Composite retarder for three-dimensional (3D) house printing paste

A composite retarder, 3D printing technology, applied in the field of building materials, can solve problems such as difficulty in production, and achieve the effects of reducing internal temperature rise, reducing temperature stress, and delaying temperature peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

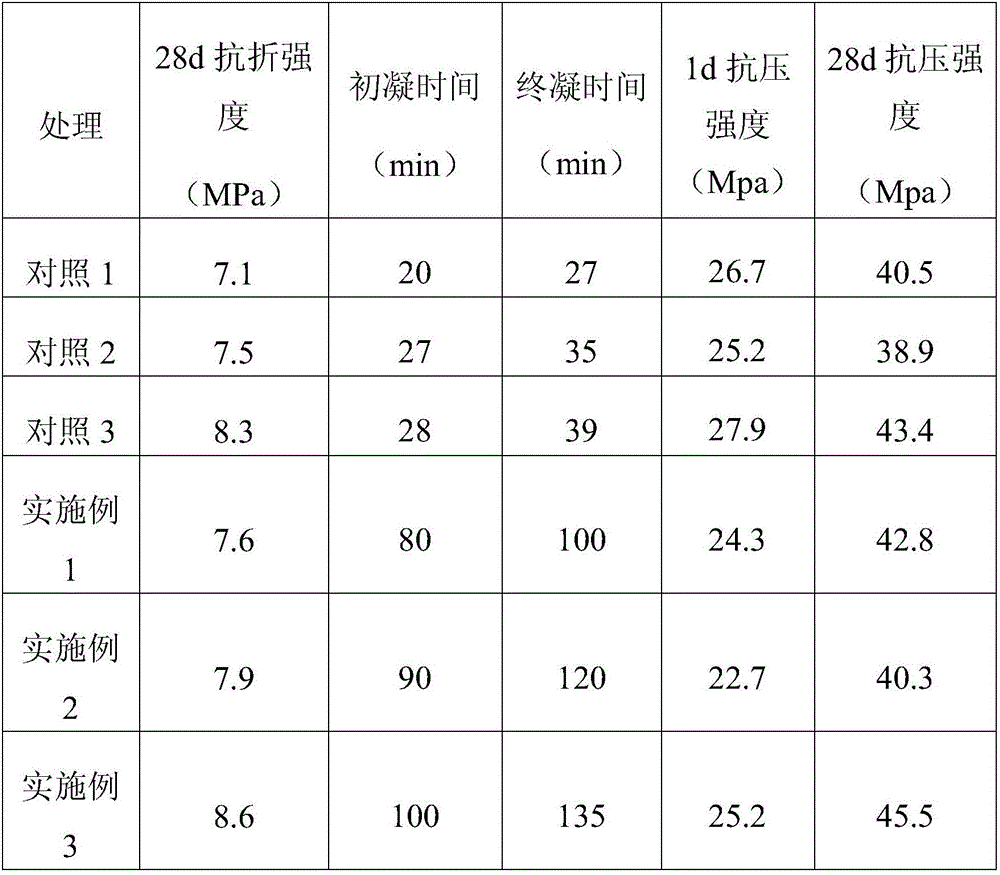

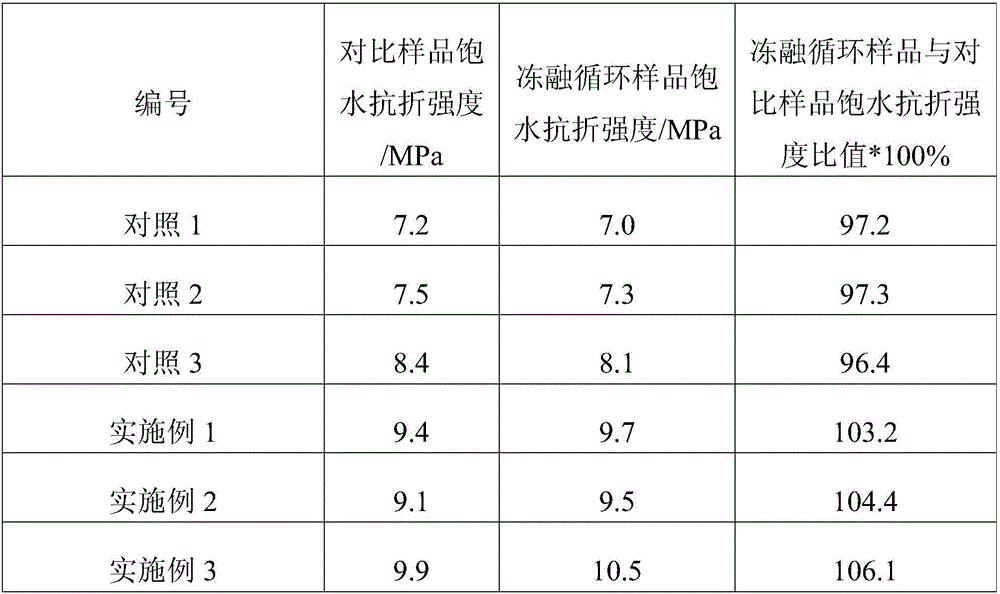

Embodiment 1

[0021] A composite retarder for 3D printing house slurry, which consists of the following raw materials in parts by weight: 15 parts of citric acid, 25 parts of boric acid, 5 parts of quicklime, 5 parts of stearic acid and 10 parts of sodium methylene dinaphthalene sulfonate share.

[0022] The present invention also provides a method for using the composite retarder for 3D printing house slurry, when in use, its mass ratio to the cementitious material is 0.5:100; the cementitious material is quick-hardening sulfur aluminum salt cement.

Embodiment 2

[0024] A composite retarder for 3D printing house slurry, which consists of the following raw materials in parts by weight: 35 parts of citric acid, 45 parts of boric acid, 15 parts of quicklime, 10 parts of stearic acid and 25 parts of sodium methylene dinaphthalene sulfonate share.

[0025] The present invention also provides a method for using the composite retarder for 3D printing house slurry. When in use, its mass ratio to the gelling material is 1.5:100; the gelling material is low-alkalinity sulfur aluminate cement.

Embodiment 3

[0027] A composite retarder for 3D printing house slurry, which consists of the following raw materials in parts by weight: 25 parts of citric acid, 30 parts of boric acid, 10 parts of quicklime, 8 parts of stearic acid and 15 parts of sodium methylene dinaphthalene sulfonate share.

[0028] The present invention also provides a method for using the composite retarder for 3D printing house slurry. When in use, its mass ratio to the gelling material is 1.0:100; the gelling material is high iron sulfoaluminic acid salt cement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com