Lignin nano-particles with high ultraviolet protection performance and preparation method of lignin nano-particle

A technology of nanoparticles and protection performance, which is applied in the field of lignin nanoparticles with high UV protection performance and its preparation. It can solve the problems of weakening the UV absorption performance of lignin, which is not conducive to human health, and sacrificing anti-oxidation performance, and achieves excellent UV protection performance. Good protection performance, good UV protection performance, green and environmental protection effect in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037](1) Put 0.01g of solvent-based lignin in a 1000mL beaker, add 100mL of acetone / water mixture (the volume ratio of acetone to water is 4:1), stir and dissolve at room temperature to obtain a 0.1g / L lignin solution .

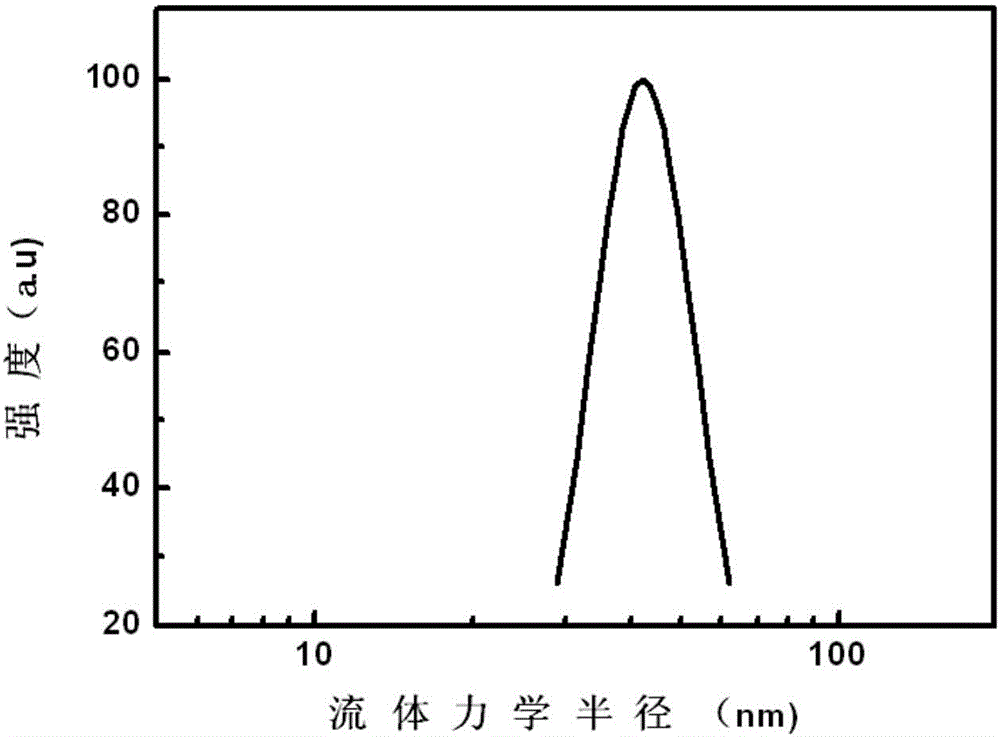

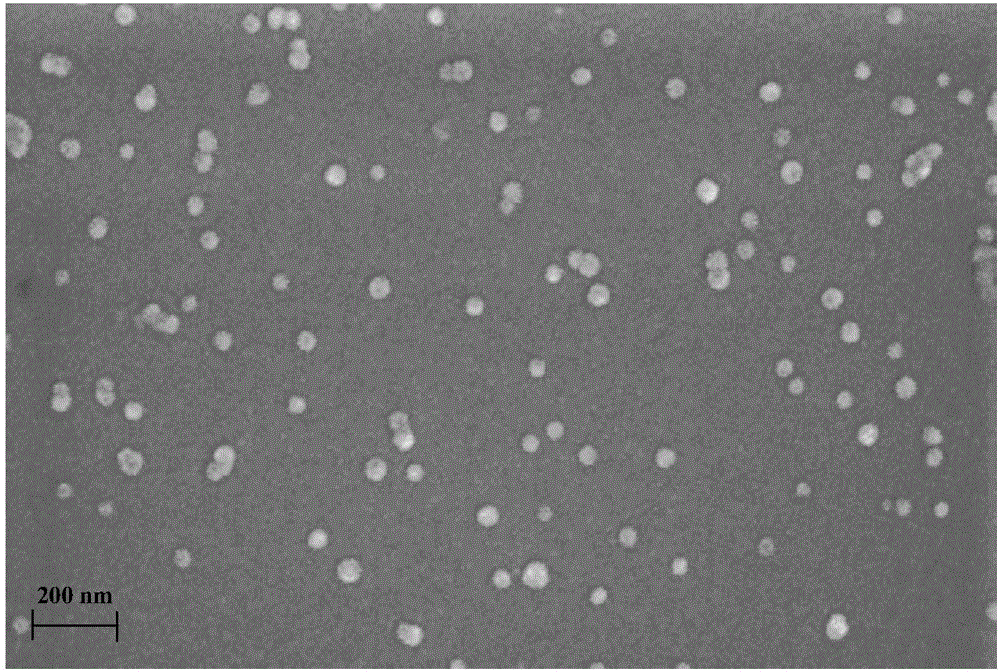

[0038] (2) Slowly add 300 mL of water to the lignin solution obtained in step (1), stir under normal temperature and pressure to form spherical micelles, and obtain a suspension containing small-sized lignin nanoparticles. The suspension was rotary evaporated and then dried to obtain small-sized lignin nanoparticles. figure 1 It is a scanning electron microscope picture of the small-sized lignin nano-particles of the product of this example taken by a Nova NanoSEM 430 scanning electron microscope in the Netherlands, showing that the particles are solid spherical structures with a diameter of about 50 nm. figure 2 It is the particle size distribution diagram of the small-sized lignin nanoparticles of the product of this embodiment measured by the German ALV...

Embodiment 2

[0044] (1) Put 1 g of solvent-based lignin in a 1000 mL beaker, add 100 mL of acetone / water mixture (the volume ratio of acetone to water is 4:1), stir and dissolve at room temperature to obtain a 10 g / L lignin solution.

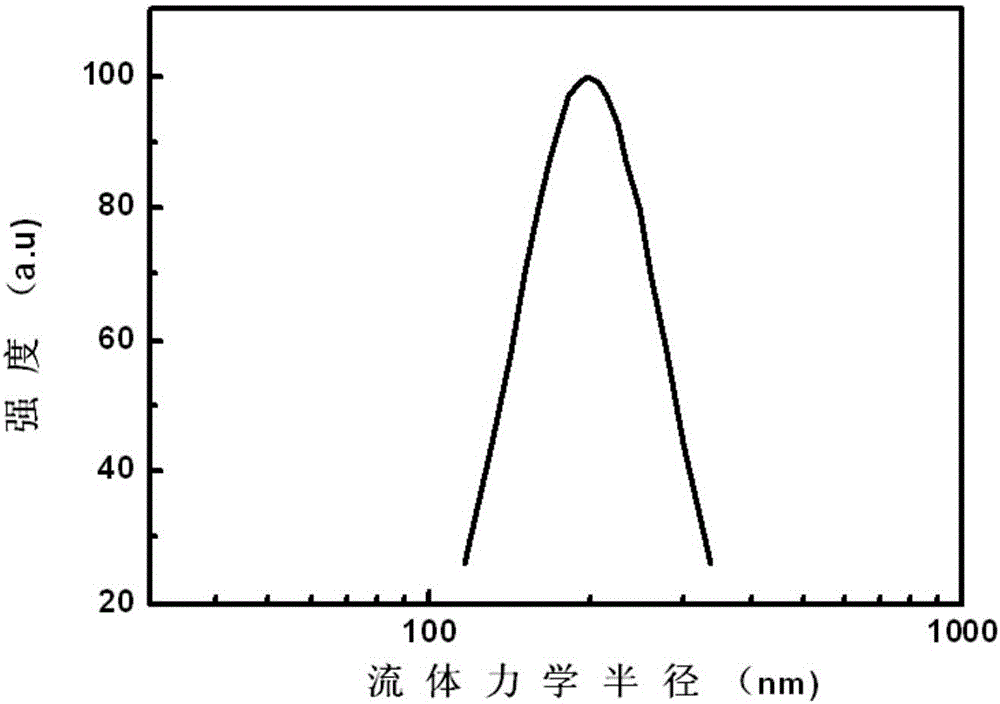

[0045] (2) Slowly add 300 mL of water to the lignin solution obtained in step (1), stir at normal temperature and pressure to form spherical micelles, and obtain a suspension containing medium-sized lignin nanoparticles. The suspension was rotary evaporated and then dried to obtain medium-sized lignin nanoparticles. The particle size distribution and surface morphology of the lignin nanoparticles are tested by the same light scattering and scanning electron microscope test method as in Example 1, which shows that the hydrodynamic radius of the gained nanoparticles is 100-300nm, such as image 3 , Figure 4 shown.

[0046] Mix the product of this example with a blank cream that has no sunscreen effect at a mass fraction of 5% and 10%, and at the same time c...

Embodiment 3

[0051] (1) Put 0.03g of enzymatic lignin in a 1000mL beaker, add 100mL of acetone / water mixture (the volume ratio of acetone to water is 5:1), stir and dissolve at room temperature to obtain a 0.3g / L lignin solution .

[0052] (2) Slowly add 300 mL of water to the lignin solution obtained in step (1), stir under normal temperature and pressure to form spherical micelles, and obtain a suspension containing small-sized lignin nanoparticles. The suspension was rotary evaporated and then freeze-dried to obtain small-sized lignin nanoparticles. The morphology and particle size distribution of the lignin nanoparticles were tested using the same scanning electron microscope and light scattering as in Example 1, which showed that the hydrodynamic radius of the obtained nanoparticles was 35-75 nm. respectively with figure 1 , figure 2 basically the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com