Spiral seam lining for improving wear resistance of cyclone or cyclone deduster

A technology of cyclone dust collector and cyclone, which is applied in the direction of the device where the axial direction of the cyclone can be reversed, the cyclone device, etc., can solve the problem of affecting the classification and separation performance and service life of the cyclone or cyclone dust collector, and the cyclone The wear and tear of the dust collector or the cyclone dust collector, the deformation and shedding of the inner lining, etc., achieve the effects of easy replacement of the inner lining, improvement of dust removal efficiency, and improvement of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

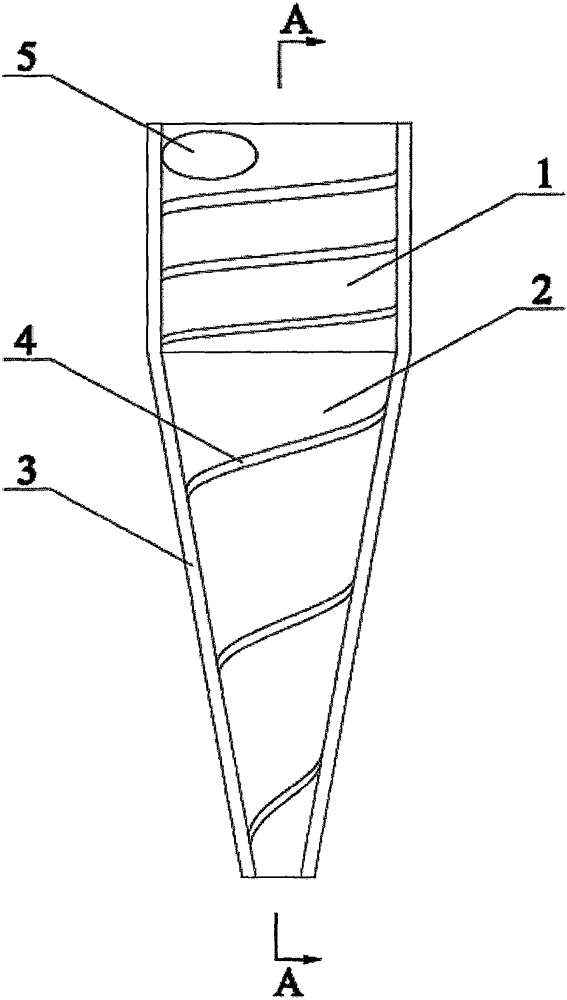

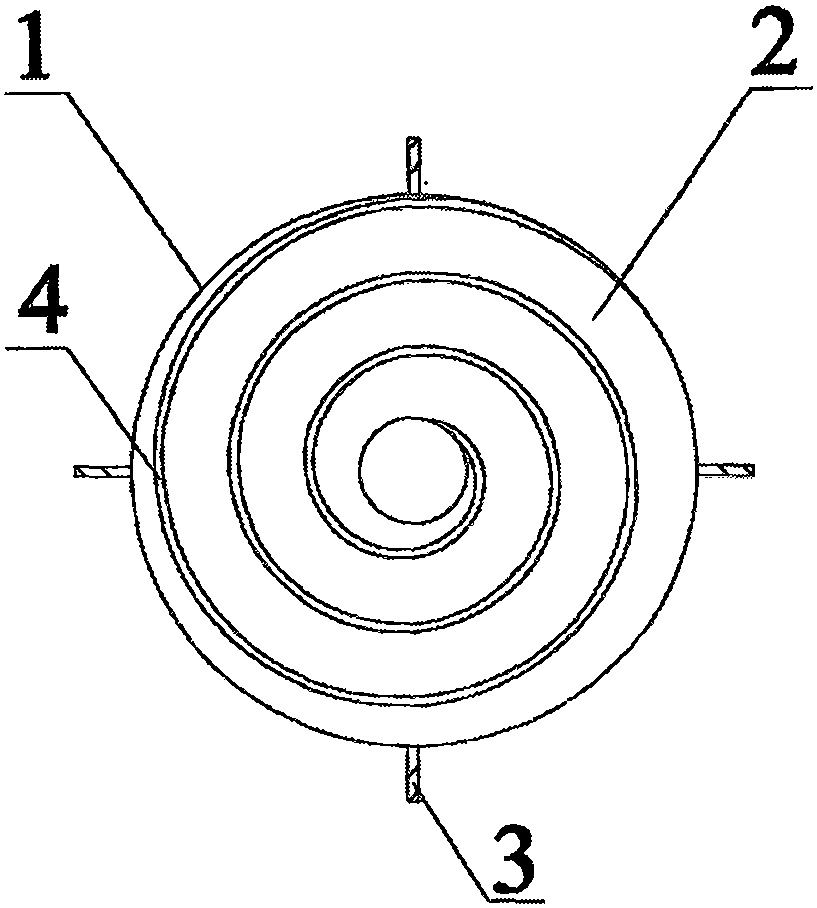

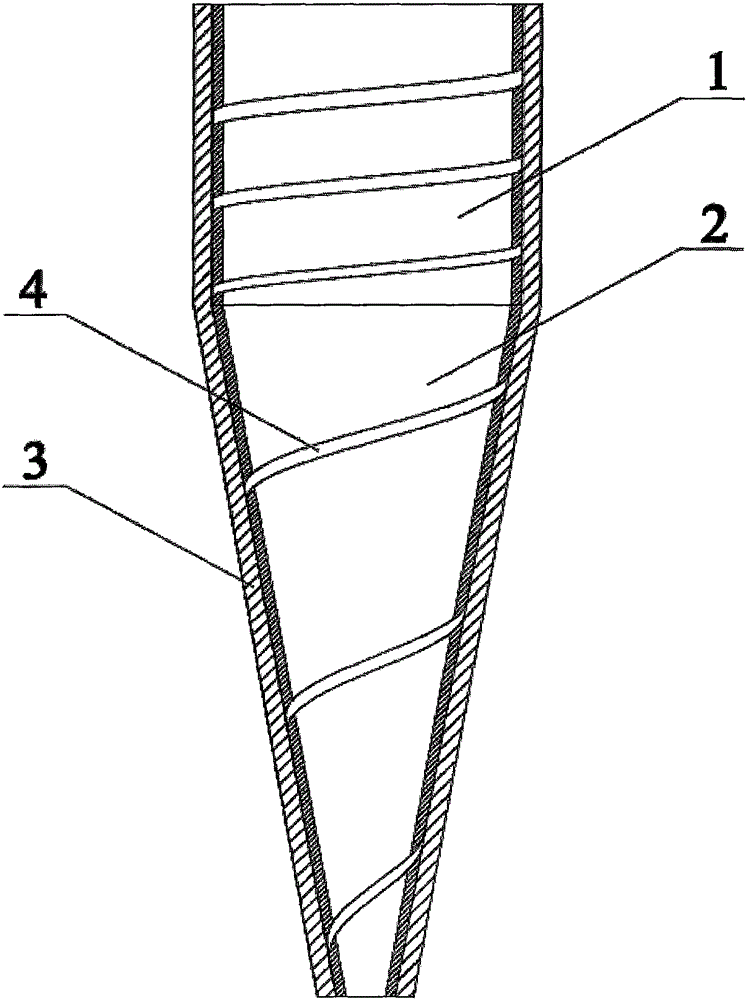

[0024] Embodiment 1: The spiral seam lining for improving the wear resistance of a cyclone or a cyclone dust collector includes a cylindrical body 1 , a cone 2 , ribs 3 , spiral seams 4 , and an oval inlet 5 . like Figure 4 As shown, in this embodiment, the spiral seam lining is used in the cyclone, and the spiral seam is provided on the lining, and the width of the spiral seam is 5-40mm. The distance between the spiral seam lining and the vessel wall is generally 5-40mm, that is, the width of the ribs welded on the outer wall of the spiral seam lining is 5-40mm, and the ribs are welded vertically on the outer wall of the cylinder and the cone to form a whole , the thickness of the ribs is 2-10mm, and the number is 3-5 pieces, which are evenly distributed. The diameter of the cylinder and cone of the inner lining is 10-80mm smaller than that of the cyclone or cyclone dust collector, that is, twice the width of the welded ribs on the outer wall, and the height is the same as ...

Embodiment 2

[0027] Embodiment 2: This is used to improve the spiral seam lining of cyclone or cyclone dust collector wear resistance such as figure 1 , figure 2 , image 3 shown. Its structure is the same as that of Embodiment 1 except that relevant parameters are different. In this embodiment, the spiral seam lining is used for the cyclone dust collector, such as Figure 5 Shown is the structure diagram of the cyclone dust collector after adding the spiral seam lining. In this embodiment, the width of the spiral seam is 10 mm, and the thickness of the ribs welded on the outer wall of the spiral seam lining is 3 mm, the width is 10 mm, the number of ribs is 4, and the ribs are vertically welded on the outer wall of the inner lining of the spiral seam , evenly welded in the four positions of the spiral seam lining, front, back, left and right. In this embodiment, the diameter of the cylindrical cylinder of the cyclone dust collector is 380 mm, and the cone angle is 20°, so the intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com