Processing method of chewy ready-to-eat radix ginseng rubra

A processing method and technology of red ginseng, applied in the confectionary industry, the function of food ingredients, confectionery, etc., can solve the problems of cumbersome processing procedures, low content of rare ginsenosides, and poor taste, and achieve natural color, novel taste, The effect of taste Q bomb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

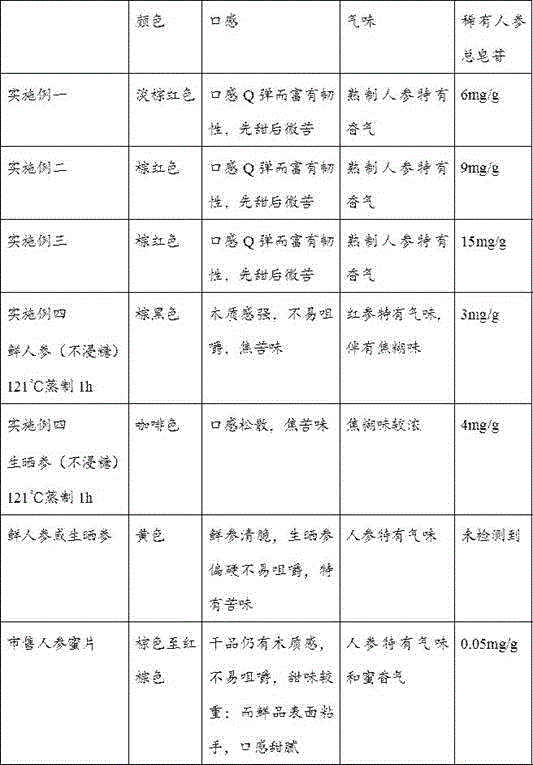

Embodiment 1

[0020] Cut raw sun-dried American ginseng into slices with a thickness of 1.5mm, and spray purified water evenly for multiple times to remoisturize, which is about 0.5 times that of the raw material. The water-absorbing slices were placed in 60% fructose solution, soaked at 60°C for 8 hours, removed, and the excess sugar solution on the surface was filtered off. Then steam at 110°C for 3 hours. After steaming, dry at 45°C in a ventilated dryer until the water content is less than 15%, which is the finished product of Q bomb instant red ginseng slices. The color of the finished product is natural, showing light brownish red, good light transmittance, Q-bomb taste, sweet at first when taking it, and then slowly returning to the unique slightly bitter taste of American ginseng.

[0021] Take the finished ginseng product, extract it with methanol, evaporate the methanol from the extract, then use D101 macroporous adsorption resin to enrich the total ginsenosides, elute with ethano...

Embodiment 2

[0023] Slice fresh ginseng with a thickness of 2mm, put it into 70% fructooligosaccharide solution, soak it at 70°C for 5 hours, remove it, and filter off the excess sugar solution on the surface. Then steam at 121°C for 0.5h. After steaming, dry in a ventilated drier at 50°C until the water content is less than 15%, which is the finished product of Q bomb instant red ginseng slices. The finished product is brownish-red in color, with a springy and tough taste. When ingested, it is sweet at first, and then slowly returns to the unique slightly bitter taste of ginseng.

[0024] Take the finished ginseng product, extract it with methanol, evaporate the methanol from the extract, then use D101 macroporous adsorption resin to enrich the total ginsenosides, elute with ethanol, evaporate the eluate to dryness, and use HPLC to detect the above-mentioned Q-bomb ready-to-eat The total content of rare ginsenosides Rg3, Rh2, Rg2 and Rh1 in red ginseng tablets was detected to be 9mg / g.

Embodiment 3

[0026] Cut raw sun-dried Panax notoginseng into slices, with a thickness of 2.5mm, and spray pure water evenly for several times, which is about 1 times the raw material. Put it into a mixed solution of 70% fructose and xylo-oligosaccharide, soak it at 90°C for 5 hours, remove it, and filter off the excess sugar solution on the surface. Then steam at 121°C for 1 hour. After steaming, dry in a freeze dryer until the water content is less than 5%, which is the finished product of Q bomb instant red ginseng slices. The finished product is brownish-red in color, and it is crispy when chewed in the mouth. After swallowing it and softening, it returns to the Q-elasticity. It is sweet at first, and then slowly returns to the unique slightly bitter taste of Panax notoginseng.

[0027] Take the finished ginseng product, extract it with methanol, evaporate the methanol from the extract, then use D101 macroporous adsorption resin to enrich the total ginsenosides, elute with ethanol, evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com