ABS alloy material capable of solving photocorrosion of plastic part, and preparation method of ABS alloy material

A technology of alloy materials and photocorrosion, which is applied in the field of polymer materials, can solve problems that have not been reported before, achieve the effects of reducing etching strength, improving anti-discoloration ability, and solving photocorrosion phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

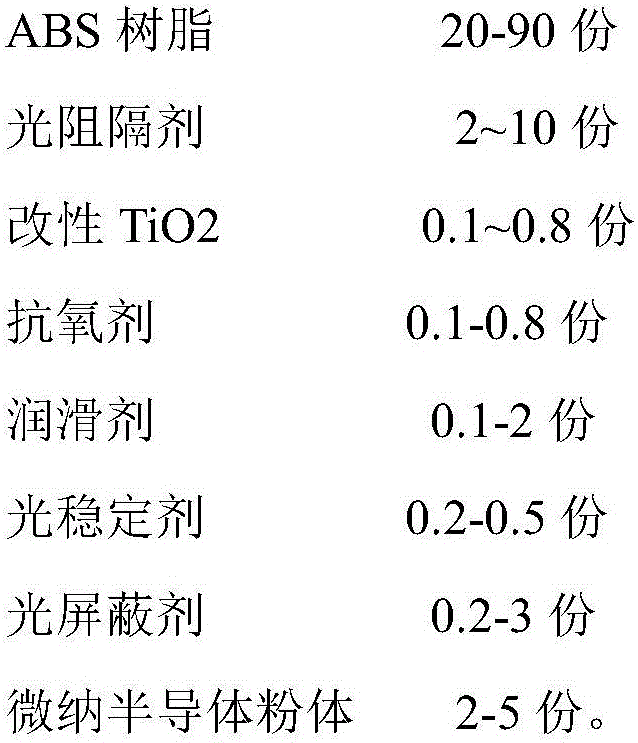

Method used

Image

Examples

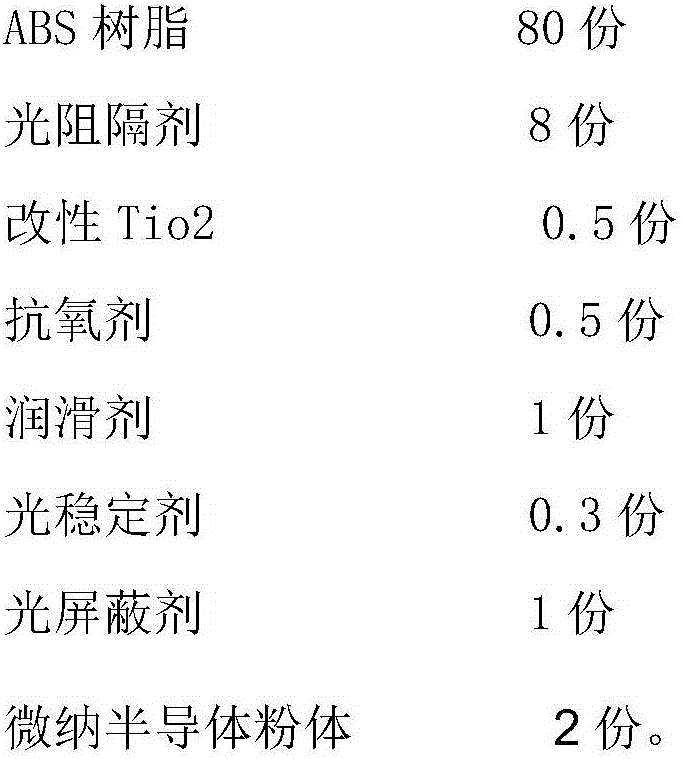

Embodiment 1

[0027]

[0028] The above light blocking agent is superfine talc powder treated with silane coupling agent, and the antioxidant is N, N'-bis[3-(3',5'-di-tert-butyl-4'-hydroxyphenyl)propane Hexamethylene diamide, lubricant is pentaerythritol stearate, light stabilizer is hindered amine HS-944, light shielding agent is carbon black, micro-nano semiconductor powder is a mixture of nano-ZnO and nano-ZnS.

[0029] The preparation method is as follows:

[0030] First, mix the micro-nano semiconductor powder and ABS resin in the mixer, and then add other materials except the light barrier agent and mix them evenly, then add them to the hopper of the twin-screw extruder, and at the same time mix the light barrier agent with It is added in the way of side feeding, melted, blended, extruded, cooled, air-dried, and pelletized to form an ABS alloy material that can solve the photocorrosion of plastic parts.

Embodiment 2

[0051]

[0052] The above-mentioned light blocking agent is barium sulfate surface treated with silane coupling agent, and the antioxidant is N, N'-bis[3-(3',5'-di-tert-butyl-4'-hydroxyphenyl) propionylhexyl Diamine, lubricant is pentaerythritol stearate, light stabilizer is hindered amine HS-944, light shielding agent is carbon black, micro-nano semiconductor powder is a mixture of nano-ZnO and nano-ZnS.

[0053] The preparation method is the same as in Example 1.

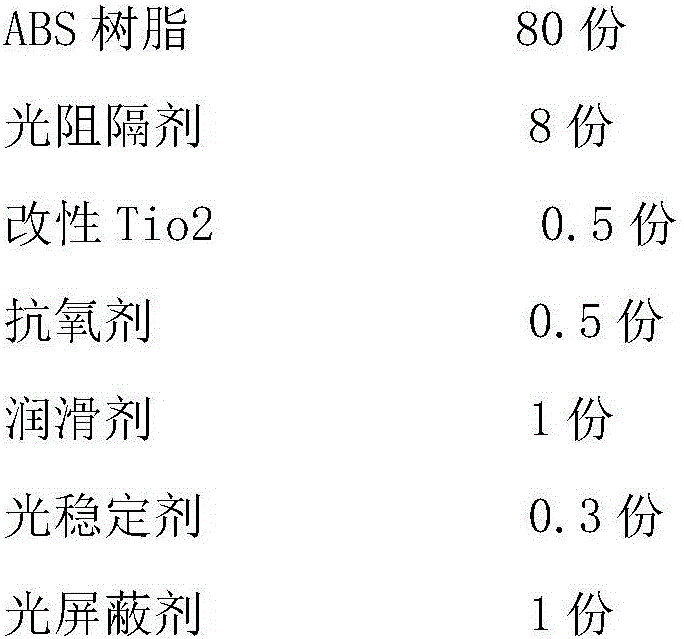

Embodiment 3

[0057]

[0058] The above light blocking agent is superfine talc powder treated with silane coupling agent, and the antioxidant is N, N'-bis[3-(3',5'-di-tert-butyl-4'-hydroxyphenyl)propane Hexamethylene diamide, lubricant is pentaerythritol stearate, light stabilizer is hindered amine HS-944, light shielding agent is carbon black, micro-nano semiconductor powder is a mixture of nano-ZnO and nano-ZnS.

[0059] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com