Lithium ion power battery and preparation method thereof

A power battery and lithium-ion technology, which is applied in the field of lithium-ion power batteries and their preparation, can solve the problems of poor battery performance, poor electrical conductivity, and large specific surface area, and achieve no environmental pollution, long cycle life, and high energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method for a lithium-ion power battery, comprising the following steps:

[0035] 1) Take the first active material, the first binder, the first conductive agent, the second active material, the second binder and the second conductive agent in the formulated amount respectively, and bake them in an environment of 115-125°C 11-13h, standby;

[0036] 2) Preparation of positive electrode slurry: take the first active material, the first binder and the first conductive agent baked in step 1), and mix them to obtain the first mixed powder; take N-methylpyrrolidone or remove Ionized water is used as the first solvent, and the first mixed powder is mixed with the first solvent, and after stirring evenly, a positive electrode slurry is obtained;

[0037] 3) Prepare the positive electrode sheet: take the positive electrode slurry, apply it evenly on the positive electrode current collector, dry, then place it on a roller press for rolling, and finally slice it to o...

Embodiment 1

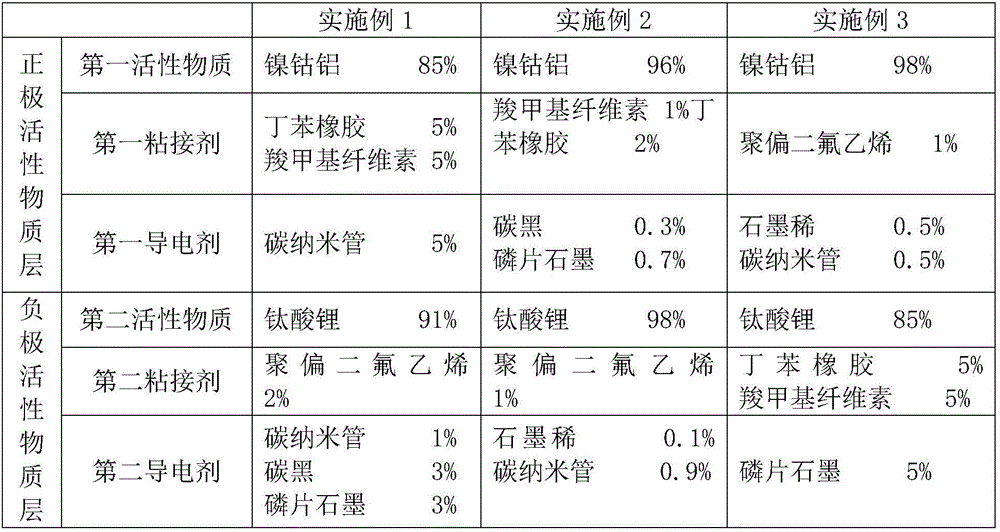

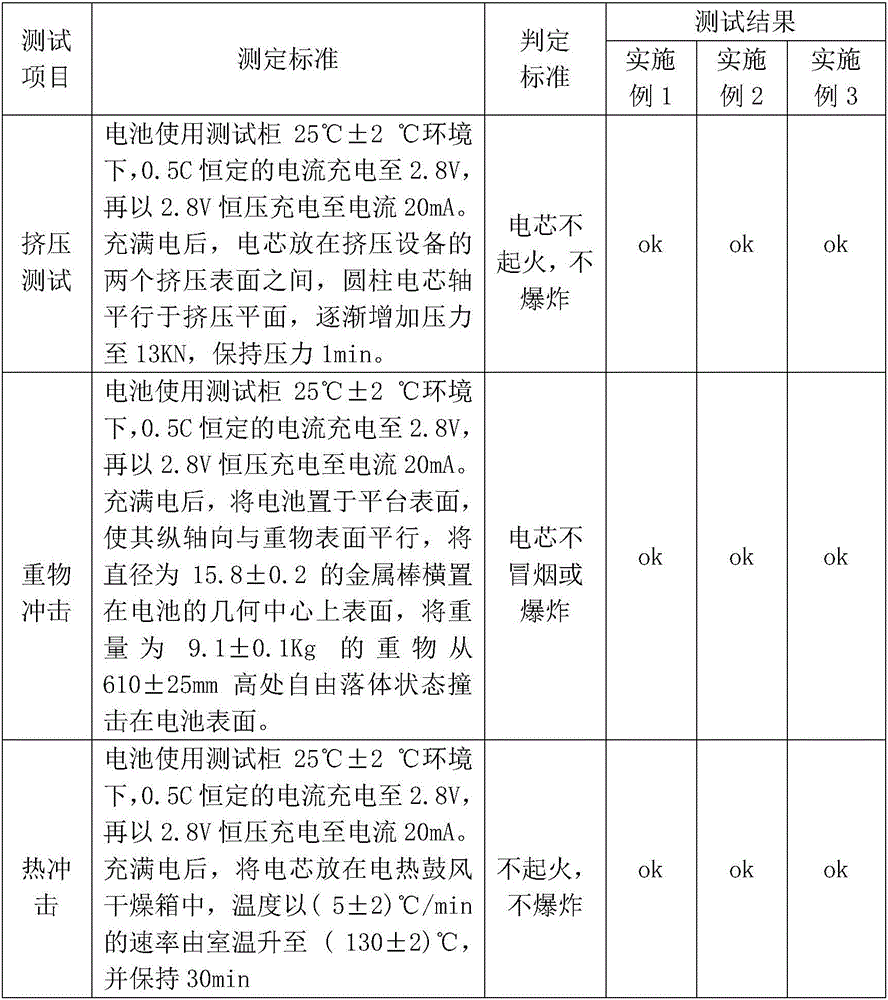

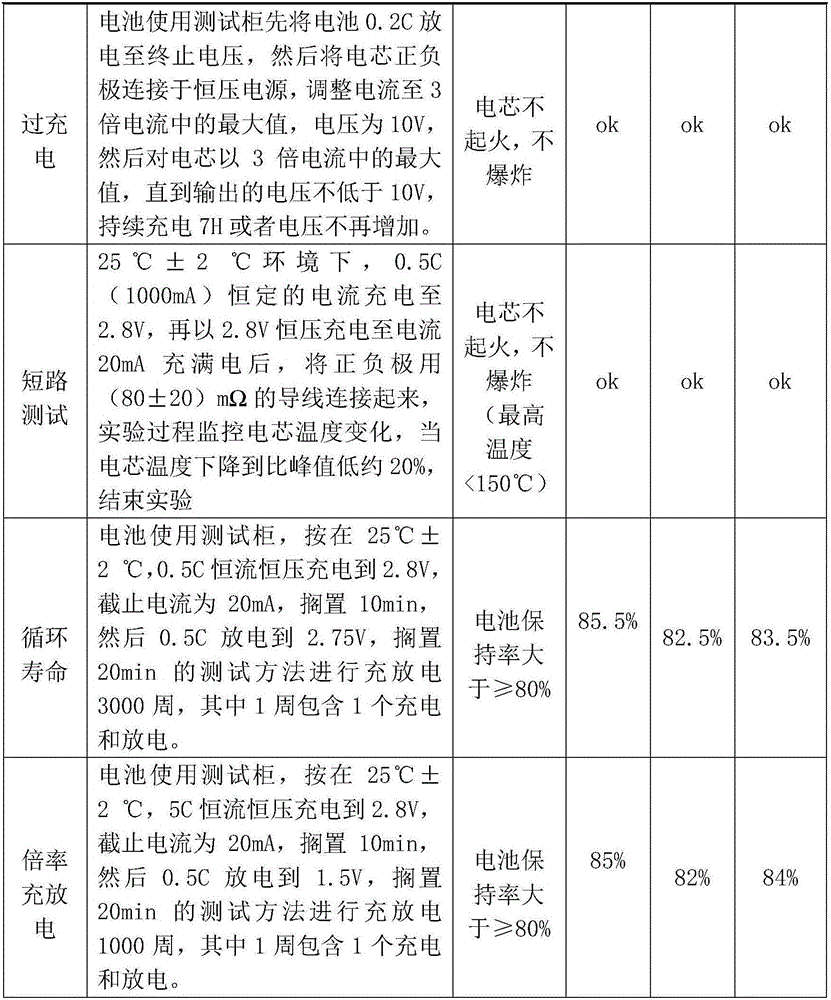

[0043] A lithium-ion power battery, comprising a positive electrode sheet and a negative electrode sheet; the positive electrode sheet includes a positive electrode collector and a positive active material layer arranged on the surface of the positive electrode collector; the negative electrode sheet includes a negative electrode collector and is arranged on the The negative electrode active material layer on the surface of the negative electrode current collector. The formulations of the positive active material layer and the negative active material layer are shown in Table 1. The lithium-ion power battery is prepared according to the following steps:

[0044] 1) Take the first active material, the first binder, the first conductive agent, the second active material, the second binder and the second conductive agent in the formulated amount respectively, and bake them in an environment of 120°C for 12 hours, spare;

[0045] 2) Preparation of positive electrode slurry: take...

Embodiment 2

[0052] The difference between Example 2 and Example 1 is that: the formulations of the positive electrode active material layer and the negative electrode active material layer are different, see Table 1 for details;

[0053] The preparation steps differ, including the following distinctions:

[0054] In step 1), the baking temperature is 125° C., and the baking time is 11 hours;

[0055] In step 2), the first solvent is deionized water, and the weight of the first solvent is 30% of the weight of the first mixed powder;

[0056] In step 3), the thickness of the positive electrode collector is 13um, and the density of the positive electrode slurry on the positive electrode collector is 2g / 100cm 2 ;

[0057] In step 4), the first solvent is deionized water, and the weight of the second solvent is 30% of the weight of the second mixed powder;

[0058] In step 5), the thickness of the negative electrode collector is 12um, and the density of the negative electrode slurry on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com