Cable fireproofing coating

A technology for fireproof coatings and cables, applied in the field of coatings, can solve the problems of difficulty in obtaining comprehensive performance fireproof coatings, poor bending resistance, poor strength and weather resistance of coatings, etc., to suppress efflorescence and improve adhesion and strength , Improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

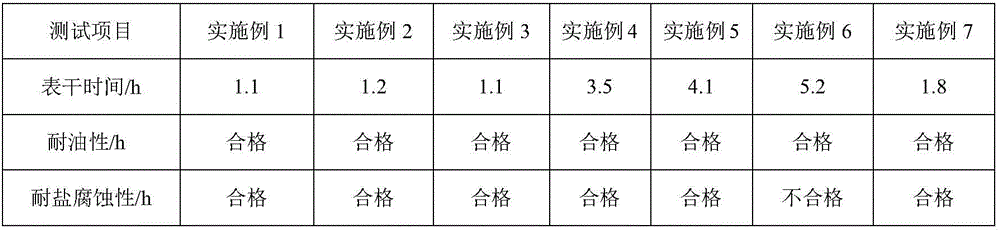

Examples

Embodiment 1

[0022] 8 parts of zinc borate, 6 parts of bentonite, 8 parts of titanium dioxide, 5 parts of molybdenum trioxide, 8 parts of dimethyl silicone oil, 2 parts of polyoxyethylene polyoxypropanolamine ether, N,N-dimethylpiperazine 3 parts, octaphenyl cage polysilsesquioxane modified sulfonated polyimide 20 parts, KH-560 18 parts, 1,12-dibromododecane 8 parts, β-cyclodextrin modified 8 parts of amino-terminated sulfonated polybenzimidazole, 40 parts of nano-titanium dioxide, 3 parts of graphene oxide, 40 parts of tetraethyl orthosilicate, 15 parts of dimethyl sulfoxide, 8 parts of ethylene glycol and 8 parts of pentaerythritol In the batching tank, it is stirred by a dispersing mixer, the stirring speed is controlled at 500 rpm, and the stirring time is 15 minutes, until it becomes sticky, that is, the cable fireproof coating;

[0023] Wherein said octaphenyl cage polysilsesquioxane modified sulfonated polyimide is prepared by the following method:

[0024] In a 100mL dry three-nec...

Embodiment 2

[0030]8 parts of zinc borate, 6 parts of bentonite, 8 parts of titanium dioxide, 5 parts of molybdenum trioxide, 8 parts of dimethyl silicone oil, 2 parts of polyoxyethylene polyoxypropanolamine ether, N,N-dimethylpiperazine 3 parts, octaphenyl cage polysilsesquioxane modified sulfonated polyimide 20 parts, KH-560 18 parts, 1,12-dibromododecane 8 parts, β-cyclodextrin modified 8 parts of amino-terminated sulfonated polybenzimidazole, 40 parts of nano-titanium dioxide, 3 parts of graphene oxide, 40 parts of tetraethyl orthosilicate, 15 parts of dimethyl sulfoxide, 8 parts of ethylene glycol and 8 parts of pentaerythritol In the batching tank, it is stirred by a dispersing mixer, the stirring speed is controlled at 500 rpm, and the stirring time is 15 minutes, until it becomes sticky, that is, the cable fireproof coating;

[0031] Wherein, the octaphenyl cage polysilsesquioxane modified sulfonated polyimide is prepared by the following method:

[0032] In a 100mL dry three-neck...

Embodiment 3

[0038] 8 parts of zinc borate, 6 parts of bentonite, 8 parts of titanium dioxide, 5 parts of molybdenum trioxide, 8 parts of dimethyl silicone oil, 2 parts of polyoxyethylene polyoxypropanolamine ether, N,N-dimethylpiperazine 3 parts, octaphenyl cage polysilsesquioxane modified sulfonated polyimide 20 parts, KH-560 18 parts, 1,12-dibromododecane 8 parts, β-cyclodextrin modified 8 parts of amino-terminated sulfonated polybenzimidazole, 40 parts of nano-titanium dioxide, 3 parts of graphene oxide, 40 parts of tetraethyl orthosilicate, 15 parts of dimethyl sulfoxide, 8 parts of ethylene glycol and 8 parts of pentaerythritol In the batching tank, it is stirred by a dispersing mixer, the stirring speed is controlled at 500 rpm, and the stirring time is 15 minutes, until it becomes sticky, that is, the cable fireproof coating;

[0039] Wherein, the octaphenyl cage polysilsesquioxane modified sulfonated polyimide is prepared by the following method:

[0040] In a 100mL dry three-nec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com