Noise reduction water nozzle

A faucet and water outlet pipe technology, which is applied to valve details, pipes/pipe joints/pipe fittings, engine components, etc., can solve the problems of loud water outlet, high impact force, and loud noise, etc., and achieve water outlet pressure reduction, keep quiet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

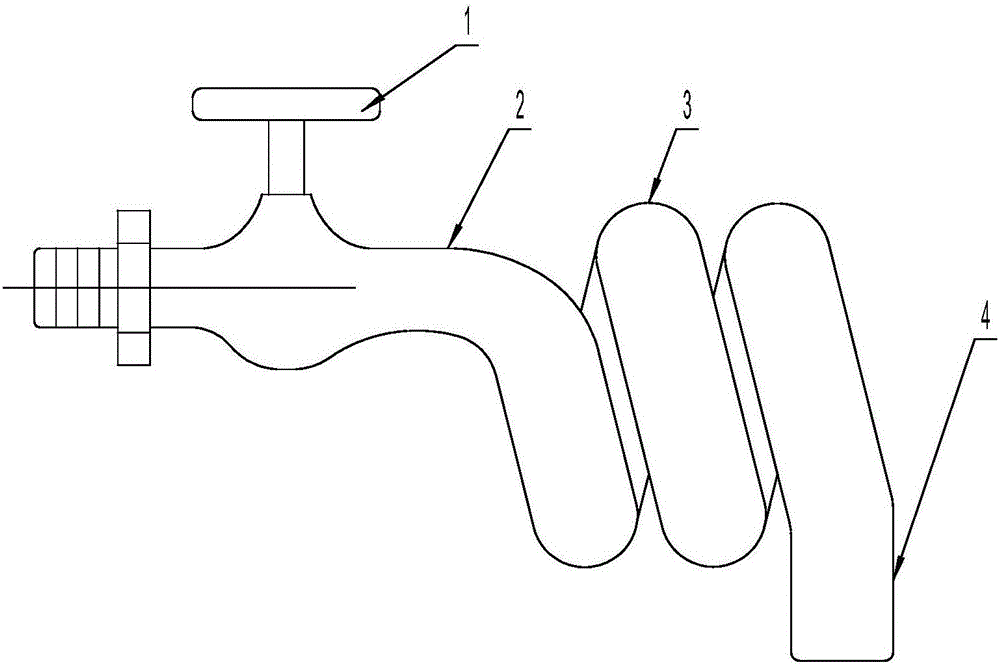

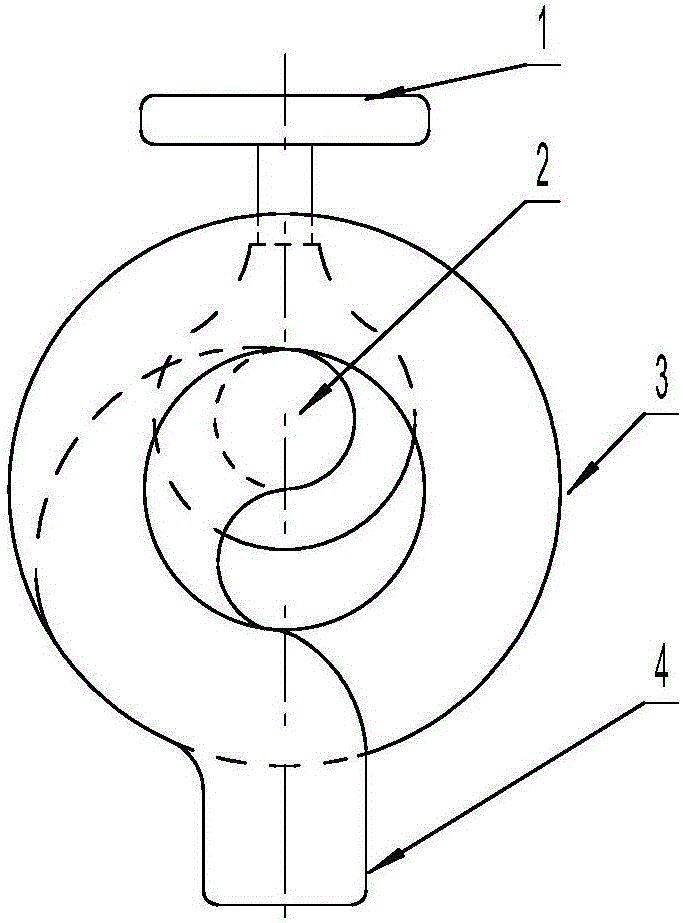

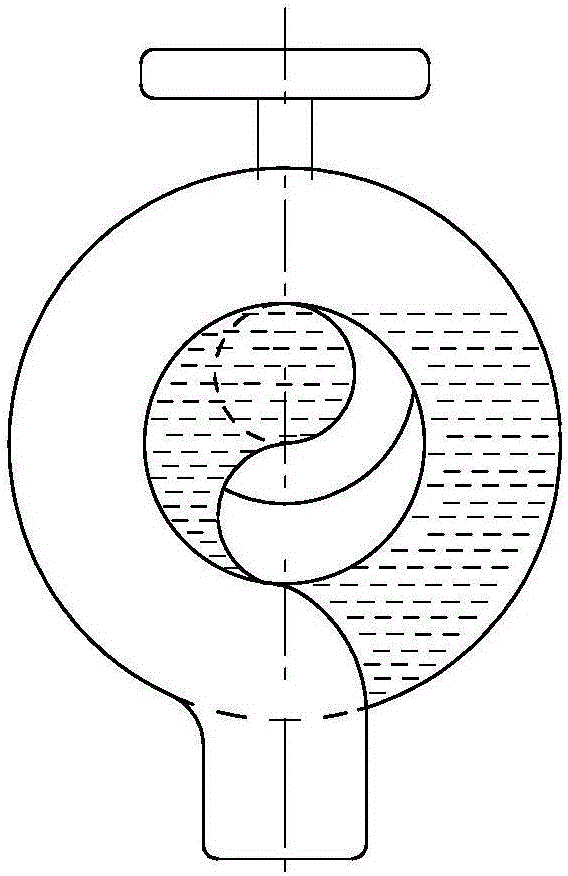

[0012] Below in conjunction with accompanying drawing, this design is illustrated.

[0013] like figure 1 , figure 2 As shown, the faucet of this design includes a handle 1 and a water outlet pipe 2. The water outlet pipe 2 is connected to a section of spiral pipe 3 that revolves in a cylindrical spiral shape. The axial direction of the spiral pipe 3 is horizontal rather than up and down. , the inner diameter of the spiral tube is larger than the inner diameter of the water outlet pipe, and the end of the spiral pipe 3 is connected to the water discharge pipe 4 that has been going downward. The height position of the cross-section, such as figure 2 As shown, during specific installation and use, the water body in the pipeline system starts to flow out when the handle 1 of the faucet is opened, and the high-pressure water flow will enter the spiral pipe 3 with an enlarged diameter along the outlet pipe 2 of the faucet. The lumen of the pipe has just become a water storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com