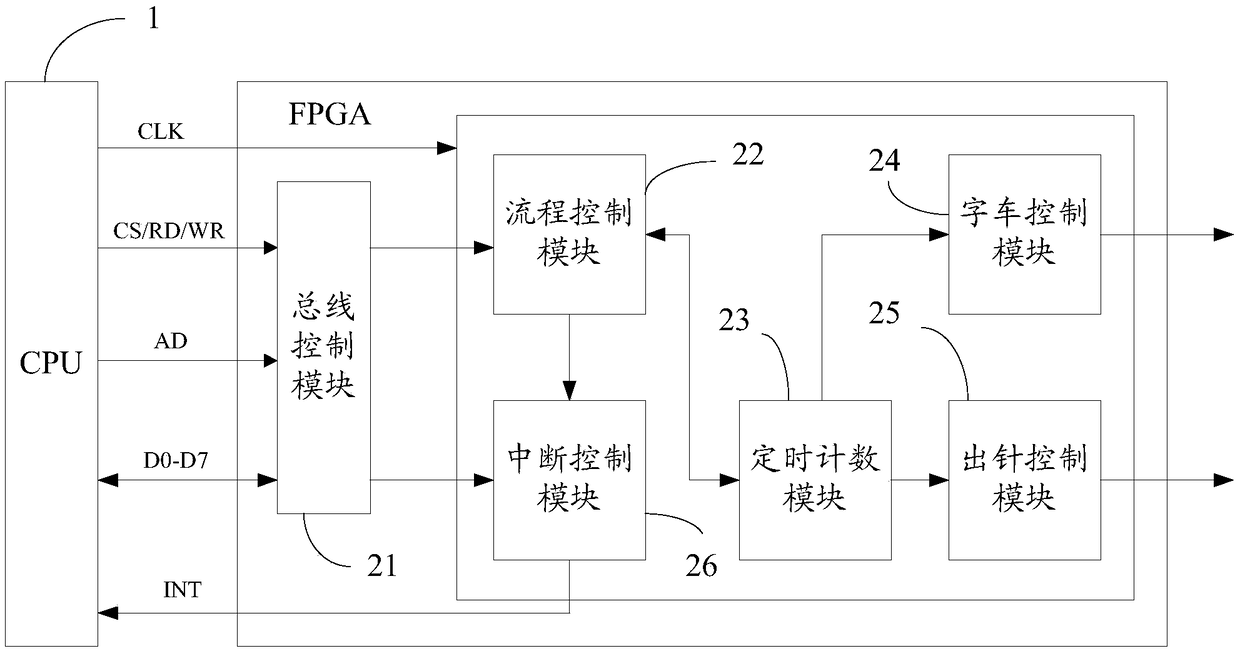

[0049] A control circuit of a dot matrix printer, externally connected to a dot matrix printer, comprising: a CPU needle and an FPGA, the CPU is connected to a paper feed motor of the dot matrix printer, and the FPGA is respectively connected to a print head and a character carriage motor of the dot matrix printer; specifically , the CPU is connected to the dot-type printer’s dot-printing movement through the paper-feeding control line; the FPGA is connected to the dot-striking movement through the character car control line and the needle output control line; at the same time, the CPU and the FPGA are connected through the data communication line and Interrupt line connections, such as figure 2 shown.

[0050] The data transfer between the above CPU and FPGA is realized through an 8-bit data bus, which is composed of one address line, eight data lines, read signal, write signal and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com