A control method of optical fiber preform precision stretching numerical control machine tool

A technology for optical fiber preforms and CNC machine tools, which is applied in manufacturing tools and glass manufacturing equipment, etc. It can solve the problems of unstable running speed of the chuck at the right end, non-modifiable control rule table, and difficulty in setting parameters, so as to achieve stable speed and meet control requirements. Requirements, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] In this example, a preform rod with a length of about 1500mm and a diameter of about 48mm is changed to a diameter of 40mm after being stretched. After the stretching operation, the impurities on the optical fiber preform can be removed and prepared for the subsequent drawing operation.

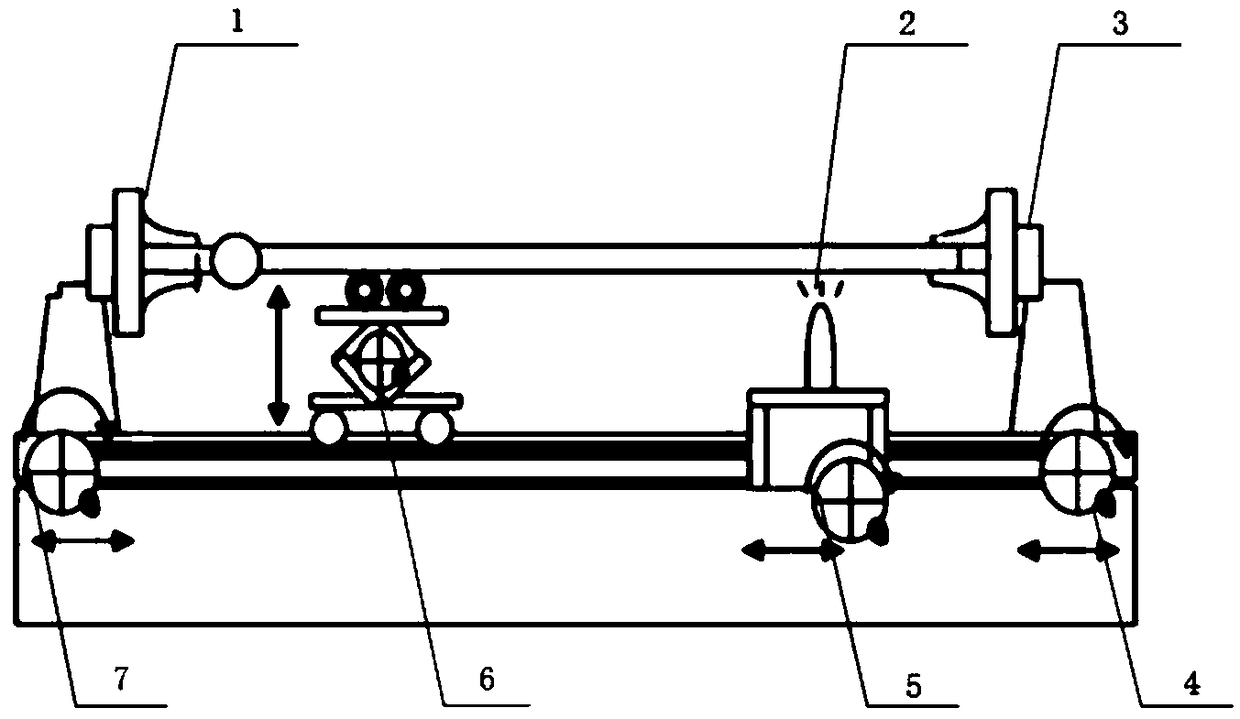

[0036] The optical fiber preform precision extension CNC machine tool is composed of the left end chuck 1, the mobile blowtorch 2, the chuck 3, the diameter measuring instrument, the gas flow controller, the graphite roller 6, and the servo motor. Different from ordinary glass lathes, the positions of the left and right chucks and the moving torch table of this machine can be adjusted through a guide rail behind the bed to ensure the accuracy of the processing position. The maximum distance between the left and right chucks of the machine tool is 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com