Underground self-moving device of coal mine

A self-moving, coal mine technology, applied to mining equipment, mine roof support, earth square drilling, etc., can solve the problems of high cost, inconvenient, troublesome maintenance and operation, etc., to facilitate transportation and installation, convenient disassembly, simple and practical design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

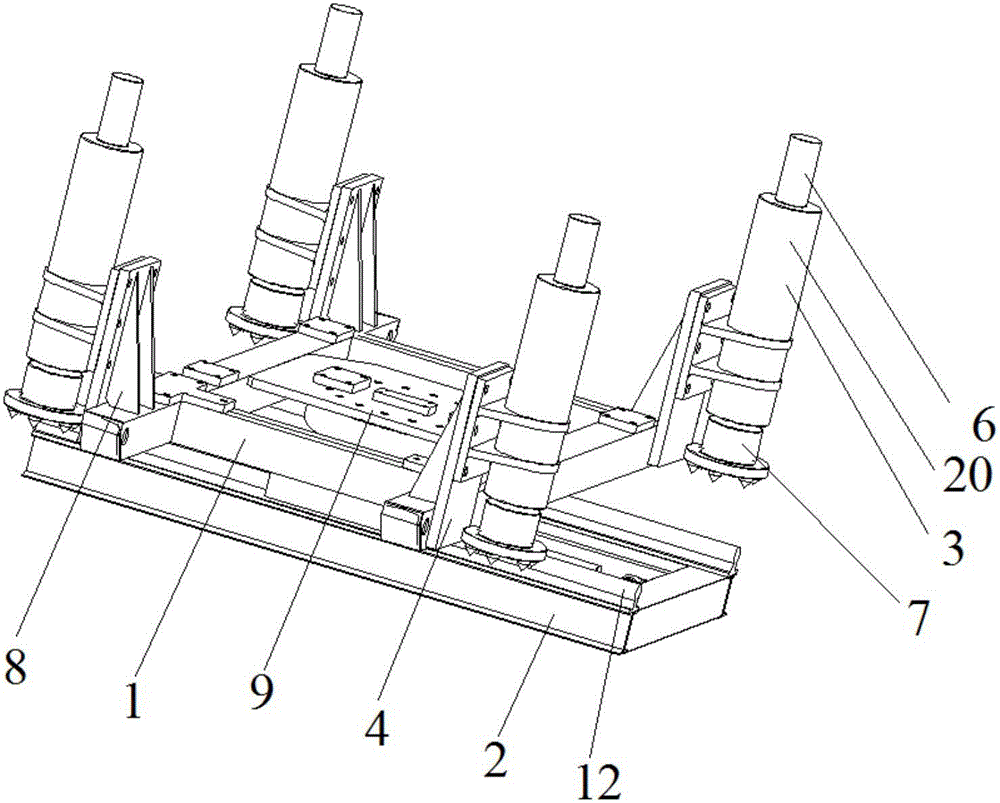

[0022] see Figure 1-3 with Figure 5 , the present invention provides a technical solution: a coal mine self-moving device, including a support frame 1 and a track frame 2, the support frame 1 and the track frame 2 are bolted through the bolt holes left on the rotary plate 9 and the rotary drive 14, The four corners of the support frame 1 are provided with support legs 3, and the middle part of the support frame 1 is provided with a revolving plate 9, and a bolt hole is left on the revolving plate 9, and the support legs 3 and the support frame 1 pass through The fixed plate 4 is bolted so that the support leg 3 can be quickly disassembled. The inside of the support leg 3 is provided with a hydraulic cylinder 20. The upper end of the support leg 3 is provided with a hydraulic interface 6, and the lower end is provided with a hydraulic telescopic claw 7. The telescopic claw The extension length of 7 can be controlled and adjusted by an external hydraulic device, and the retra...

Embodiment 2

[0031] see Figure 2-5 , the present invention provides a technical solution: a coal mine self-moving device, including a support frame 1 and a track frame 2, the support frame 1 and the track frame 2 are bolted through the bolt holes left on the rotary plate 9 and the rotary drive 14, The four corners of the support frame 1 are provided with support legs 3, and the middle part of the support frame 1 is provided with a revolving plate 9, and a bolt hole is left on the revolving plate 9, and the support legs 3 and the support frame 1 are fixed by The plate 4 is bolted so that the support leg 3 can be quickly disassembled. The inside of the support leg 3 is provided with two hydraulic cylinders 20, and the hydraulic interface 6 is located in the middle of the support leg 3. The upper and lower ends of the support leg 3 are Telescopic claws 7 are provided, which can be respectively used for fixing on the top and the ground of the mine, and two hydraulic cylinders 20 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com