Real-time simulation method for laser three-dimensional printing process

A 3D printing and real-time simulation technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as long cycle, high cost, and process parameter failure, so as to reduce dependence, increase R&D speed, and reduce The effect of R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

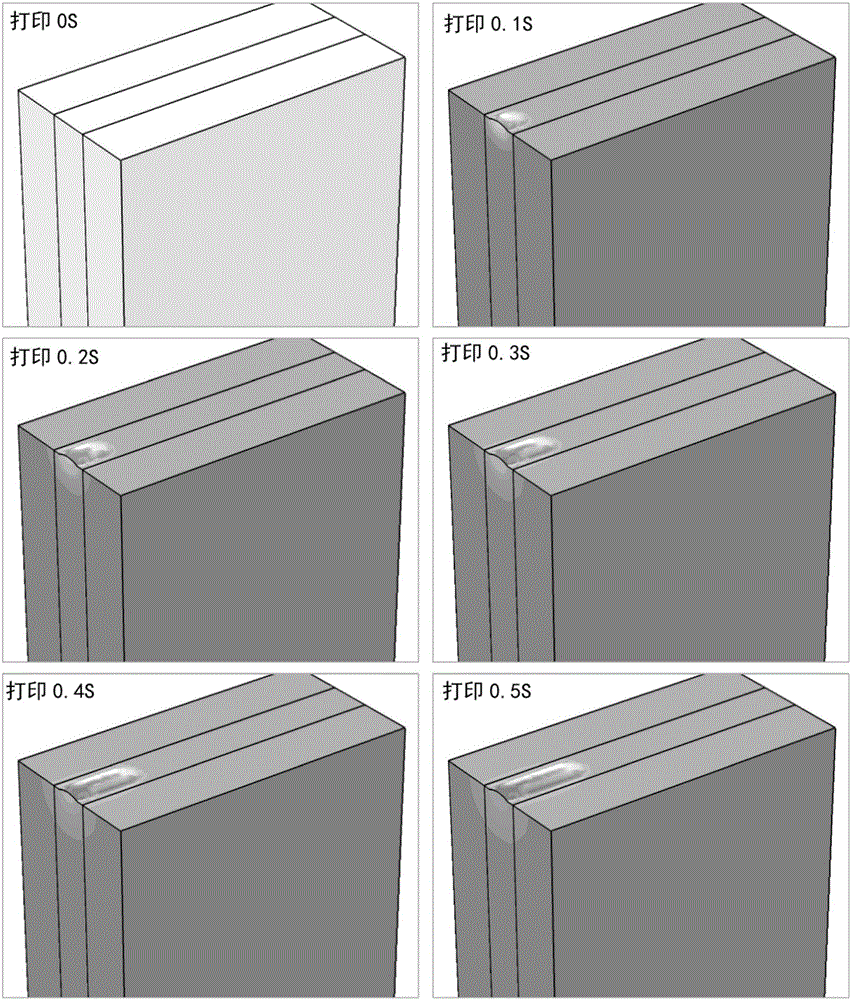

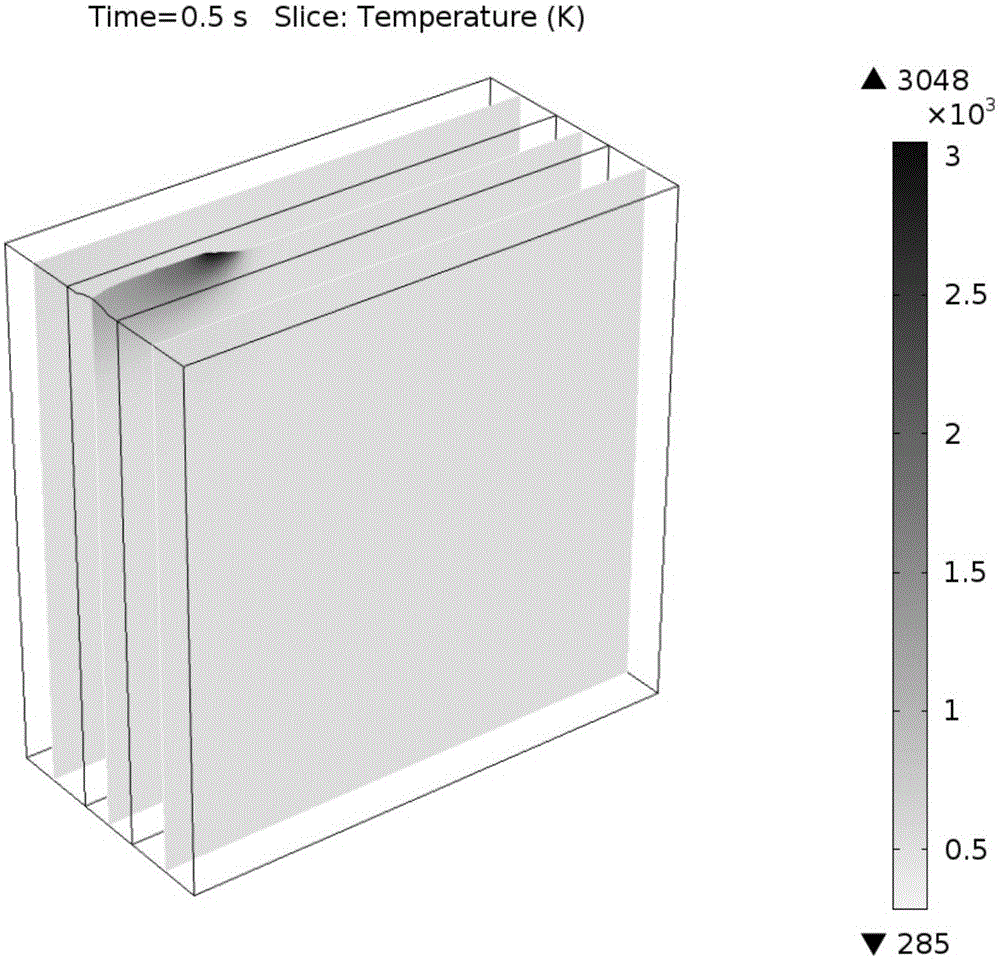

[0086] Taking superalloy DD5 as an example, laser 3D printing with coaxial powder feeding is carried out on a substrate with a length of 2 cm × width of 1 cm × height of 2 cm. The laser power is 1500W, the laser absorption rate is set to 15%, and the spot radius is set to 0.7mm. The powder feeding rate is 10g / min, and the powder is distributed in a circle with a radius of 1.5mm. During the printing process, the laser scanning speed is 600mm / min. Using the calculation method introduced above, the shape and size change map of the substrate during the printing process can be obtained, as shown in figure 1 shown. exist figure 1 The shape and size changes from 0s, 0.1s, 0.2s, 0.3s, 0.4s to 0.5s are shown in . The temperature field distribution can be obtained by taking the profile at 0.5s from the calculation results, such as figure 2 shown. Taking the profile at 0.5s in the calculation results can also get the distribution of the temperature gradient, such as image 3 show...

Embodiment 2

[0088] Taking the superalloy DD5 as an example, laser 3D printing of powder coating is carried out on a substrate with a length of 2cm x width of 1cm x height of 2cm. The laser power is 1500W, the laser absorption rate is set to 15%, and the spot radius is set to 0.7mm. The powder coating thickness is 0.2mm. During the printing process, the laser scanning speed is 1200mm / min. Similarly, the shape and size change map of the substrate during the printing process can be obtained through calculation, such as Figure 4 shown. exist Figure 4 The shape and size changes from 0s, 0.05s, 0.10s, 0.15s, 0.20s to 0.25s are shown in .

Embodiment 3

[0090] Taking superalloy DD5 as an example, laser 3D printing with coaxial powder feeding is carried out on a substrate with a length of 1.5 cm × width of 1 cm × height of 2 cm. The laser power is 1500W, the laser absorption rate is set to 15%, and the spot radius is set to 0.7mm. The powder feeding rate is 10g / min, and the powder is distributed in a circle with a radius of 1.5mm. During the printing process, the laser scanning speed is 600mm / min, and the distance between adjacent passes is 1.05mm. When the shape factor is not added, the calculation result is as follows Figure 5 shown. After adding the shape factor, the calculation result is as follows Figure 6 shown. Figure 5 There are many abrupt sharp corners in , and this phenomenon is well suppressed after adding the shape factor (such as Figure 6 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com