A kind of high-elasticity low-shrinkage denim fabric and its technology

A denim and high-elasticity technology, applied in the field of textile fabrics, can solve the problems of garment loss in washing water, difficulty in garment manufacturing, and increased loss, and achieve the effect of avoiding increased loss and difficulty in garment manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand and recognize the structure, features and effects of the present invention, a preferred embodiment is now given, and the present invention will be further described in conjunction with specific embodiments:

[0020] A high-elasticity and low-shrinkage denim process, the specific specifications of which are: C14s*C21s+75DT400+70D 108*62 40 / 42″9.4oz / y 2 The process is: winding - warping - sizing and dyeing combination - weaving - gray cloth inspection - finishing processing - finished product inspection - packaging, of which:

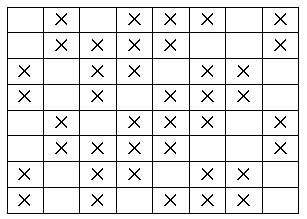

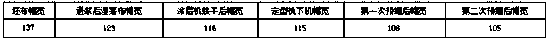

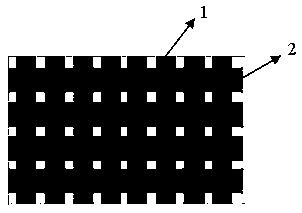

[0021] The denim is composed of warp yarn (1) and weft yarn (2), and the weaving rule is three up and one down, the weft direction extension of the denim is ≥35%, the recovery rate is ≤2.5%, and the weft shrinkage is ≤-10%. The warp yarn (1) uses 27-85tex cotton yarn or cotton and regenerated cellulose fiber blended yarn, and the blended yarn can be 65 polyester / 35 cotton, 70 polyester / 30 viscose, and 90 polyester / 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com