Assembly type hundred-level clean room

A prefabricated, clean room technology, applied in the clean room field, can solve the problems of uncontrollable clean room size, inability to rebuild and reuse, and inapplicable production lines, etc., to achieve the effects of stable connection, convenient reuse, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

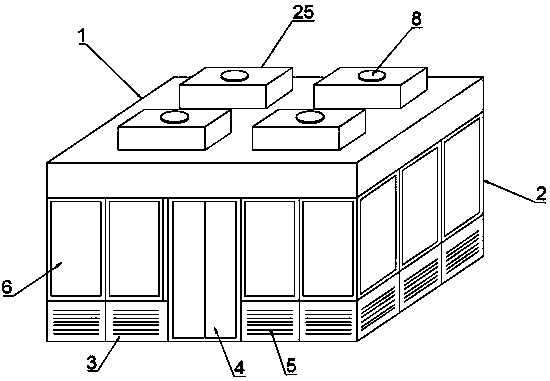

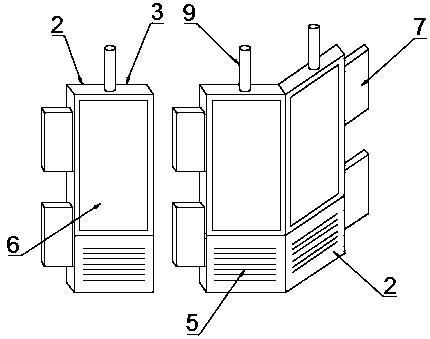

[0030] refer to Figure 1-6 , a prefabricated class 100 clean room, including a room body composed of a top plate 1, four corner plates 2 and a plurality of connecting plates 3, a connecting mechanism is provided at the joint between the corner plates 2 and the connecting plates 3, and the room body Door frame is installed on the side wall of one side, and door frame is positioned between wherein two connecting plates 3, and sliding door 4 is installed in the door frame, facilitates personnel to enter and exit the room body by opening of sliding door 4.

[0031] The connection mechanism includes two raised plates 7 integrally formed with the corner plate 2 near the side wall of the connecting plate 3, and each connecting plate 3 is provided with a hole matching the size and position of the raised plate 7 on the side close to the corner plate 2. Card slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com