Composite material film for photovoltaic module encapsulation and preparation method thereof

A photovoltaic module packaging and composite material film technology, applied in the field of solar photovoltaic, can solve the problems of easy degradation, yellowing, scrapping, reduction of power generation efficiency, etc., and achieve the effect of good anti-PID effect, high economic benefit and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is described in further detail.

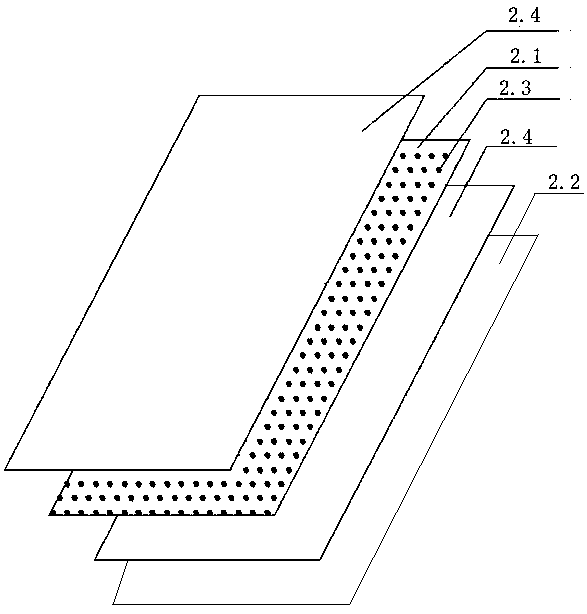

[0018] see figure 1 , the present invention relates to a composite material film used for encapsulation of photovoltaic modules, comprising a polypropylene layer 2.1 and a polyolefin layer 2.2, with pinhole meshes 2.3 evenly opened on the polypropylene layer 2.1, and on the polypropylene layer Both the front and back of 2.1 are sprayed with a layer of TPU thermoplastic polyurethane layer 2.4 Composite the polypropylene layer 2.1 and the polyolefin layer 2.2, because the polyurethane in the polypropylene pinhole mesh 2.3 is like the stakes of the composite layer in series to make the gap between the layers The peel strength is stronger, and the total thickness of the composite film is 70 microns ± 5 microns.

[0019] The preparation method of above-mentioned composite glue film is as follows:

[0020] 1. Use polyurethane that can be well fused with polypropylene and polyolefin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com