Method for preparing photonic crystal with inverse opal structure through ultraviolet radiation

A technology of inverse opal structure and photonic crystal, which is applied in the field of preparing inverse opal structure photonic crystal by ultraviolet irradiation, can solve problems such as inapplicability of inverse opal structure photonic crystal, and achieves a wide range of substrate material selection, low cost and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

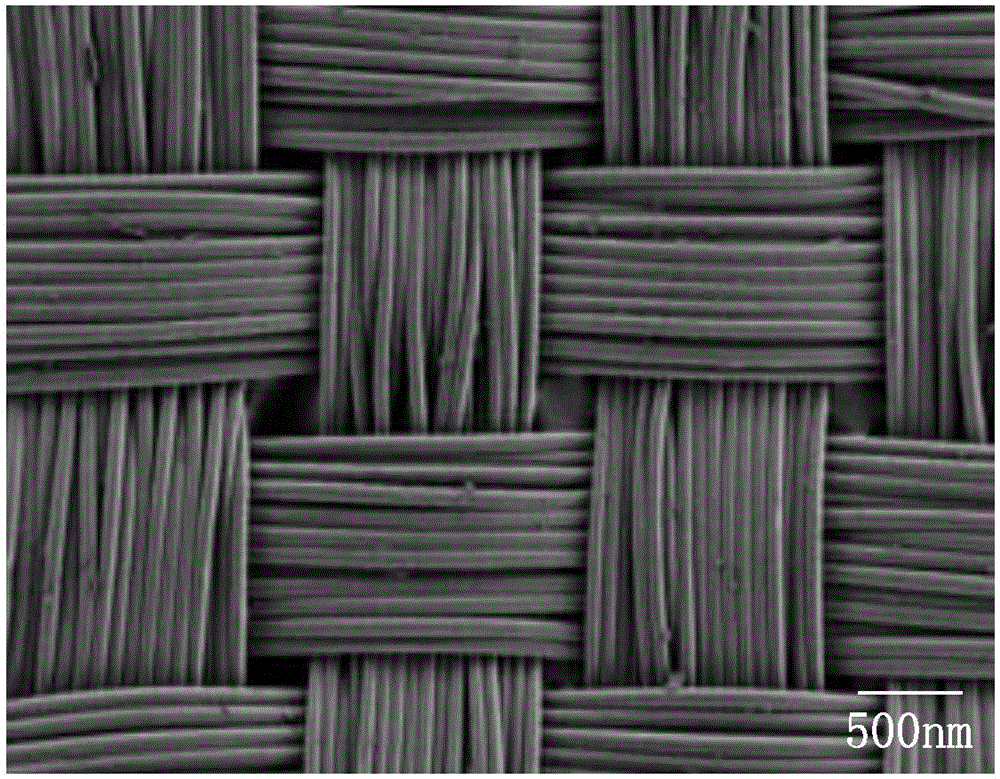

[0032] (1) Mix 1 part (in terms of solid content) of monodisperse PMMA colloidal microspheres with a particle size of 250nm (dispersion coefficients are less than 0.08) with 100 parts of deionized water, and ultrasonically disperse for 15 minutes to form a uniform dispersion of PMMA colloidal microspheres liquid.

[0033] (2) PMMA colloidal microsphere dispersion liquid is placed in the plastic Petri dish that is placed the polyester plain weave fabric, makes it immerse fabric surface, at 60 ℃, in the constant temperature and humidity chamber of 50% relative humidity, carry out vertical deposition self-assembly, wait for After the solvent evaporated for 36 h, the ordered PMMA opal structure photonic crystal template was deposited and formed.

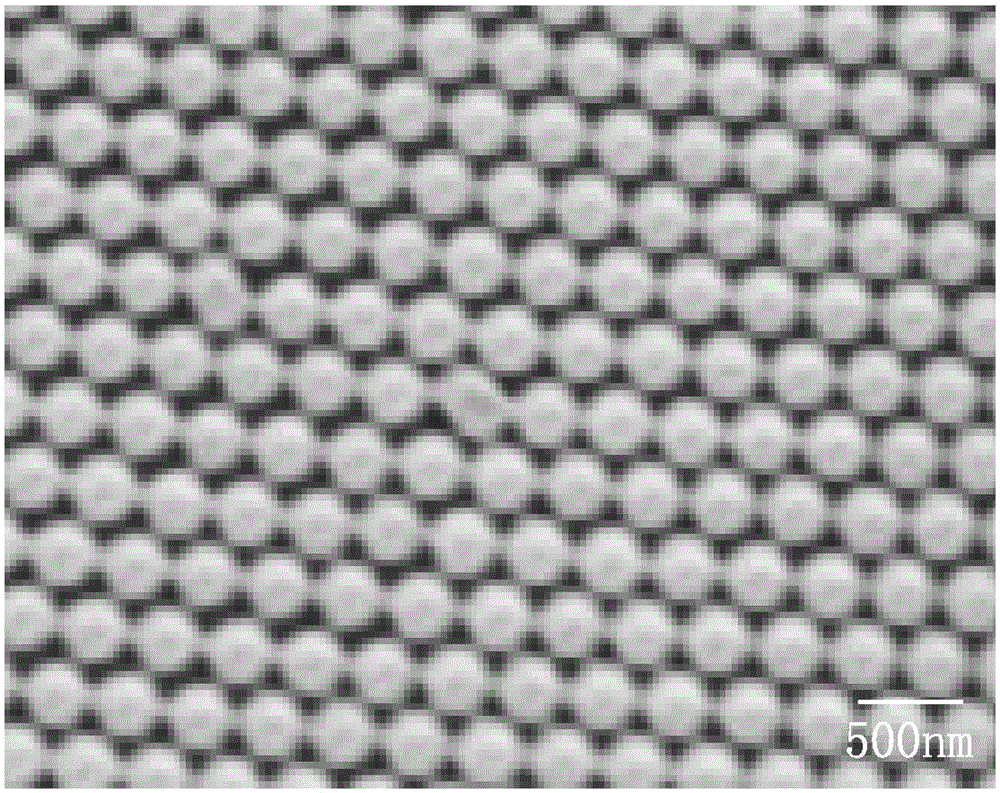

[0034] (3) Use 10% SiO with a particle size of 15nm 2 The colloidal microspheres were dropped onto the PMMA opal structure photonic crystal template for infiltration, and dried at room temperature.

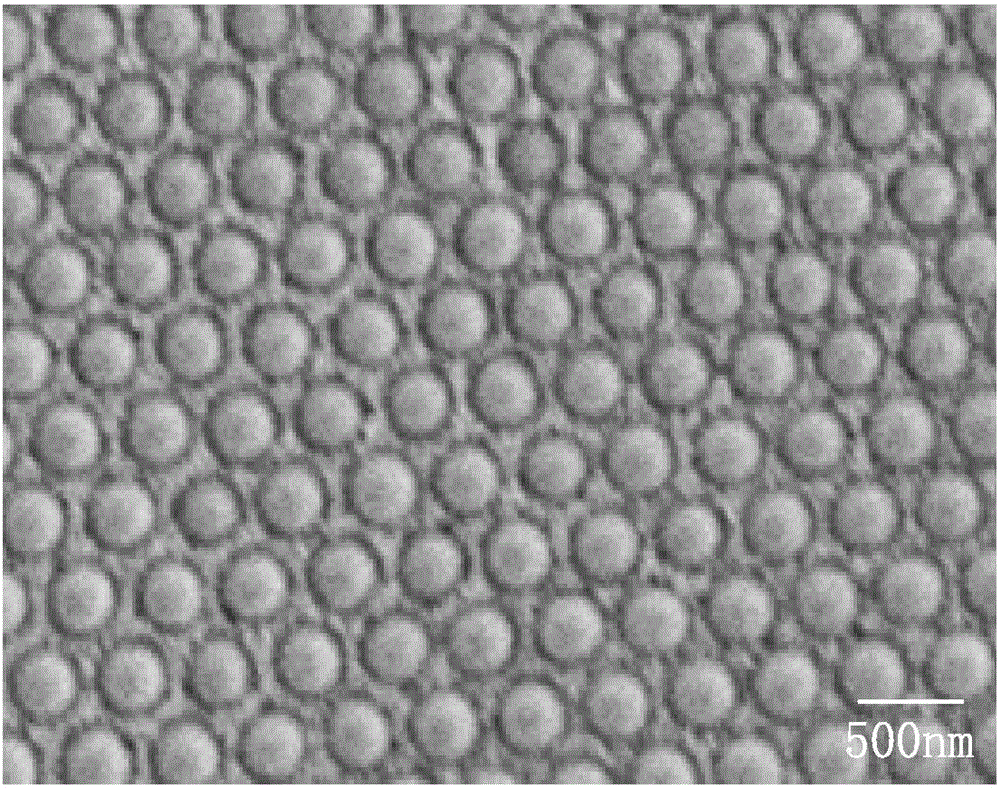

[0035] (4) The initial PMMA opal st...

Embodiment 2

[0037] (1) Mix 10 parts (in terms of solid content) of monodisperse PMMA colloidal microspheres (dispersion coefficient less than 0.08) with a particle size of 315nm and 100 parts of deionized water, and ultrasonically disperse for 15 minutes to form a uniform dispersion of PMMA colloidal microspheres .

[0038] (2) The PMMA colloidal microsphere dispersion is placed in a plastic petri dish with a polyester plain weave fabric, so that it is immersed in the surface of the fabric, and vertical deposition self-assembly is carried out in a constant temperature and humidity chamber at 45 ° C and a relative humidity of 60%. After the solvent was evaporated for 72 hours, an ordered PMMA opal structure photonic crystal template was deposited and formed.

[0039] (3) Use 20% SiO with a particle size of 60nm 2 The colloidal microspheres were dropped onto the PMMA opal structure photonic crystal template for infiltration, and dried at room temperature.

[0040] (4) The initial PMMA opa...

Embodiment 3

[0042] (1) Mix 1 part (in terms of solid content) of monodisperse PMMA colloidal microspheres (dispersion coefficient less than 0.08) with a particle size of 500nm and 100 parts of deionized water, and ultrasonically disperse for 15 minutes to form a uniform dispersion of PMMA colloidal microspheres .

[0043] (2) The PMMA colloidal microsphere dispersion was placed in a plastic petri dish with a polyester plain weave fabric to immerse the surface of the fabric, and vertical deposition self-assembly was carried out in a constant temperature and humidity chamber at 50°C and a relative humidity of 40%. After the solvent was evaporated for 48 hours, an ordered PMMA opal structure photonic crystal template was deposited and formed.

[0044](3) Use 5% SiO with a particle size of 30nm 2 The colloidal microspheres were dropped onto the PMMA opal structure photonic crystal template for infiltration, and dried at room temperature.

[0045] (4) The initial PMMA opal structure photonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com