Non-excavation reverse dismantling method for ultra-deep vertical shaft

A non-excavation, shaft technology, applied in shaft equipment, earthwork drilling, mining equipment, etc., can solve the problems of difficult development of underground space, large impact on the surrounding environment, large space occupation, etc., and achieve significant economic and social benefits, Ingenious construction method and the effect of improving demolition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

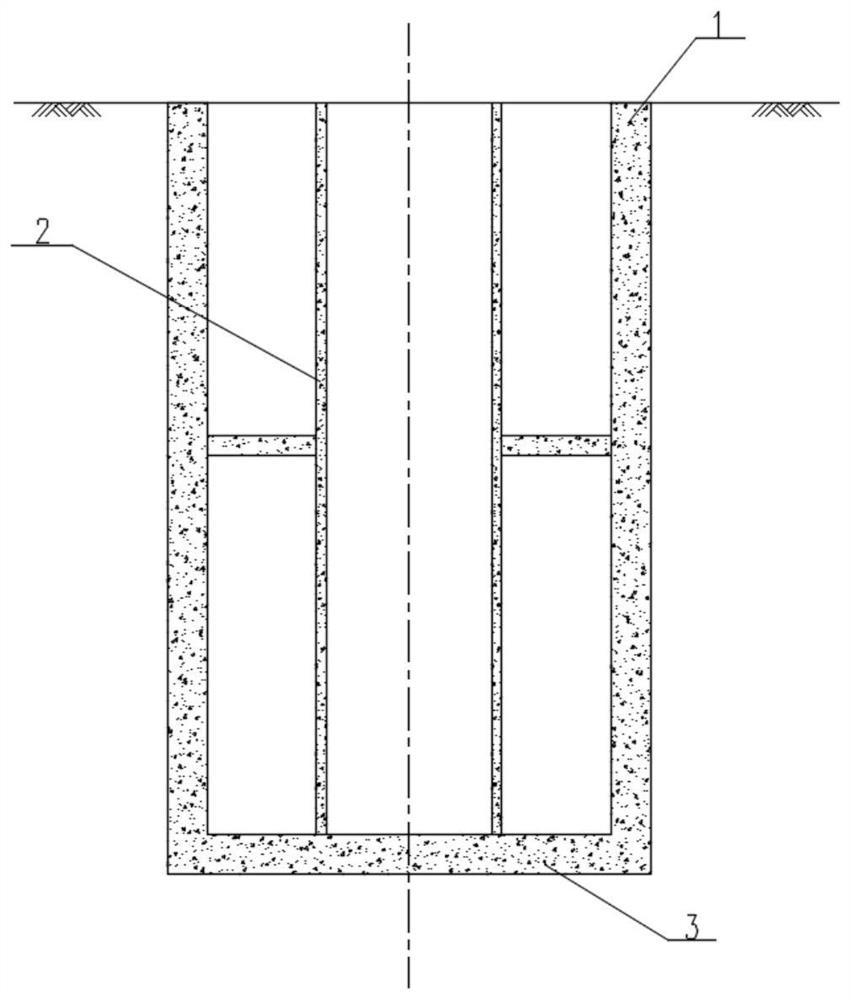

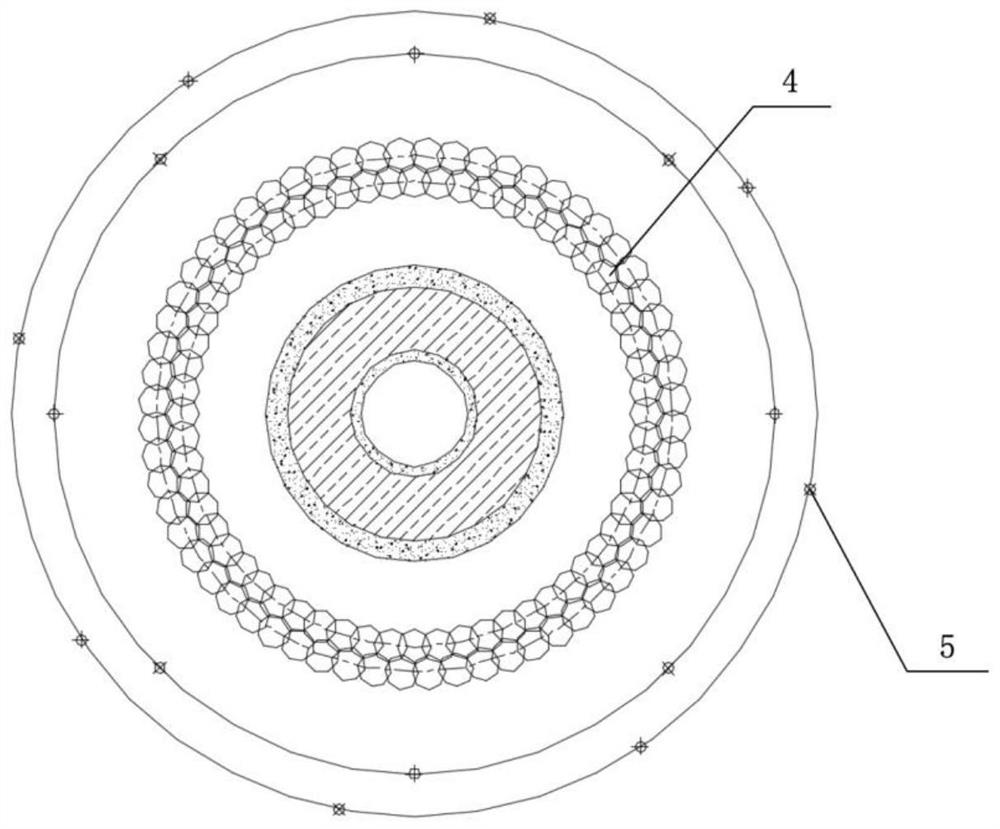

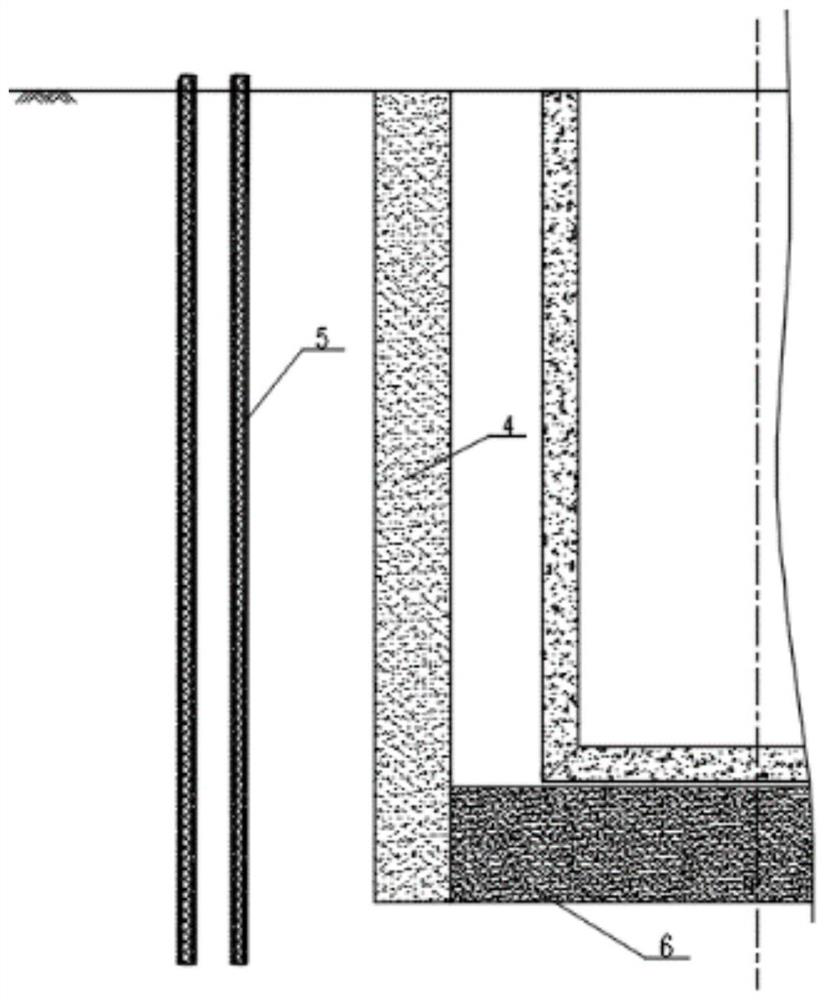

[0031] see Figure 1 to Figure 9 , a trenchless reverse demolition method for ultra-deep shafts, comprising the following steps:

[0032] 1) Seal and strengthen the soil around the ultra-deep shaft and within the set range below the bottom of the shaft

[0033] Carry out grouting or jet grouting reinforcement to the soil around the shaft wall 1 on the outer side of the ultra-deep shaft and within the set range below the bottom plate 3 of the shaft, and form a closed reinforced soil around the shaft 4 and a reinforced soil 6 below the shaft on the outer side of the ultra-deep shaft . The reinforcement process and reinforcement range should be reasonably determined after calculation and review in combination with the characteristics of the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com