Staggered tooth type thermal insulation building blocks and thermal insulation wall body bricklaying method

A technology for thermal insulation walls and thermal insulation blocks, which is applied to walls, buildings, building materials, etc., to achieve the effect of speeding up construction, simple, convenient and economical construction, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

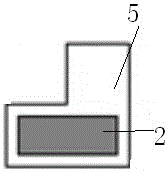

[0027] combine figure 1 and figure 2 , the staggered tooth-shaped thermal insulation block includes a staggered tooth-shaped thermal insulation main block and a staggered tooth-shaped thermal insulation matching block, and the staggered tooth-shaped thermal insulation main block includes a non-interface side horizontal thermal insulation board 1, a protruding large interface horizontal thermal insulation board 2. Recessed interface 3, large protruding interface 4 and small protruding interface 5;

[0028] One side of the staggered tooth-shaped thermal insulation main block is set to be zigzag with unequal height, and the other side is set to be straight, and a large protruding interface 4 is arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com