Preparation method of color-variable PU colorful wood lacquer base varnish

A wood paint and color-changing technology, applied in the direction of multi-color effect paints, coatings, polyester paints, etc., can solve problems such as dull luster, not too high hardness, poor flexibility, etc., to achieve high hardness and high gloss , the effect of high cross-linking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of above-mentioned transparent base varnish comprises the following steps:

[0029] A. Select a clean and standard dispersion cylinder;

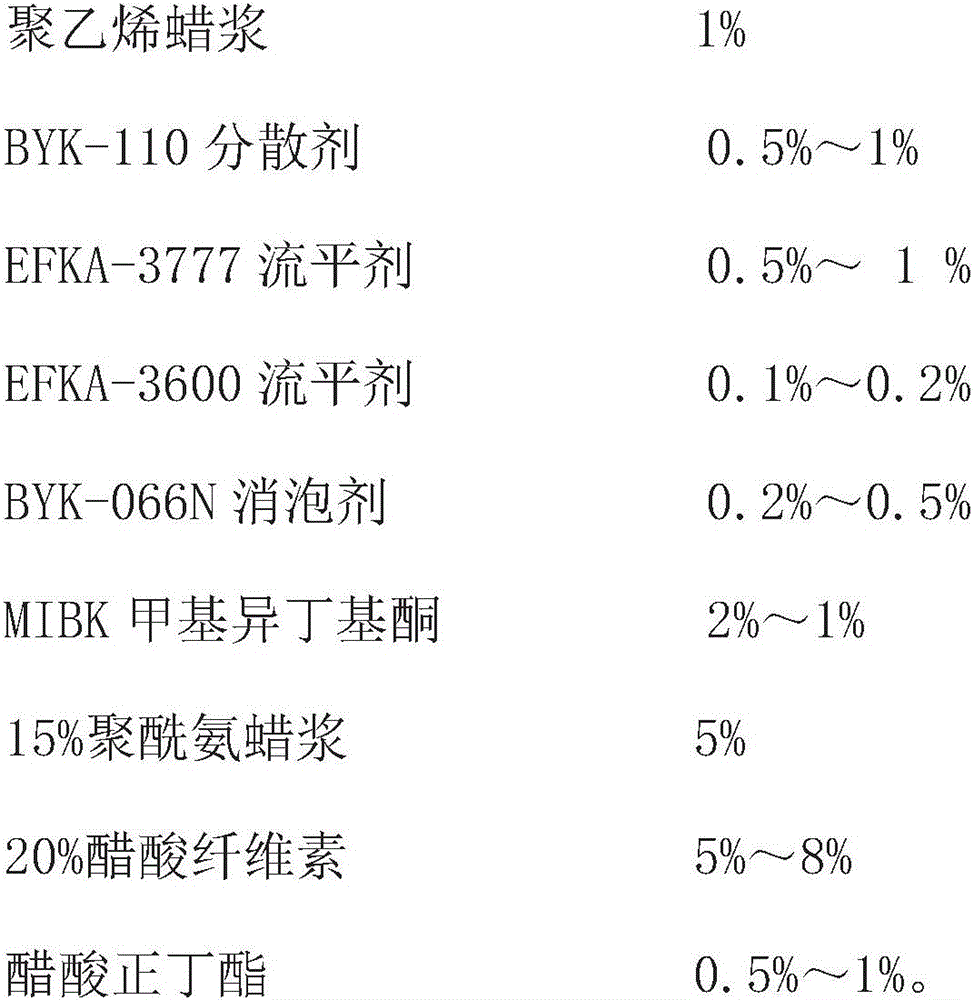

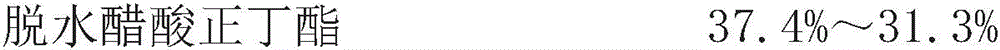

[0030] B. Put in 1272 acrylic resin 41.3%~60%, DP315 saturated polyester resin 25%~40%, polyethylene wax paste 1%, BYK-110 dispersant 0.5%~1%, EFKA-3777 leveling agent 0.5% ~1%, EFKA-3600 leveling agent 0.1%~0.2%, BYK-066N defoamer 0.2%~0.5%, MIBK methyl isobutyl ketone 2%~1%;

[0031] C. Start the disperser and disperse at low speed (1200-1500r / min) for 10 minutes;

[0032] D. Add 5% of 15% polyamide wax slurry, 5% to 8% of 20% cellulose acetate, release no less than 2KG paint at the interface, pour it back into the dispersion tank, and send it for inspection after it is evenly dispersed;

[0033] E. Add 0.5% to 1% of n-butyl acetate to adjust the viscosity to 2500 to 3500mpa.s / 25°C to obtain a transparent base varnish of component A.

[0034] Among them, 1272: High-hydroxyl acrylic resin produced by New Pac...

Embodiment 1

[0057] 1) Preparation of 20% cellulose acetate:

[0058] Methyl ethyl ketone 20Kg

[0059] CAB-551-0.2 20Kg

[0060] Butyl acetate 60Kg

[0061] Disperse and stir until completely dissolved, until the fineness is ≤15um;

[0062] 2) Proportion of component A transparent base varnish:

[0063]

[0064] Uniform dispersion to fineness≤25um, viscosity 2500~3500mpa.s / 25℃

[0065] 3) Proportion of component A magic paint:

[0066] Base paint 80Kg

[0067] Color-changing pearlescent pigment 20Kg

[0068] 4) The ratio of component B:

[0069]

[0070] After dehydration, start stirring and dispersing for 30 minutes, keep warm at 70°C, cool down and discharge and seal.

[0071] HI-100: 100% solid HDI trimer curing agent produced by BASF (China) Co., Ltd.;

[0072] 3390: 90% solid HDI trimer curing agent produced by Bayer;

[0073] 5) The ratio of component C

[0074]

[0075] Stir well and set aside

[0076] The preparation of described component A transparent base v...

Embodiment 2

[0083] 1) Preparation of 20% cellulose acetate:

[0084] Methyl ethyl ketone 20Kg

[0085] CAB-551-0.2 20Kg

[0086] Butyl acetate 60Kg

[0087] Disperse and stir until completely dissolved, until the fineness is ≤15um;

[0088] 2) Proportion of component A transparent base varnish:

[0089]

[0090] Uniform dispersion to fineness≤25um, viscosity 2500~3500mpa.s / 25℃

[0091] 3) Proportion of component A magic paint:

[0092] Base paint 92Kg

[0093] Color-changing pearlescent pigment 8Kg

[0094] 4) The ratio of component B:

[0095]

[0096] After dehydration, start stirring and dispersing for 30 minutes, keep warm at 70°C, cool down and discharge and seal.

[0097] HI-100: 100% solid HDI trimer curing agent produced by BASF (China) Co., Ltd.;

[0098] 3390: 90% solid HDI trimer curing agent produced by Bayer;

[0099] 5) The ratio of component C

[0100]

[0101] Stir well and set aside

[0102] The preparation of described component A transparent base va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com