Steel ladle upper water nozzle quick disassembling device, system and method

A ladle and nozzle technology is applied in the field of rapid dismantling devices for ladle nozzles, which can solve the problems of low dismantling efficiency of the nozzle on the ladle, and achieve the effects of reducing labor risks, improving coordination efficiency, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

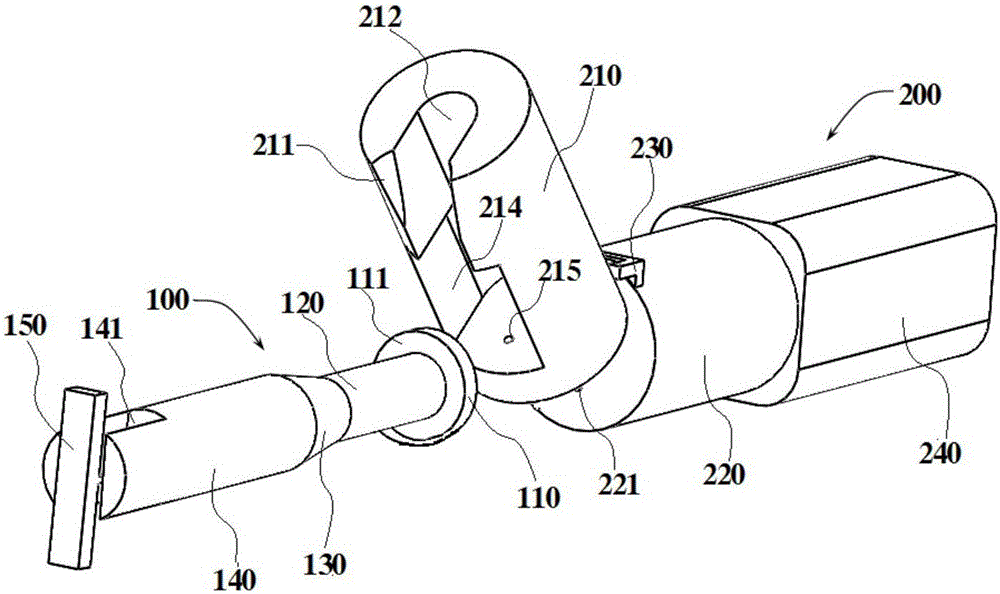

[0049] like Figure 1-Figure 5 As shown, a ladle upper nozzle removal device of the present invention includes a nozzle drawing unit 100 and a drawing drive unit 200, and the nozzle drawing unit 100 includes a pull rod stress retaining ring 110, a card slot matching a pull rod 120, a retaining The plate is connected with the pull rod 140 and the nozzle drawing baffle 150, and the force retaining ring 110 of the pull rod is connected with the baffle connection rod 140 through the slot matching pull rod 120, and the slot is matched with the pull rod 120 and the baffle is connected with the pull rod 140. A tapered connecting rod 130 is provided, and the tapered connecting rod 130 is matched with the sliding fitting arc surface 211 (such as figure 1 shown). The above-mentioned nozzle pull-out baffle 150 is arranged on the end of the baffle connection rod 140 far away from the force retaining ring 110 of the pull rod, and the nozzle pull-out baffle 150 and the baffle connection ro...

Embodiment 2

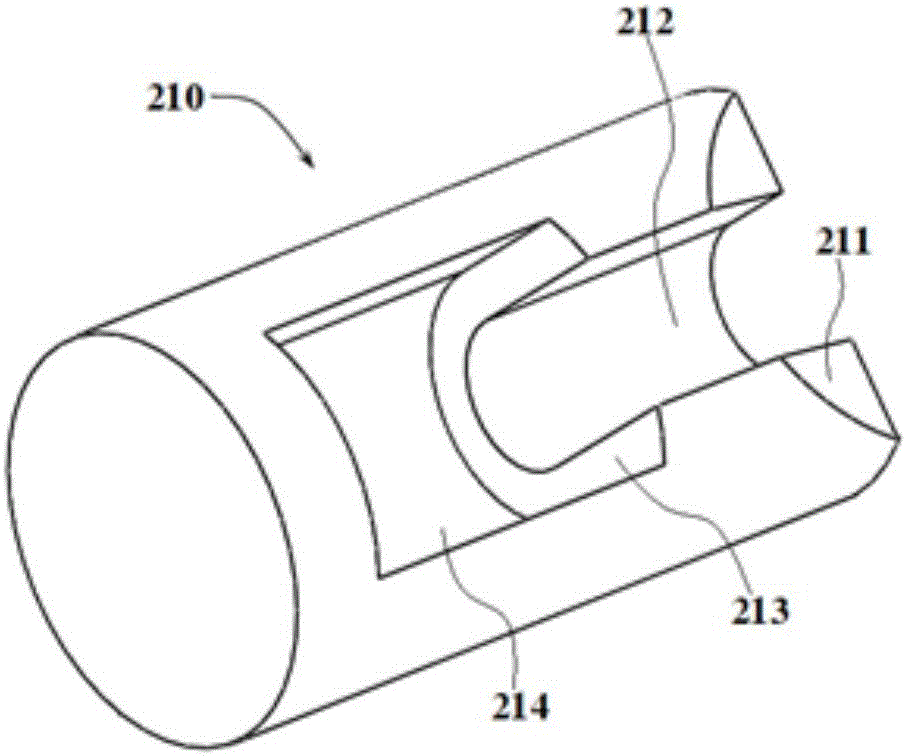

[0055] like Image 6 As shown, the tie rod force retaining ring 110 of this embodiment is provided with a tie rod limit protrusion 112, and the tie rod limit protrusion 112 is matched with the force application groove 212, and the tie rod limit protrusion 112 is used to limit the force of the pull rod The retaining ring 110 rotates relative to the pull rod engaging member 210 . And the end of the pull rod limit projection 112 close to the baffle plate connecting pull rod 140 is provided with a bump guide rod 113, and the bump guide rod 113 is used to guide the pull rod limit bump 112 into the force application groove 212, thereby limiting the force on the pull rod. The retaining ring 110 rotates relative to the tie rod fastening member 210. Because the tie rod is stressed, the retaining ring 110 is easy to rotate relative to the tie rod fastening member 210 during the force application process after the tie rod fastening member 210 cooperates. This rotation is very easy to cau...

Embodiment 3

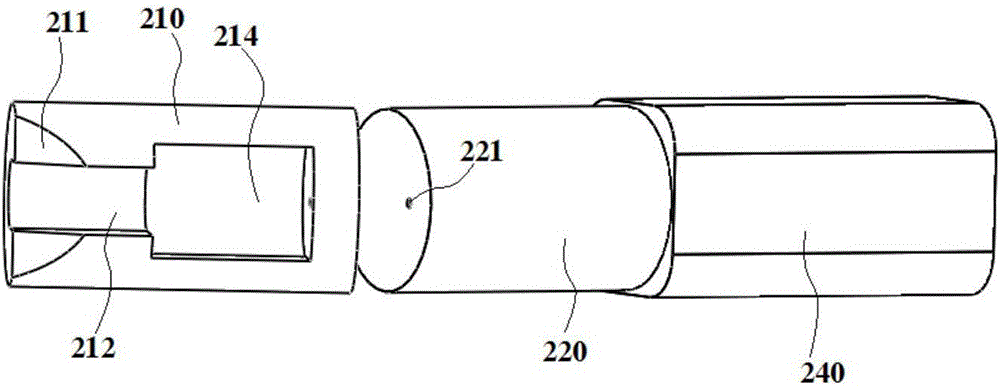

[0057] like Figure 7 As shown, the oil cylinder retraction rod 220 of this embodiment is provided with a positioning screw hole 221, the pull rod fastening member 210 is provided with a positioning matching hole 215 matching with the positioning screw hole 221, and the positioning screw 216 is matched with the positioning screw hole 221 , the positioning screw 216 passes through the positioning matching hole 215 and cooperates with the positioning screw hole 221, thereby fixing the pull rod fastening member 210 on the retractable pull rod 220 of the oil cylinder, effectively preventing the pull rod fastening when the pulling drive cylinder 240 drives the pull rod fastening member 210 The component 210 rotates relative to the fastening rotation pivot 230, so as to ensure that the pull rod fastening member 210 evenly applies a pulling force to the pull rod force retaining ring 110 to ensure the uniformity of the pulling force, thereby preventing the equipment from being damaged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com