Magnetic fluorinated adsorbent for selective adsorption of PFOS, preparation method and application thereof

A technology of fluorooctane sulfonate and adsorbent, which is applied in the field of magnetic fluorinated adsorbent for selectively adsorbing perfluorooctane sulfonate and its preparation and application, and can solve the problem of poor selectivity, poor adsorption effect, and slow adsorption and other problems, to achieve the effect of no loss in removal rate, easy magnetic separation, and maintenance of magnetic separation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

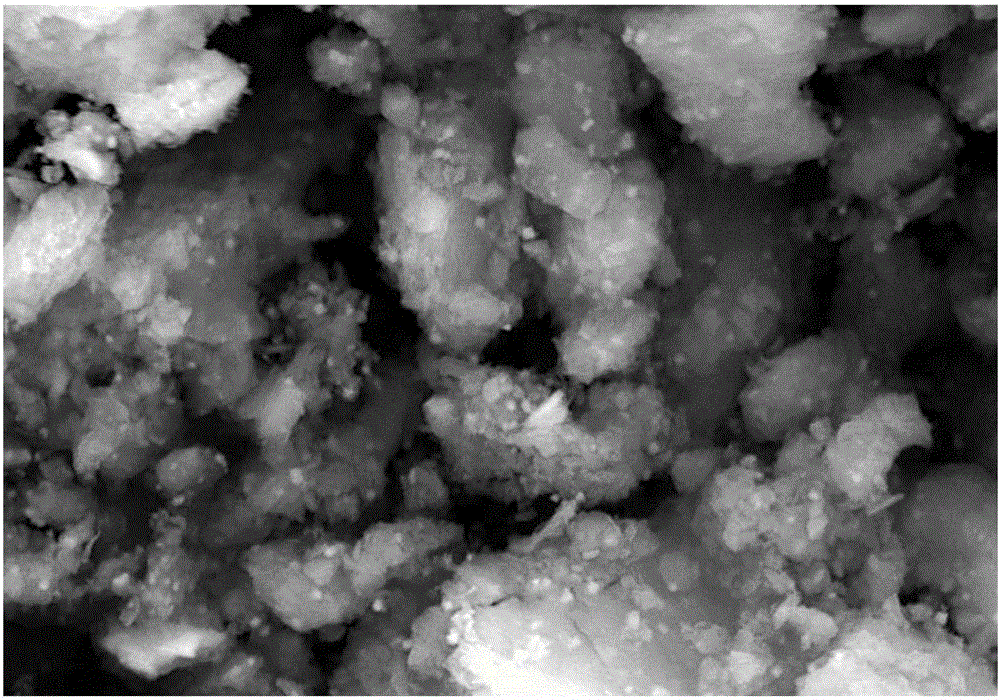

Image

Examples

Embodiment 1

[0051] 1. Preparation of adsorbent

[0052] (1) Add 200g of vermiculite to deionized water at a mass ratio of 1:12 to water, stir for 4 hours, and settle for 10 hours. Purify by siphon method, take the part with a particle size of <2 μm for centrifugation, dry at 110 degrees Celsius, and grind through a 100-mesh sieve.

[0053] (2) Take 5 g of the vermiculite prepared in step (1) and place it in a 0.5 mol / L quaternary ammonium fluoride iodide solution at 85 degrees Celsius, the mass ratio of the vermiculite to the solution is 1:12, and stir for 10 h.

[0054] (3) Wash the fluorinated vermiculite obtained in step (2) repeatedly in 80% methanol until no organic nitrogen is detected in the washing water, and dry the washed fluorinated vermiculite at 65 degrees Celsius.

[0055] (4) Mix the dried and sieved fluorinated vermiculite with nanometer iron ferric oxide, the mass ratio of the two is 20:1, put them in the ball mill tank, and add stainless steel balls, the ball-to-materia...

Embodiment 2

[0069] 1. Preparation of adsorbent

[0070](1) Add 200g of bentonite to deionized water at a mass ratio of 1:10 to water, stir for 3 hours, and settle for 10 hours. Purify by siphon method, take the part with a particle size of <2 μm for centrifugation, dry at 110 degrees Celsius, and grind through a 100-mesh sieve.

[0071] (2) Take 5 g of bentonite prepared in step (1) and place it in 0.4 mol / L quaternary ammonium iodide fluoride solution at 85 degrees Celsius, the mass ratio of bentonite to solution is 1:15, and stir for 12 hours.

[0072] (3) Wash the fluorinated bentonite obtained in step (2) repeatedly in 70% methanol until no organic nitrogen is detected in the washing water, and dry the washed fluorinated bentonite at 70 degrees Celsius.

[0073] (4) Mix the fluorinated bentonite after drying and sieving with nano-ferric iron tetroxide, the mass ratio of the two is 15:1, place in the ball mill tank, and add stainless steel balls, the ball-to-material ratio is 10:1, C...

Embodiment 3

[0084] 1. Preparation of adsorbent

[0085] (1) Add 200g of montmorillonite into deionized water at a mass ratio of 1:12 to water, stir for 5 hours, and settle for 15 hours. Purify by siphon method, take the part with a particle size of <2 μm for centrifugation, dry at 110 degrees Celsius, and grind through a 100-mesh sieve.

[0086] (2) Take 5 g of the montmorillonite prepared in step (1) and place it in a 0.5 mol / L quaternary ammonium iodide fluoride solution at 80 degrees Celsius, the mass ratio of the montmorillonite to the solution is 1:10, and stir for 15 hours.

[0087] (3) Washing the fluoromontmorillonite obtained in step (2) repeatedly in 90% methanol until no organic nitrogen is detected in the washing water, and drying the washed fluoromontmorillonite at 60 degrees Celsius.

[0088] (4) Mix the fluorinated montmorillonite after drying and sieving with nanometer iron ferric oxide, the mass ratio of the two is 19:1, place in the ball mill tank, and add stainless ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com