A small-diameter seamless magnesium alloy tube cross-rolling process

A technology of seamless magnesium alloy and magnesium alloy, which is applied in metal rolling and other directions, can solve the problems of poor plastic deformation ability of magnesium alloy, easy cracking of seamless magnesium alloy tubes, and shortened processing cycle, so as to achieve excellent comprehensive performance and improve material quality. Utilization, avoiding the effect of anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

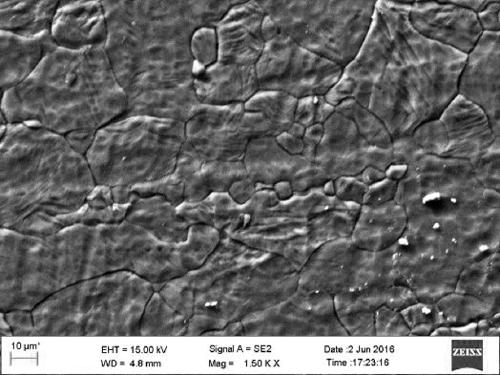

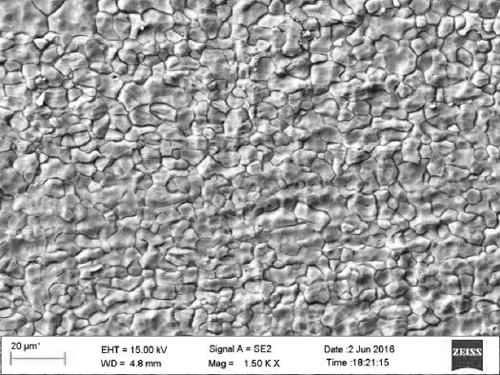

[0046] Such as Figure 1~7 As shown, a small-diameter seamless magnesium alloy tube cross-rolling process is carried out in sequence by the following steps:

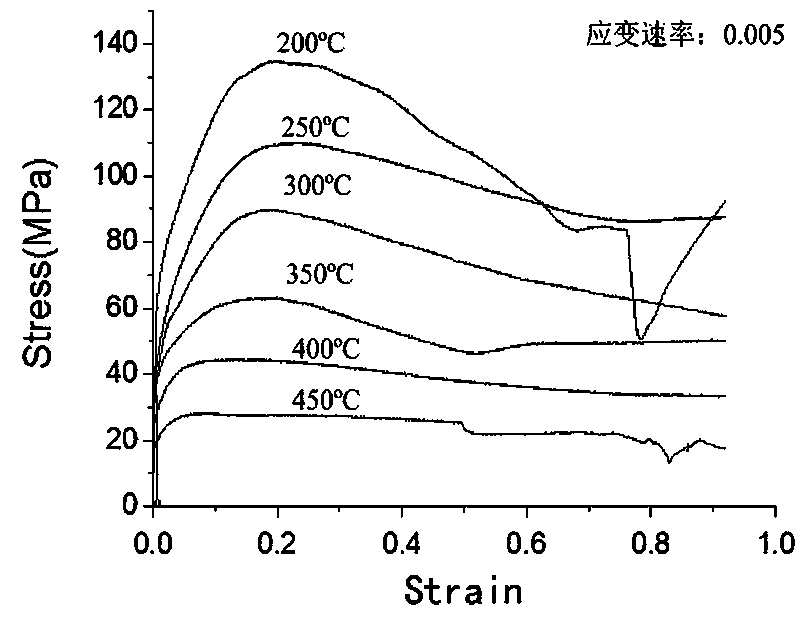

[0047] (1) Establish constitutive equation

[0048] The extruded magnesium alloy was subjected to 0.005s by the Gleeble thermal simulation experiment machine -1 , 0.05 s -1 , 0.5 s -1 、3s -1 Deformation rate, isothermal compression experiment at 200°C, 250°C, 300°C, 350°C, 400°C, 450°C heating temperature conditions, to obtain the true stress-strain curve of the magnesium alloy, and construct the constitutive equation as follows:

[0049] In the formula: R—gas constant, R=8.314 J / (mol K);

[0050] T—absolute temperature, in K;

[0051] — strain rate, in s -1 ;

[0052] —Flow stress, in MPa.

[0053] (2) Establish rolling model

[0054] Use Deform finite element software to simulate the perforation process of seamless magnesium alloy pipes with different temperatures, extensions, and pore throat diameters, i...

Embodiment 2

[0066] A small-diameter seamless magnesium alloy tube cross-rolling process adopts the following steps to carry out in sequence:

[0067] The same as the above-mentioned first embodiment, the constitutive equation and the rolling model are established sequentially, and finally the rolling process parameters in the second embodiment are determined as follows: the rolling temperature is 400°C, the extension of the plug is 20 mm, and the feeding angle is selected to be 7 °, the diameter of the plug is Φ30mm, the diameter of the hole throat is Φ35mm, and the rotational speed of the roll is 170rpm.

[0068] (3) cross rolling piercing

[0069] Ⅰ. The stage to be perforated

[0070] (1) First, punch the centering hole Φ15mm×15mm in the front end of the magnesium alloy bar, and then put the magnesium alloy bar into the heating furnace for preheating. The temperature is the same as that of the core, which is reserved for the cross-rolling and piercing stage;

[0071] (2) Start the s...

Embodiment 3

[0079] A small-diameter seamless magnesium alloy tube cross-rolling process adopts the following steps to carry out in sequence:

[0080] The same as in the first embodiment above, the constitutive equation and the rolling model are established in sequence, and finally the rolling process parameters of the third embodiment are determined as follows: the rolling temperature is 500°C, the extension of the plug is 25mm, and the feeding angle is selected to be 10° , The diameter of the plug is Φ30mm, the diameter of the hole throat is Φ35 mm, and the rotation speed of the roll is 200rpm.

[0081] (3) cross rolling piercing

[0082] Ⅰ. The stage to be perforated

[0083] (1) Firstly, punch a centering hole Φ15mm×15mm in the front end of the magnesium alloy bar, then put the magnesium alloy bar into the heating furnace for preheating, the preheating temperature is 450°C, and the holding time is 2 hours, so that the bar skin The temperature is the same as that of the core, which is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com