LED heat-radiating fins of surface micro-tooth structures and preparation method of LED heat-radiating fins

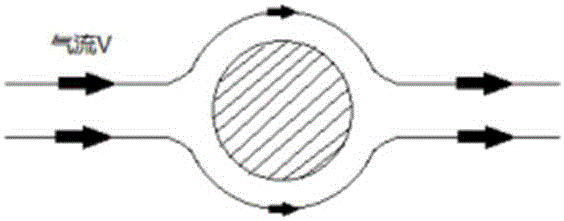

A heat dissipation fin and micro-tooth technology, applied in the field of LED heat dissipation fins with surface micro-tooth structure and its preparation, can solve problems such as insufficient heat dissipation performance, achieve simple and economical manufacturing process, high replication ratio of array structure, and improve convection conversion The effect of heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

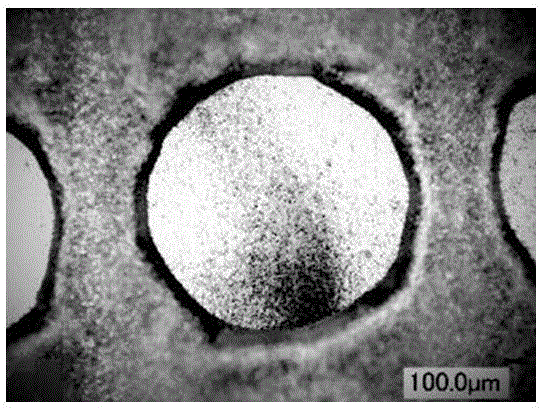

[0040] Preparation of LED cooling fins with an array of frusto-conical micro-tooth structures on the surface

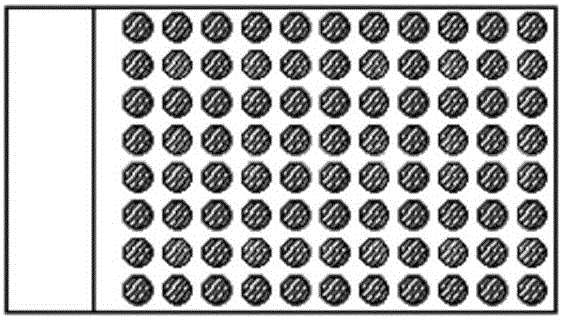

[0041] (1) Preparation of resist template: use AutoCAD software to design array circular graphics, and print black opaque array circular graphics on transparent plate-making film by inkjet printing to make resist template; the obtained array circle The schematic diagram of the resist template with the shape structure is shown in figure 1 shown;

[0042] (2) Surface polishing and degreasing treatment are carried out on the flat fins made of copper, and the photoresist dry film is flattened and bonded on the surface of the fins without air bubbles through a thermoplastic sealing machine; the resist template is aligned and placed On the copper fin with a photoresist dry film on the surface, press the resist template with a 1mm thick transparent carrier film, place it on the bottom of the portable UV curing machine for UV curing, the UV curing power is 1kw, and the main ...

Embodiment 2

[0052] Preparation of LED cooling fins with an array of tetragonal truncated micro-tooth structures on the surface

[0053] (1) Preparation of anti-corrosion template: use AutoCAD software to design array rectangular graphics, and print black opaque array rectangular graphics on transparent plate-making film by inkjet printing to make anti-corrosion templates;

[0054] (2) Surface polishing and degreasing treatment are carried out on the flat fins made of copper, and the photoresist dry film is flattened and bonded on the surface of the fins without air bubbles through a thermoplastic sealing machine; the resist template is aligned and placed On the copper fin with a photoresist dry film on the surface, press the resist template with a 1mm thick transparent carrier film, place it on the bottom of the portable UV curing machine for UV curing, the UV curing power is 1kw, and the main UV peak is 365nm. The distance is 120mm, and the curing time is 12s;

[0055] (3) The photoresi...

Embodiment 3

[0060] Preparation of LED cooling fins with array groove micro-tooth structure on the surface

[0061] (1) Preparation of anti-corrosion template: use AutoCAD software to design array bar graphics, and print black opaque array bar graphics on transparent plate-making films by inkjet printing to make anti-corrosion templates;

[0062] (2) Surface polishing and degreasing treatment are carried out on the fins made of copper, and the photoresist dry film is flattened and bonded on the surface of the fins without air bubbles through a thermoplastic sealing machine; the anti-corrosion template is aligned and placed on the On the copper fin with a photoresist dry film on the surface, press the resist template with a 1mm thick transparent carrier film, place it on the bottom of the portable UV curing machine for UV curing, the UV curing power is 1kw, the main UV peak is 365nm, and the irradiation distance 100mm, curing time is 10s;

[0063] (3) The photoresist dry film special devel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com