Mask plate and array substrate

A technology of array substrate and mask plate, which is applied in the direction of optics, instrumentation, photoplate making process of pattern surface, etc., can solve the problem of excessive etching in the via hole area, achieve the effect of reducing the etching intensity and avoiding the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0024] The present invention provides a solution to the problem of excessive etching at the position of the via hole in the prior art.

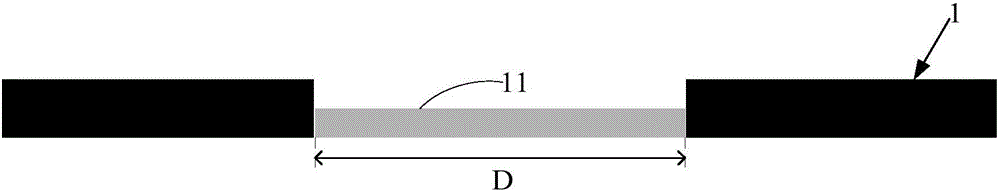

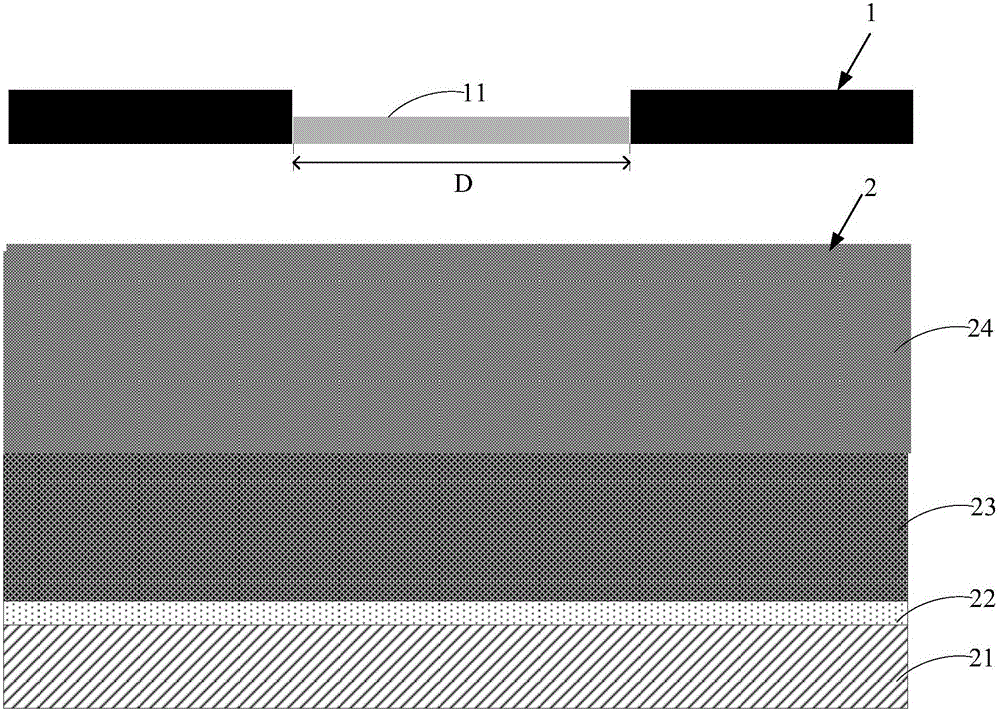

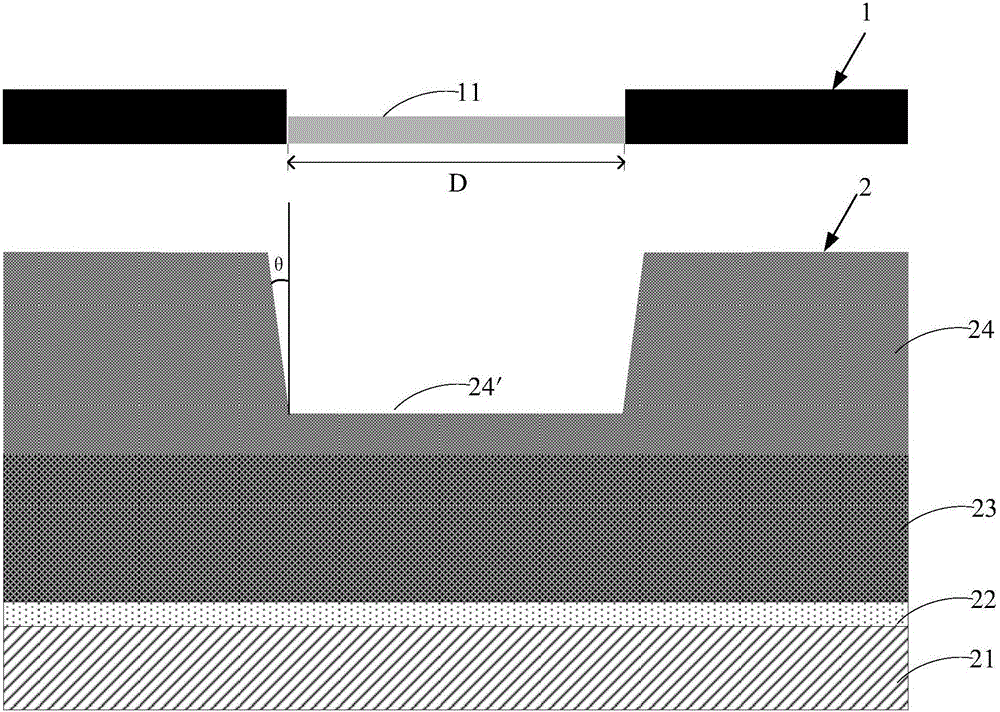

[0025] On the one hand, the embodiment of the present invention provides a mask, which is used to form the pattern of the insulating layer on the array substrate, wherein the insulating layer needs to be formed with via holes, such as figure 1 As shown, the mask plate 1 of this embodiment includes a first region D corresponding to the via hole of the insulating layer, and a semi-transparent pattern 11 is disposed on the first region D.

[0026] further reference Figure 2A , assuming that the mask plate 1 of this embodiment is used to make the via hole of the insulating layer 23 on the array substrate 2, in the specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com