Off-gas treatment system based on NTP technology and control method

A tail gas treatment and technology technology, which is applied in the electronic control of exhaust treatment devices, exhaust treatment, exhaust devices, etc., can solve problems such as acid rain and photochemical pollution, and achieve the effect of reducing PM and NOx emissions and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

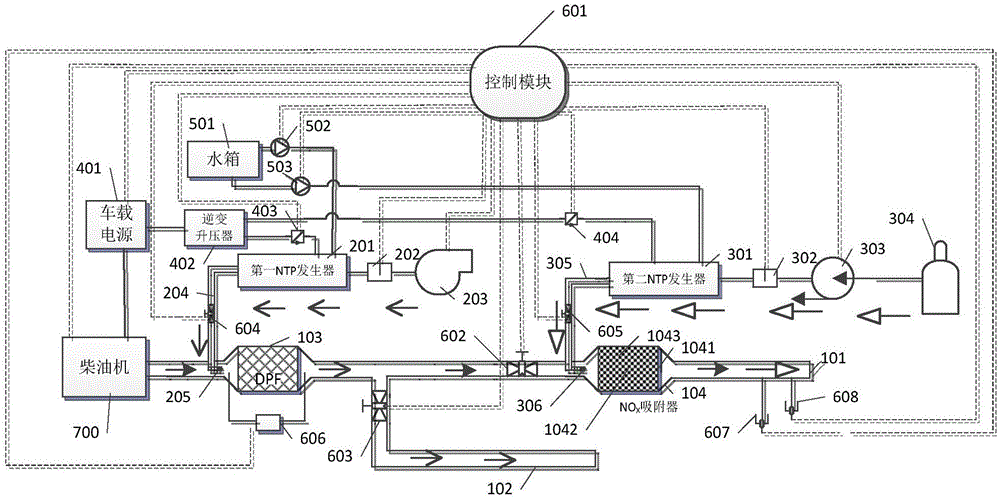

[0037] figure 1 The exhaust gas treatment system based on NTP technology of the present invention is shown, and the system includes an aftertreatment device, a first NTP injection system, a second NTP injection system, a power supply device, an NTP generator cooling system and a control system. The aftertreatment device includes a main exhaust pipe 101, a DPF 103, a NO x Adsorber 104 and exhaust branch 102. The first NTP injection system includes a first NTP generator 201 , a first mass flow controller 202 , an air supply fan 203 , a first injection pipeline 204 and a first nozzle 205 . The second NTP injection system includes a second NTP generator 301, a second mass flow controller 302, an air pump 303, N 2 A gas source 304 , a second injection pipeline 305 and a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com