CNC (computer numerical control) machine tool

A technology of machine tools and manipulators, applied in the field of machine tools, can solve the problems of operator personal injury, low degree of automation, and high labor costs, and achieve the effect of simplifying the action path, improving the degree of automation, and having a compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A kind of CNC machine tool of the present invention is further described below in conjunction with accompanying drawing:

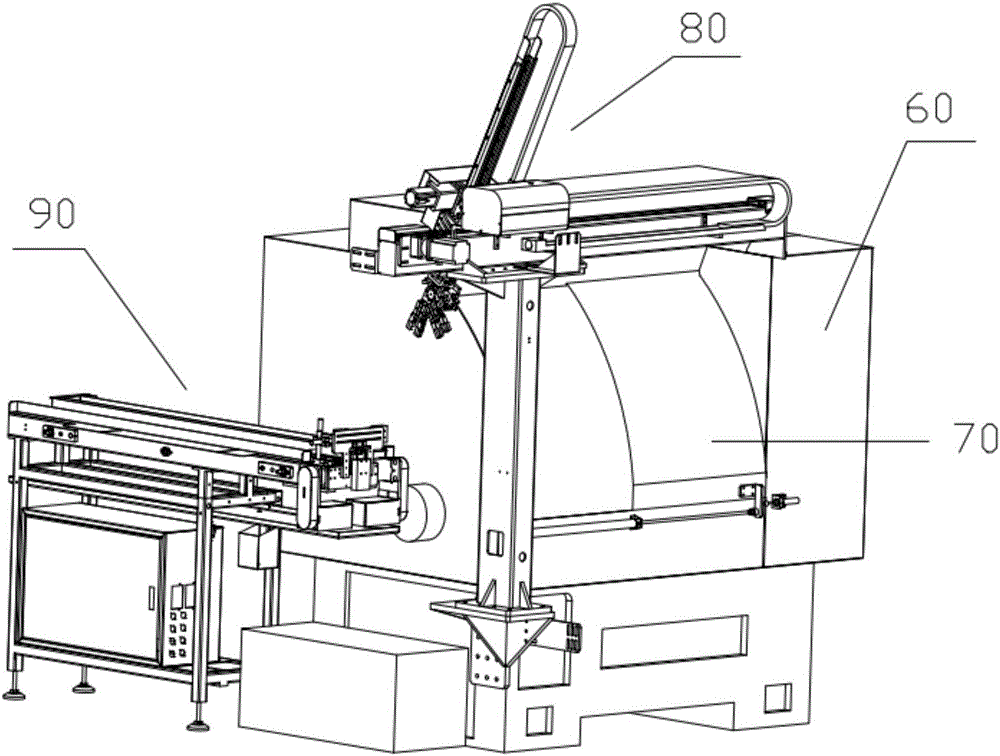

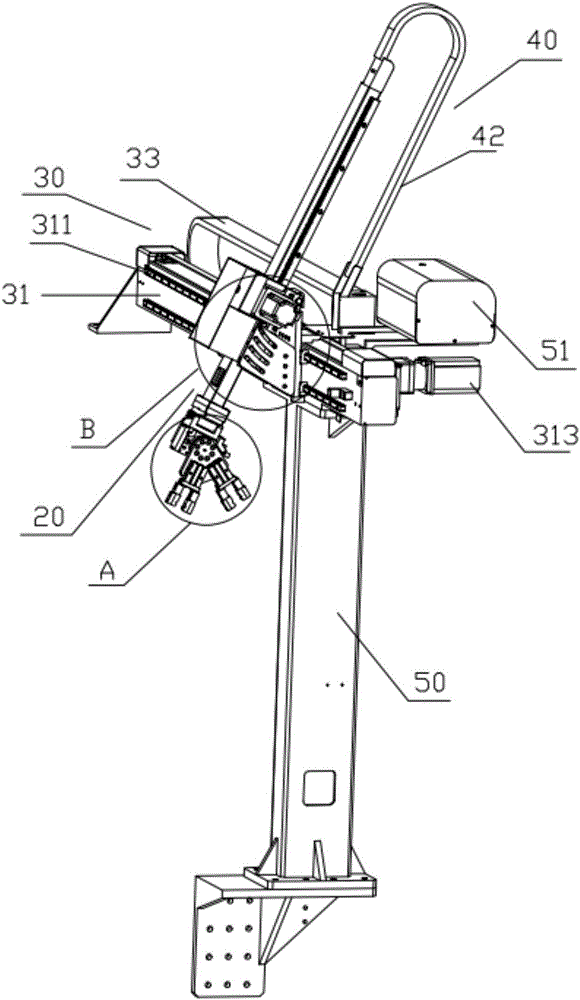

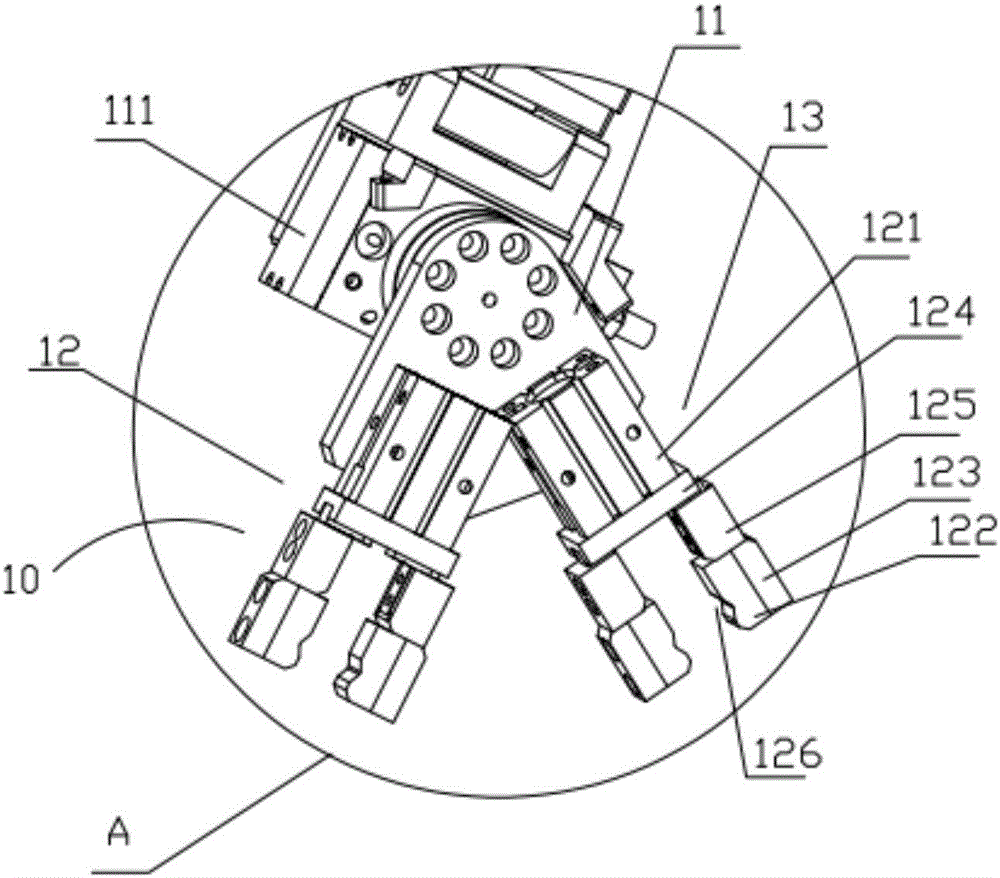

[0028] A kind of CNC lathe, comprises machine tool body 60 and the protective door 70 that is arranged on the machine tool body, also comprises material reclaiming system, and material reclaiming system includes the manipulator device 80 that is arranged on the front of described protective door and is used for feeding and reclaiming and The feed bin 90 for placing and conveying processing parts on one side of the machine tool body 60; the manipulator device 80 includes a manipulator column 50 arranged in front of the protective door 70, a horizontal movement mechanism 30 arranged on the manipulator column 50, Slidingly connected to the lowering mechanism 40 on the horizontal moving mechanism 30, the lowering mechanism 40 can slide left and right on the horizontal moving mechanism 30, and the lowering mechanism 40 is slidably provided with a mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com