Preparation method of solid amino carbon dioxide capture material

An amine-based carbon dioxide and solid-state technology, applied in chemical instruments and methods, separation methods, alkali metal oxides/hydroxides, etc., can solve the problem of adsorption capacity, adsorption kinetics rate to be further improved, and poor cycle stability of adsorbents , Complicated preparation process of adsorbent and other issues, to achieve the effect of strong large-scale preparation feasibility, easy operation, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

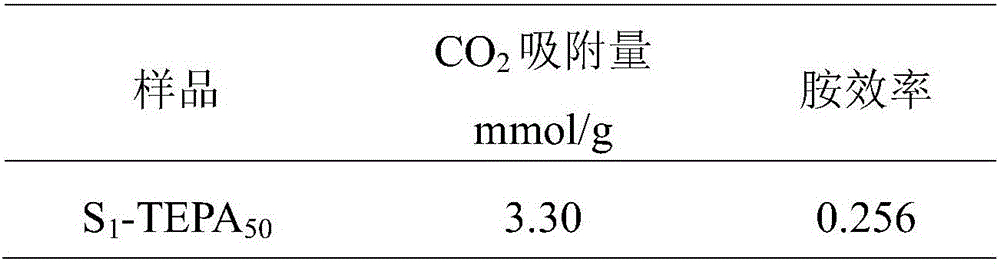

[0024] Example 1. Prepare a glucose solution with a concentration of 1M, transfer it into a reaction kettle lined with polytetrafluoroethylene, and conduct a hydrothermal reaction at 150° C. for 10 hours to prepare carbon spheres. Dissolve carbon spheres, cetyltrimethylammonium bromide, and tetraethyl orthosilicate in a mixed solution of methanol / ethanol (methanol:ethanol volume ratio is 1:1), then add concentrated ammonia water, and stir to react 24h, filter, and roast at 500°C for 6h to prepare silicon oxide hollow spheres, wherein the mass ratio of carbon spheres: hexadecyltrimethylammonium bromide: tetraethylorthosilicate: methanol / ethanol mixed solution: concentrated ammonia water is 10: 1:1:400:10, named S 1 . Add silica hollow spheres into a mixed solution composed of tetraethylenepentamine and ethanol, stir for 2 hours, and dry at 100°C for 24 hours to prepare silica hollow spheres loaded amine-type adsorbent, wherein silica hollow spheres: tetraethylenepentamine: Th...

Embodiment 2

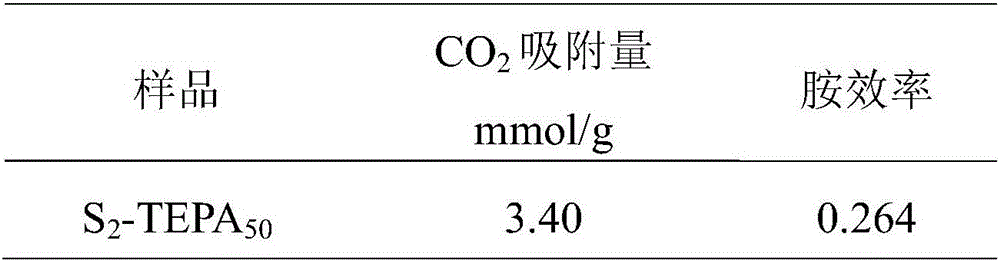

[0028] Example 2. Prepare a glucose solution with a concentration of 2M, transfer it into a reaction kettle with a polytetrafluoroethylene liner, and conduct a hydrothermal reaction at 160° C. for 12 hours to prepare carbon spheres. Dissolve carbon spheres, cetyltrimethylammonium bromide, and tetraethyl orthosilicate in a mixed solution of methanol / ethanol (methanol:ethanol volume ratio is 1:2), then add concentrated ammonia water, and stir to react 12h, filter, and roast at 520°C for 3h to prepare silicon oxide hollow spheres, wherein the mass ratio of carbon spheres: hexadecyltrimethylammonium bromide: tetraethylorthosilicate: methanol / ethanol mixed solution: concentrated ammonia water is 12: 1.2:1:400:12, named S 2 . Add silicon oxide hollow spheres into a mixed solution composed of tetraethylenepentamine and ethanol, stir for 1 hour, and dry at 80°C for 28 hours to prepare silicon oxide hollow spheres loaded amine-type adsorbent, wherein silicon oxide hollow spheres: tetr...

Embodiment 3

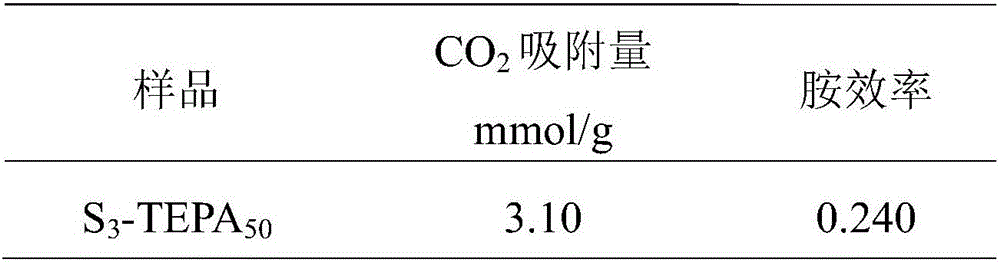

[0032] Example 3. Prepare a glucose solution with a concentration of 3M, transfer it into a reaction kettle with a polytetrafluoroethylene liner, and conduct a hydrothermal reaction at 170° C. for 15 hours to prepare carbon spheres. Dissolve carbon spheres, cetyltrimethylammonium bromide, and tetraethyl orthosilicate in a mixed solution of methanol / ethanol (methanol:ethanol volume ratio is 1:1.5), then add concentrated ammonia water, and stir the reaction 16h, filter, and roast at 550°C for 4h to prepare silicon oxide hollow spheres, wherein the mass ratio of carbon spheres: hexadecyltrimethylammonium bromide: tetraethylorthosilicate: methanol / ethanol mixed solution: concentrated ammonia water is 14: 1.4:1:400:14, named S 3 . Add silicon oxide hollow spheres into a mixed solution composed of tetraethylenepentamine and ethanol, stir for 1.4 hours, and dry at 85°C for 32 hours to prepare silicon oxide hollow spheres loaded amine-type adsorbent, wherein silicon oxide hollow sphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com