High-alkali-resistance wet cloth silkete penetrating agent and preparation method thereof

A mercerizing penetrating agent, high alkali-resistant technology, applied in the direction of textiles and papermaking, fiber treatment, phosphorus organic compounds, etc., can solve the problem that is not conducive to the rapid entry of lye into the fabric fiber, limit the promotion and application of wet cloth mercerizing technology, mercerizing additives Not resistant to high concentration of alkali, etc., to achieve good strong alkali resistance, high flexibility and adsorption, and uniform mercerizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] a. Esterification process: add isomeric tridecyl alcohol polyoxyethylene ether (commercially available) to deionized water, and add P in batches while stirring. 2 o 5 , after the addition, the temperature was raised to 90°C, and the temperature was kept for 4 hours to obtain the esterification product, isomerized tridecyl alcohol polyoxyethylene ether, deionized water, P 2 o 5 The molar ratio is 3:1:1;

[0025] b. Hydrolysis process: Add deionized water to hydrolyze the esterification product for 3 hours, cool down to below 50°C, neutralize the phosphate ester with 0.1M sodium hydroxide solution until the pH value is 7, and the isomerized tridecanol poly The molar ratio of oxyethylene ether to deionized water in hydrolysis is 3:1.

[0026] made (RO-(C 2 h 4 O)n) 2 PO(OH)(MAP), RO-(C 2 h 4 O)n PO(OH)(DAP), (RO-(C 2 h 4 O)n) 2 PO(OH)(MAP) and RO-(C 2 h 4 O)n PO(OH)(DAP) molar ratio is 22:1;

[0027] Said n=8;

Embodiment 2

[0029] In addition to a, in the esterification process, isomeric tridecyl alcohol polyoxyethylene ether (ROH), P 2 o 5 Except that the mol ratio is different, all the other are identical with embodiment 1, and its result is as shown in table 1:

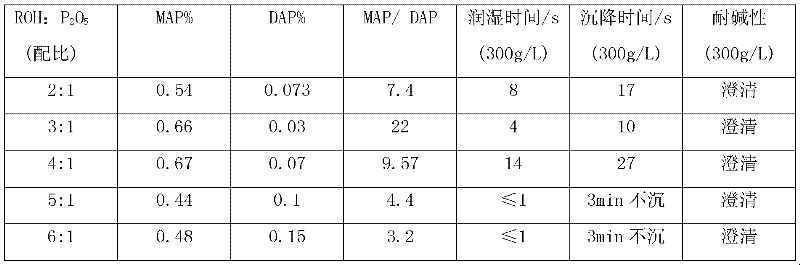

[0030] Table 1:

[0031]

[0032] It can be seen from Table 1 that there are differences in the mono- and di-ester contents and ratios of isomeric tridecanol polyoxyethylene ether and phosphorus pentoxide measured in different proportions, and the wetting time and settling time of 300g / L NaOH solution are also different. vary. With the increase of the ratio, the proportion of phosphate diester gradually decreased, but the ratio of monoester to diester gradually increased. The settling time of the standard canvas gradually decreases with the increase of MAP:DAP, but its alkali resistance basically does not change. When the ratio is 6:1 and 5:1, the wetting time of the synthetic product is very short, but the settling time of the...

Embodiment 3

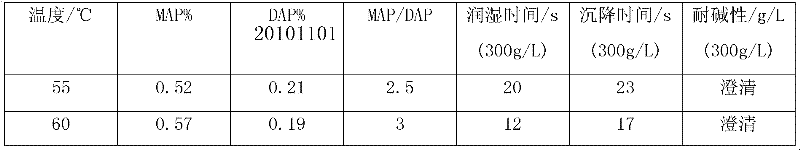

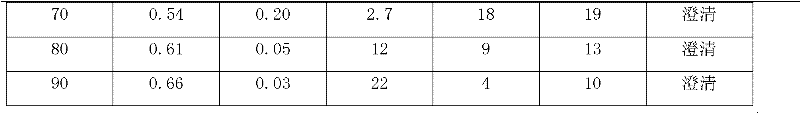

[0034] Except that the temperature in a, esterification process is different, all the other are identical with embodiment 1, and its result is as table 2.

[0035] Table 2: (300g / L sodium hydroxide solution, 3% phosphoric acid ester)

[0036]

[0037]

[0038] Since temperature is a very important process condition for organic synthesis reactions, if the temperature is too low, the reaction speed will be too slow and the esterification reaction will not be complete; if the temperature is increased, the reaction speed will be accelerated, but the phosphoric acid esterification temperature is too high to easily produce the following two Adverse effects on the aspect, it is easy to produce dehydration etherification between hydroxyl groups, so that the content of hydroxyl groups is reduced; the increase of esterification reaction temperature will also increase the rate of esterification reaction, but will produce more by-products, and the color of the product will deepen.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com