Method for improving drought resistance of plant growing on tail slag

A tailings slag and drought-resistant technology, applied in the field of ecological restoration materials, can solve problems such as weak water holding capacity, affecting plant growth and seedling survival, and affecting plant fixation and restoration efficiency, achieving slow decay and decomposition, promoting vegetation reconstruction and fixing substrates, The effect of reducing soil erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

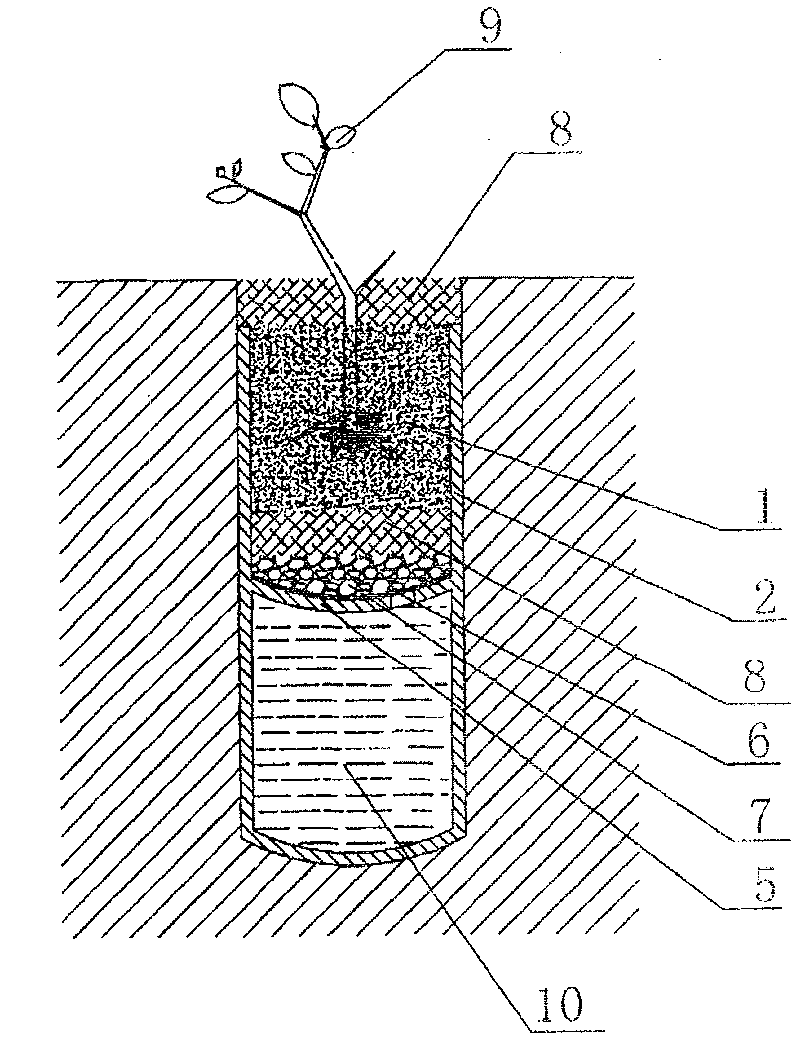

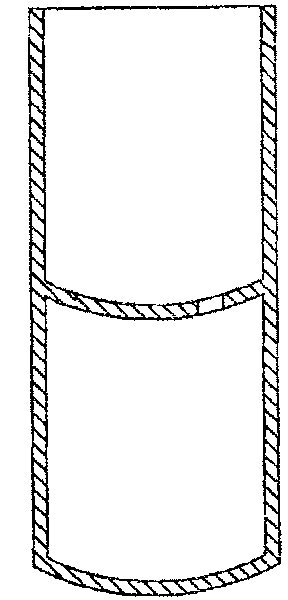

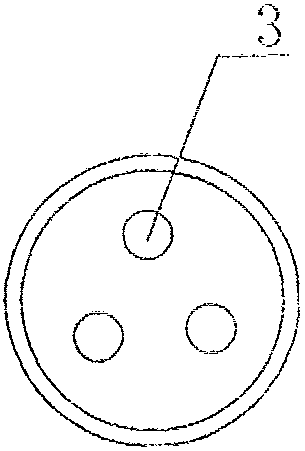

[0026] From March 2006 to December 2007, a field test was carried out in the decommissioned uranium tailings reservoir area of Hengyang 272 Plant. The selected plant is Trema dielsiana, figure 1 , 2 , 3, 4, bamboo tube 2 diameters are 17cm, two joints in total, and total length is 51cm, and bamboo tube 2 one ends keep intersection spacer, as bottom; The other end saws off nodal spacer, as top. Three apertures 3 are drilled on the interlayer 5 between the two joints, and porous plastic gauze 6 is arranged on this interlayer by top side paving, prevents aperture from clogging, and favorable water circulation. There is no small opening on the side of the joint at the bottom, and it is filled with water 10. In order to facilitate the growth and distribution of plant roots, four small openings 4 with a size of 1.2cm×2cm are opened from top to bottom on the side of the top section of the bamboo tube. The thick river sand 7 of broad bean size 3.5cm is laid on the perforated plas...

Embodiment 2

[0028] From March 2006 to December 2007, a field test was carried out in the decommissioned uranium tailings reservoir area of Hengyang 272 Plant. The selected plant was Pokeweed (Phytolacca americana), figure 1 , 2 , 3, 4, bamboo tube 2 diameters 8cm, two joints in total, total length 40cm, one end retains the joint interval layer, as the bottom; the other end saws off the joint interval layer, as the top. Three apertures 3 are drilled on the interlayer 5 between the two joints, and porous plastic gauze 6 is arranged on this interlayer 5 by top side paving, prevents aperture from clogging, and facilitates water circulation. There is no small opening on the side of the joint at the bottom, and it is filled with water 10. In order to facilitate the growth and distribution of plant roots, three small openings 4 of 1.2cm×2cm are opened from top to bottom on the side of the top section of the bamboo tube. On the perforated plastic gauze 6 that is paved on the top of the bambo...

Embodiment 3

[0030] From March 2006 to December 2007, a field test was carried out in the decommissioned uranium tailings reservoir area of Hengyang 272 Plant. The selected plants were Pokeweed, figure 1 , 2, 3, 4, bamboo tube 2 diameters 12cm, two joints in total, total length 50cm, one end retains the intersection spacer layer, as the bottom end; The other end saws off the joint spacer layer, as the top. Three apertures 3 are drilled on the interlayer 5 between the two joints, and porous plastic gauze 6 is arranged on this interlayer 5 by top side paving, prevents aperture from clogging, and facilitates water circulation. There is no small opening on the side of the joint at the bottom, and it is filled with water 10. In order to facilitate the growth and distribution of plant roots, four small openings 4 of 1.2cm×2cm are opened from top to bottom on the side of the top section of the bamboo tube. On the perforated plastic gauze 6 that is paved on the top of the bamboo tube, pave th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com