Method for improving base material of saline-alkali soil by utilizing aquaculture sludge

A saline-alkali soil improvement and aquaculture technology, which is applied in the field of aquaculture sludge, can solve the problems of aquaculture impact, aquaculture sludge is difficult to handle, etc., and achieve the effects of easy decomposition, accelerated drainage and salt discharge, and increased soil organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

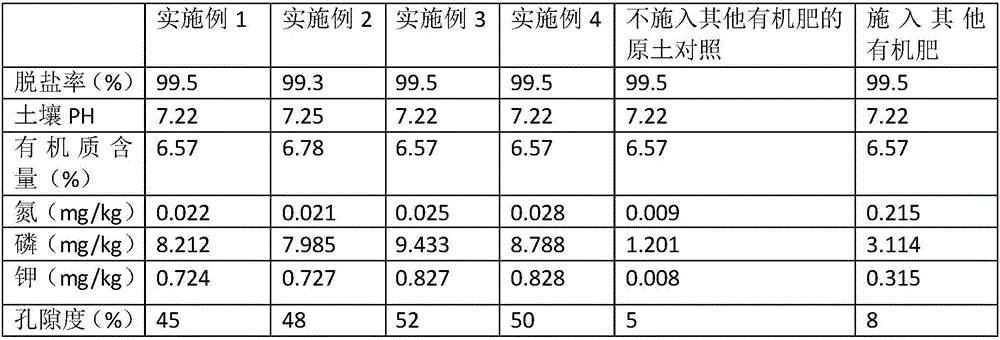

Examples

Embodiment 1

[0023] A kind of method that aquaculture sludge is used for saline-alkali soil improvement substrate, it comprises the following steps:

[0024] S1. Prepare aquaculture sludge mixture according to the following formula weight parts: 50 parts of aquaculture sludge, 20 parts of tea residue, 8 parts of polymaleic anhydride, 18 parts of dead leaves, 4 parts of calcium-based bentonite, 20 parts of vermicompost Wherein, in the described aquaculture sludge, by mass percent, nitrogen 13%, phosphorus 17%, potassium 13%, humus 22%, potassium bacteria 0.05%, phosphorus bacteria 0.05%, actinomycetes 0.07% , the balance being sludge; the dead leaves include a mixture of the yellow fallen leaves and old decayed leaves of trees; the tea residues are oolong tea and black tea;

[0025] S2. Leveling the saline-alkali land, then plowing 40 to 60 centimeters deep, and then watering;

[0026] S3, use wind-blown sandy soil to spread evenly on the soil surface of the initial leveling and plowing, t...

Embodiment 2

[0029] A kind of method that aquaculture sludge is used for saline-alkali soil improvement substrate, it comprises the following steps:

[0030] S1. Prepare the aquaculture sludge mixture according to the following formula in parts by weight: 80 parts of aquaculture sludge, 10 parts of tea leaves, 10 parts of polymaleic anhydride, 14 parts of dead leaves, 8 parts of calcium-based bentonite, and 10 parts of vermicompost Wherein, in the described aquaculture sludge, by mass percentage, nitrogen 15%, phosphorus 14%, potassium 18%, humus 20%, potassium bacteria 0.05%, phosphorus bacteria 0.05%, actinomycetes 0.07% , the balance being sludge; the dead leaves include a mixture of pine needles and coconut chaff residues; the tea leaves are a mixture of white tea, green tea and black tea;

[0031] S2. Leveling the saline-alkali land, then plowing 40 to 60 centimeters deep, and then watering;

[0032] S3, use wind-blown sandy soil to spread evenly on the soil surface of the initial le...

Embodiment 3

[0035] A kind of method that aquaculture sludge is used for saline-alkali soil improvement substrate, it comprises the following steps:

[0036] S1. Prepare aquaculture sludge mixture according to the following formula weight parts: 50 parts of aquaculture sludge, 20 parts of tea residue, 8 parts of polymaleic anhydride, 18 parts of dead leaves, 4 parts of calcium-based bentonite, 20 parts of vermicompost Wherein, in the described aquaculture sludge, by mass percent, nitrogen 13%, phosphorus 17%, potassium 13%, humus 22%, potassium bacteria 0.05%, phosphorus bacteria 0.05%, actinomycetes 0.07% , the balance is sludge; the dead leaves include a mixture of the yellow fallen leaves, pine needles and coconut bran residue materials of the trees; the tea residue is a mixture of oolong tea and yellow tea;

[0037] S2. Leveling the saline-alkali land, then plowing 40 to 60 centimeters deep, and then watering;

[0038] S3, use wind-blown sandy soil to spread evenly on the soil surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com