Alkylation catalyst and application thereof

A catalyst and alkylation technology, applied in physical/chemical process catalysts, molecular sieve catalysts, organic chemistry and other directions, can solve the problems of only 45% conversion of benzene, not high enough conversion of benzene, and reduced conversion of toluene, etc. Improve activity and selectivity, as well as service life, slow deactivation rate, and good activity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0022] According to a preferred embodiment of the present invention, preferably the mesoporous area of the modified IM-5 molecular sieve is 151-250m 2 / g, the mesopore volume is 0.55-0.75cm 3 / g.

[0023] According to the present invention, preferably the total specific surface area of the modified IM-5 molecular sieve is 350-500m 2 / g, the micropore area is 200-210m 2 / g, the micropore volume is 0.09-0.12cm 3 / g, the total pore volume is 0.65-0.85cm 3 / g.

[0024] As long as the molecular sieve of the present invention meets the foregoing requirements, the purpose of the present invention can be achieved, and there is no special requirement for its preparation method. For the present invention, the preferred molecular sieve is prepared as follows:

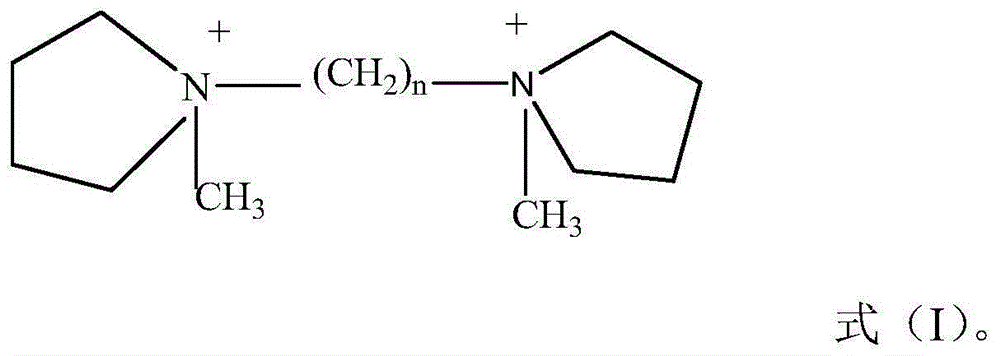

[0025] Under airtight conditions, contact the modifier solution with H-IM-5 molecular sieve, filter, wash, dry, and roast to obtain the modified IM-5 molecular sieve, wherein the modifier solution contains cation, and th...

preparation Embodiment 1

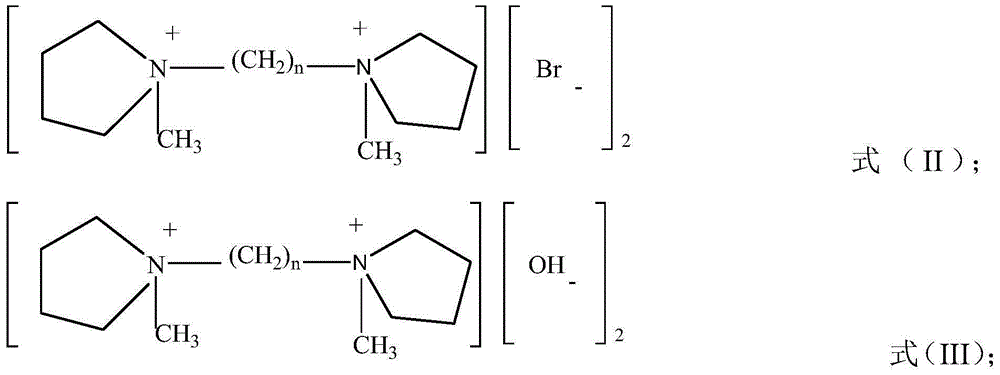

[0068] Prepare IM-5 modified molecular sieve by the method for comparative example 1, difference is that in step (2) with MPPBr 2 (1,5-bis(N-methylpyrrolidine) pentane bromide) and NaOH are formulated into a mixed aqueous solution at a molar ratio of 0.2:1 to replace the NaOH solution. In the mixed solution [OH -1 ] the molar concentration is 0.2mol / L, the reaction time is 2 hours, all the other conditions are the same, and the modified IM-5 molecular sieve Z 2 , the physical and chemical parameters are shown in Table 1.

preparation Embodiment 2

[0070] Prepare the IM-5 modified molecular sieve according to the method of comparative example 1, the difference is, use MPPBr in step (2) 2 (1,5-bis(N-methylpyrrolidine) pentane bromide) and NaOH are formulated into a mixed aqueous solution at a molar ratio of 0.3:1 to replace the NaOH solution, and [OH -1 ] the molar concentration is 0.2mol / L, the reaction time is 2 hours, all the other conditions are the same, and the modified IM-5 molecular sieve Z 3 , the physical and chemical parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore volume | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com