Method and device for removing SO2 in smoke gas by pyrolusite slurry and resource utilization

A technology of resource utilization and pyrolusite, applied in chemical instruments and methods, separation methods, manganese sulfate, etc., can solve the problems of large investment and energy consumption, loss of ammonia volatilization, high cost, etc., and achieve low operating costs and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

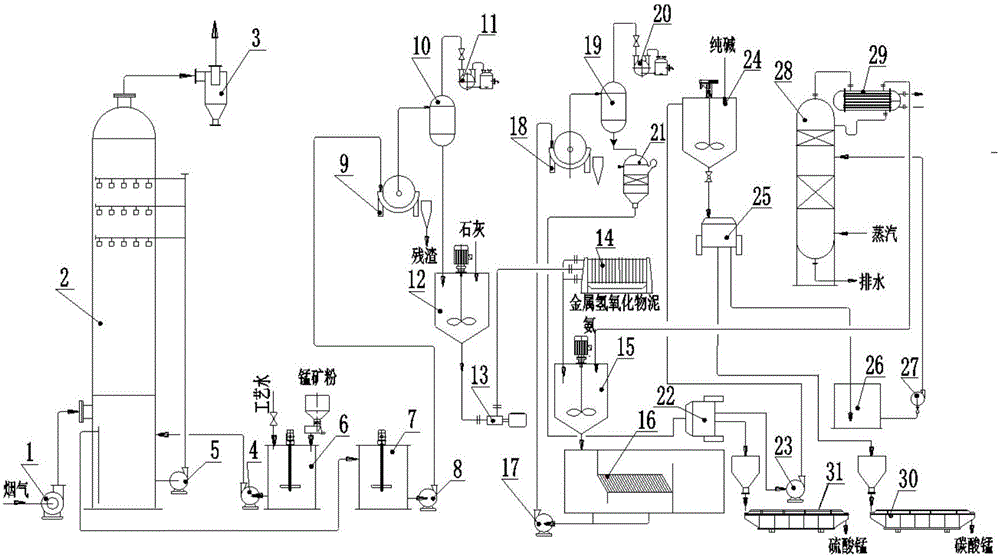

[0027] Such as Figure 1 As shown, a manganese ore slurry removes SO from flue gas 2And the device for resource utilization, including pressurized blower 1, desulfurization tower 2, demister 3, slurry pump I4, circulation pump 5, slurry mixing tank 6, desulfurization slurry storage tank 7, slurry pump II8, vacuum filter I9 , receiving tank I10, vacuum pump I11, purification tank 12, screw pump 13, filter press 14, neutralization tank 15, clarification sedimentation tank 16, slurry pump III17, vacuum filter II18, receiving tank II19, vacuum pump II20, vacuum evaporator 21. Centrifuge I22, clear liquid pump 23, carbonization tank 24, centrifuge II25, mother liquid tank 26, ammonia gas pump 27, ammonia distillation tower 28, shrinker 29, dryer I30, dryer II31; pressurized blower 1 and The lower part of the desulfurization tower 2 is connected, the bottom of the desulfurization tower 2 is equipped with a material storage box, and the upper part is equipped with a spray device. Th...

Embodiment 2

[0036] The manganese ore slurry described in this embodiment removes SO in the flue gas 2 And the method of resource utilization thereof, adopting device and embodiment 1 except that two rows of spraying devices are set, and each row is set with 7 sprinklers, the others are all the same, and the specific steps are as follows:

[0037] (1) Utilize the ball mill to wet-grind the pyrolus ore, pass through a 200-mesh sieve, add water to make pyrolusite slurry in the pulp mixing tank 6, the solid content of the pyrolusite slurry is 22%, and the pH value of the adjusted pyrolusite slurry is 4;

[0038] (2) The flue gas is the flue gas of the power plant boiler, and the flue gas volume is 100000Nm 3 / h, SO in flue gas 2 The content is 2000mg / Nm 3 , with an average temperature of 120°C, and it is required to discharge flue gas SO 2 Less than 400mg / Nm 3 , the flue gas with a higher temperature first enters the waste heat exchanger to generate low-pressure steam for use in the evapo...

Embodiment 3

[0044] The manganese ore slurry described in this embodiment removes SO in the flue gas 2 The method for resource utilization thereof adopts the device identical to that of embodiment 1, and the concrete steps are as follows:

[0045] (1) Utilize the ball mill to wet-grind the pyrolusite, pass through a 200-mesh sieve, add water in the slurry mixing tank 6 to make pyrolusite slurry, the solid content of the pyrolusite slurry is 18%, and the pH value of the pyrolusite slurry is adjusted to 4.5;

[0046] (2) The flue gas is flue gas from a sulfuric acid production plant, and the sulfuric acid tail gas treatment capacity is 200,000Nm 3 / h, SO in the tail gas of the two-rotation and two-suction sulfuric acid unit 2 Content 650mg / Nm 3 , the exhaust gas outlet requires SO 2 Content 100mg / Nm 3 Below, the desulfurization efficiency is more than 85%. The flue gas with a higher temperature first enters the waste heat exchanger to generate low-pressure steam for use in the evaporatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com