Water retaining SAP (Super Absorbent Polymer)-mixed soil prepared by using biogass fermentative residues and preparation method thereof

A biogas fermentation and residue technology, applied in chemical instruments and methods, fertilizer mixtures, soil conditioning materials, etc., can solve environmental hazards and other problems, and achieve the effects of promoting plant growth, reducing the temperature difference between day and night, and increasing ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Mix 3.5kg of biogas residue, 1.8kg of sawdust, 0.55kg of bone meal, and 4kg of soil, and crush them until the particle size is less than 3mm. Dry matter, then take 0.15 kg of starch-grafted acrylic acid type water-retaining agent to be swollen, add it to the mixture, then add 3000 mL of biogas slurry and stir evenly, and place it in normal temperature for 20 days after anaerobic fermentation to obtain a water-retaining mixture prepared from biogas fermentation residue earth.

[0030] The mass percentage of each component in the obtained water-retaining mixed agent soil is as follows: 35% biogas residue, 18% sawdust, 5.5% bone meal, 40% soil, 1.5% starch-grafted acrylic water-retaining agent, and 3000mL biogas slurry.

Embodiment 2

[0032] Mix 3.5kg of biogas residue, 1.8kg of sawdust, 0.55kg of bone meal, and 4kg of soil, and crush until the particle size is less than 3mm. The biogas residue is the solid-phase air-dried residue of biogas fermentation of human and animal manure that has produced gas for more than 60 days, and then Take 0.15 kg of starch-grafted acrylic acid-type water-retaining agent and add it to the mixture after swelling, then add 3000 mL of biogas slurry and stir evenly. After 30 days of anaerobic fermentation at room temperature, a water-retaining mixture soil prepared from biogas fermentation residues is obtained.

[0033] The mass percentage of each component in the obtained water-retaining mixed agent soil is as follows: 35% biogas residue, 18% sawdust, 5.5% bone meal, 40% soil, 1.5% starch-grafted acrylic water-retaining agent, and 3000mL biogas slurry.

Embodiment 3

[0035] Mix 3.5kg of biogas residue, 1.8kg of sawdust, 0.55kg of bone meal, and 4kg of soil, and crush until the particle size is less than 3mm. The biogas residue is the solid-phase air-dried residue of biogas fermentation of crop straw that has produced gas for more than 60 days, and then Take 0.15 kg of starch-grafted acrylic acid type water-retaining agent and add it to the mixture after swelling, then add 3000 mL of biogas slurry and stir evenly, and place it in room temperature for anaerobic fermentation for 25 days to obtain a water-retaining mixture soil prepared from biogas fermentation residues.

[0036] The mass percentage of each component in the obtained water-retaining mixed agent soil is as follows: 35% biogas residue, 18% sawdust, 5.5% bone meal, 40% soil, 1.5% starch-grafted acrylic water-retaining agent, and 3000mL biogas slurry.

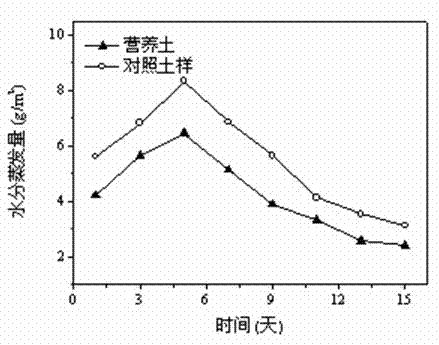

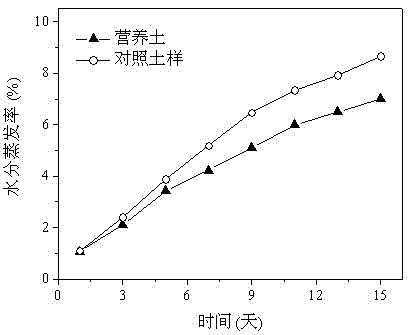

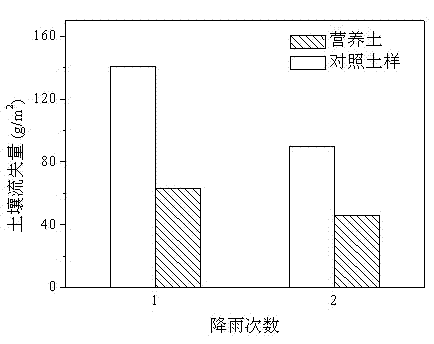

[0037] The compound fertilizer-preserving mixed agent soil that adopts embodiment 1 gained carries out physical and chemical charac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com