Low loading palladium platinum core-shell structure catalyst and its preparation method and application

A core-shell structure, low-load technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high metal loading, cumbersome operation, complete oxidation The problem of high temperature can achieve the effect of low environmental cost, easy availability of raw materials and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Will Pd 2 (dba) 3 (0.22g, 2.4×10 -4 mol) was added into PC (100mL), under 3MPa hydrogen environment and room temperature, stirred and reacted for 2h to obtain a solution containing Pd nanoparticles, Al 2 o 3 Carrier (100g) was added to the obtained solution containing Pd nanoparticles, stirred for 12h, filtered with suction, and the filter cake was vacuum-dried at 100°C for 5h to obtain Pd / Al 2 o 3 Catalyst 100g.

[0026] The loading amount of metal Pd in the obtained catalyst was 0.03wt%.

Embodiment 2

[0028] H 2 PtCl 6 ·6H 2 O (0.13g, 2.5×10 -4 mol) was added to PC (100mL), under 3MPa hydrogen environment and room temperature, stirred and reacted for 2h to obtain a solution containing Pt nanoparticles, Al 2 o 3 Carrier (100g) was added to the obtained solution containing Pd nanoparticles, stirred for 12h, filtered with suction, and the filter cake was vacuum-dried at 100°C for 5h to obtain Pt / Al 2 o 3 Catalyst 100g.

[0029] The loading amount of metal Pt in the obtained catalyst was 0.03wt%.

Embodiment 3

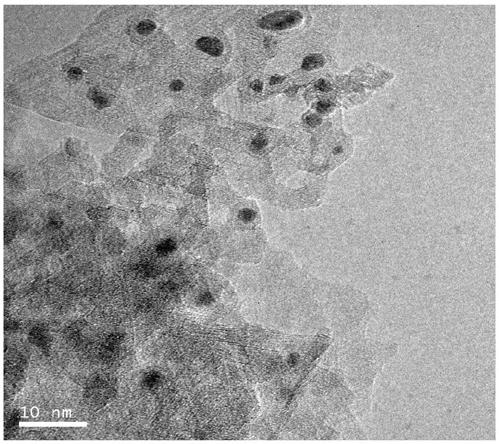

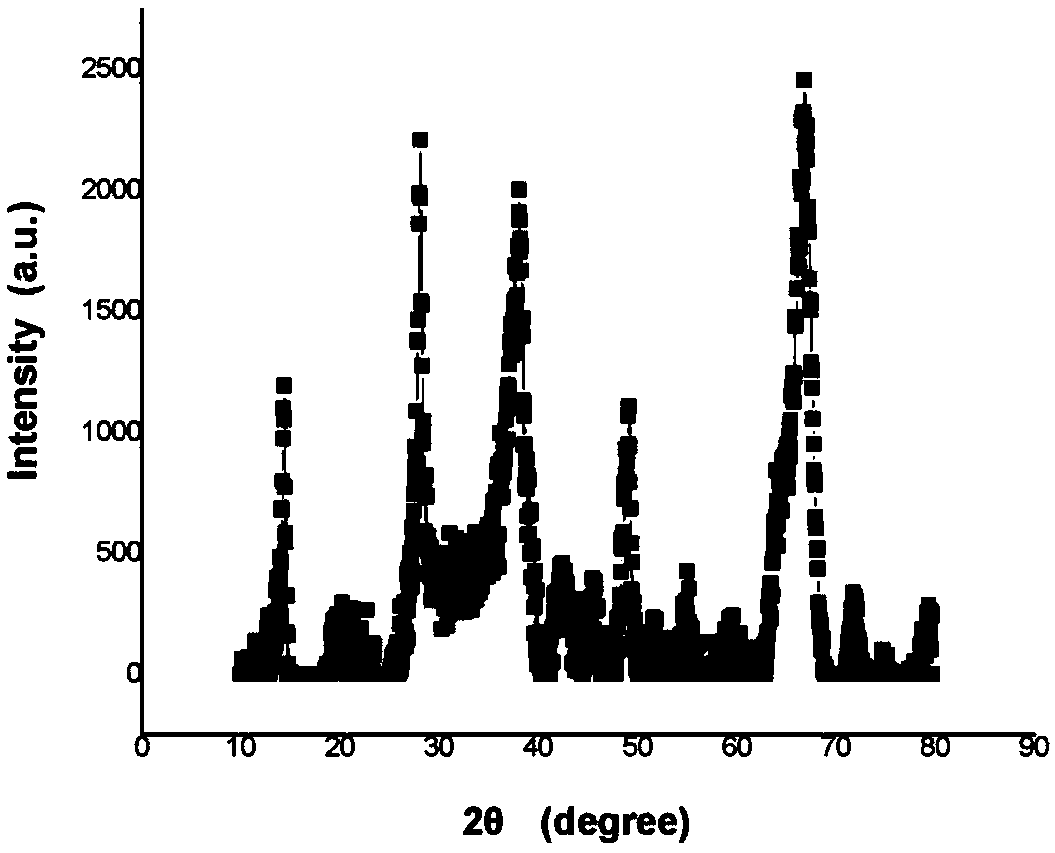

[0031] Will Pd 2 (dba) 3 (0.023g, 2.5×10 -5 mol) mixed with propylene carbonate (100mL), under 3MPa hydrogen atmosphere and room temperature, stirred for 2h to obtain a solution containing Pd nanoparticles; 2 PtCl 6 ·6H 2 O (0.027g, 5.2×10 -5 mol) was added to the obtained solution containing Pd nanoparticles, and stirred and reacted for 2 hours under 3MPa hydrogen atmosphere and room temperature to obtain a solution containing the active component of the core-shell structure; the solution and the carrier Al2 o 3 (100g) mixed, stirred for 12h, suction filtered, and the filter cake was vacuum-dried (100°C, dried for 5h) to obtain Pd@Pt / Al 2 o 3 Catalyst 100g.

[0032] The total loading of metals Pd and Pt in the obtained catalyst was 0.03 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com