A laser welding method for stainless steel thick-walled pressure vessel

A pressure vessel, laser welding technology, applied in laser welding equipment, household containers, welding equipment and other directions, to ensure welding positioning accuracy, ensure strength and air tightness, and solve the effect of arc crater defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The thick-walled pressure vessel in the embodiment of the present invention includes a tank body, a top cover body, a cover plate, a conduit, and a nozzle. One end of the container is connected to the top cover, and the other end is connected to the cover plate; one end of the conduit is connected to the low-pressure gas outlet of the low-pressure buffer container, and the other end is connected to the nozzle; the tank body is connected to the top The cover is made of solid solution strengthened or aging strengthened stainless steel.

[0055] The processing, assembly and welding forming steps of the thick-walled pressure vessel in the embodiment of the present invention specifically include the following:

[0056] (1) Parts processing steps:

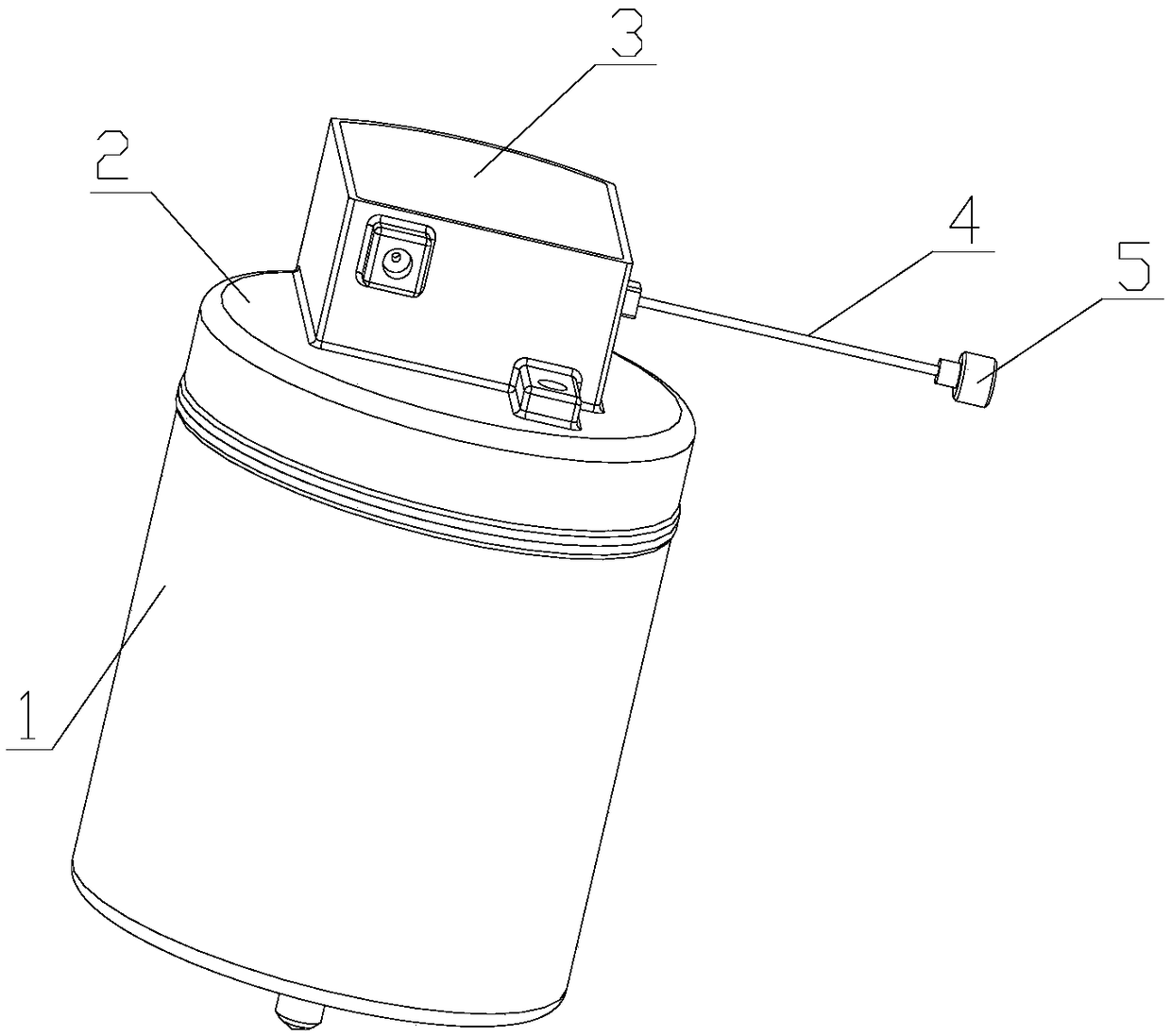

[0057] Such as figure 1 As shown, the ultra-high-strength stainless steel thick-wall pressure vessel is composed of a tank body 1, a top cover body 2, a cover plate 3, a conduit 4, and a nozzle 5.

[0058] 1) Parts processing ...

Embodiment 2

[0087] Embodiment 2 differs from Embodiment 1 in that:

[0088] The continuous welding process parameters of the tank girth seam are:

[0089] a. When the wall thickness of the tank is 5mm~6mm, the laser power is 4.2~4.8KW, the welding speed is 1.2~1.5m / min, the defocus amount is -1mm~2mm, and the shielding gas flow rate is 15~25L / min;

[0090] b. When the tank wall thickness is 6mm~7mm, the laser power is 4.7~5.4KW, the welding speed is 1.0~1.3m / min, the defocus amount is -1.5mm~2.5mm, and the protective gas flow rate is 15~25L / min;

[0091] c. When the wall thickness of the tank is 7mm~8mm, the laser power is 5.2~6.0KW, the welding speed is 0.8~1.2m / min, the defocus amount is -2mm~3mm, and the shielding gas flow rate is 15~25L / min;

[0092] d. When the tank wall thickness is 8mm~9mm, the laser power is 5.8~6.6KW, the welding speed is 0.8~1.2m / min, the defocus amount is -2mm~3mm, and the protective gas flow rate is 15~25L / min;

[0093] e. When the tank wall thickness is 9mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com