Fire-resistant polysiloxane composition and application thereof

A technology of polysiloxane and polysiloxane matrix, which is applied in the field of fire-resistant and flame-retardant polysiloxane compositions, and can solve the problem of inability to prevent the spread of fire, inability to perform temperature insulation, heat insulation, fire insulation, and fire protection. and other problems, to achieve the effect of good fire protection, damage prevention, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

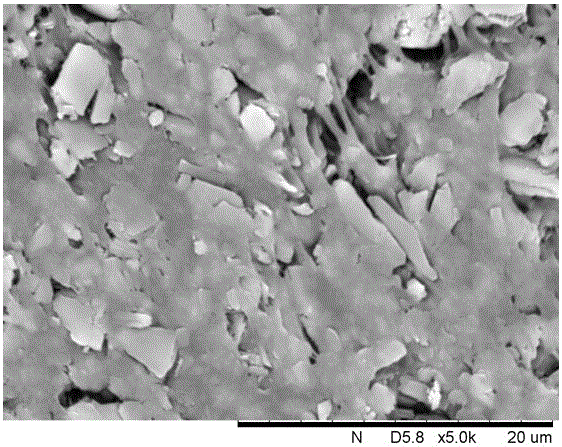

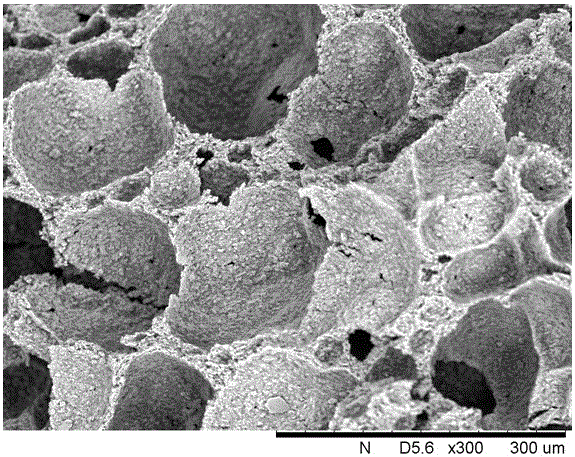

Image

Examples

Embodiment 1-4

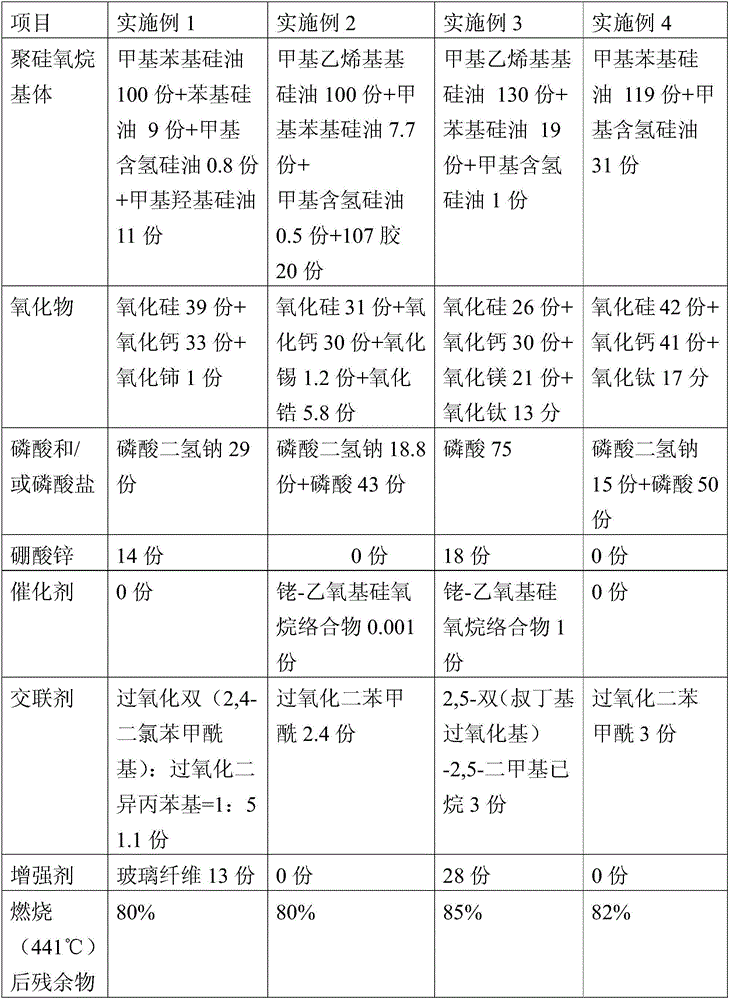

[0029] According to the formula in Table 1, stir the above materials evenly in a star mixer at a temperature of 175°C, add a crosslinking agent after cooling, and extrude to make cables; or, scrape and coat on glass fiber cloth, laminate and heat press into sheets material for making new energy battery cell modules. The test results after combustion of the products prepared in Examples 1-4 are shown in Table 1.

[0030] The fire-proof and fire-resistant cable prepared by the present invention can pass the British fire-resistant cable standard BS6387's 950 ° C × 180 minutes, spray and vibration experiments, can prevent the occurrence of "secondary fire", protect the smooth line of the line in the case of fire, and provide personnel Escape and rescue of property win time.

[0031] The new energy battery cell module prepared by the invention can prevent the fire from spreading when the rechargeable battery is overcharged, and can also play the role of fire blocking, temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com