Preparation method and product of high-performance metal grid transparent conductive film

A technology of transparent conductive film and metal mesh, applied in metal/alloy conductor, cable/conductor manufacturing, conductive layer on insulating carrier, etc., which can solve the problems of inflexibility and visible metal mesh.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

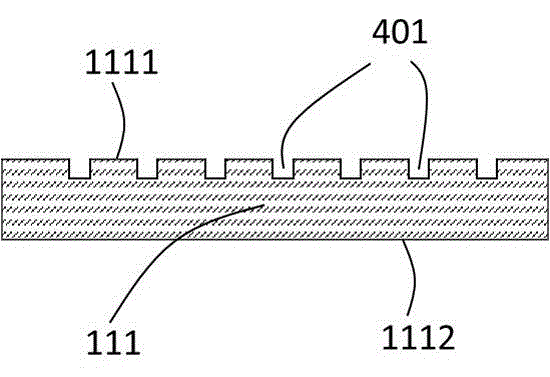

[0058] The metal grid transparent conductive thin film structure of this embodiment is as Figure 7 (a), where,

[0059] 105 is a PET transparent substrate with a thickness of 125 microns, 1051 is the first surface of the PET transparent substrate, and 1052 is the second surface of the PET transparent substrate;

[0060] 301 is a groove layer, the material of the groove layer is UV curable glue, and its thickness is 20 microns, and the groove layer 301 is located on the first surface 1051 of the PET transparent substrate;

[0061] 206 is a metal grid wiring, and the metal grid wiring is formed by close contact between graphene and metal nanoparticles grown on it in situ, and its structural schematic diagram is as follows Figure 4 shown. The metal mesh wiring 206 is completely contained within the surface of the groove layer 301 .

[0062] The specific preparation method is as follows:

[0063] S1, providing a PET transparent substrate comprising a first surface and a seco...

Embodiment 2

[0073] The metal grid transparent conductive thin film structure of this embodiment is as Figure 7 (a), where,

[0074] 105 is a PET transparent substrate with a thickness of 125 microns, 1051 is the first surface of the PET transparent substrate, and 1052 is the second surface of the PET transparent substrate;

[0075] 301 is a groove layer, the material of the groove layer is UV curable glue, and its thickness is 20 microns, and the groove layer 301 is located on the first surface 1051 of the PET transparent substrate;

[0076] 206 is a metal grid grid wiring, and the metal grid wiring is formed by close contact between graphene and gold nanoparticles grown on it in situ, and its structural schematic diagram is as follows Figure 4 As shown, the average diameter of the gold nanoparticles is 20 nm, and the average size of the graphene is 500 nm. The metal mesh wiring 206 is completely contained within the surface of the groove layer 301 .

[0077] The specific preparation...

Embodiment 3

[0082] The metal grid transparent conductive thin film structure of this embodiment is as Figure 7 (d), where:

[0083] 108 is a PET transparent substrate with a thickness of 125 microns, 1081 is the first surface of the PET transparent substrate, and 1082 is the second surface of the PET transparent substrate;

[0084] 304 is the first groove layer, 305 is the second groove layer, the material of the first groove layer and the second groove layer is UV curing glue, and its thickness is 20 microns, and the groove layer 304 is located on the PET transparent lining. above the bottom first surface 1081;

[0085] 209 is the first metal grid wiring, which is formed by close contact between the graphene and the metal nanoparticles grown on it in situ, and its structural schematic diagram is as follows Image 6 As shown, the first metal grid wiring 209 is completely contained within the surface of the first groove layer 304;

[0086] 210 is the second metal grid wiring, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com