Automatic impedance matching ultrasonic circuit driver and automatic dynamic matching method thereof

An automatic impedance and impedance dynamic technology, applied in electrical components, generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem of affecting the performance and stability of ultrasonic systems and reduce system energy rotation. Efficiency, performance improvement bottlenecks, etc., to achieve the effect of improving energy conversion efficiency, fast phase switching, and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

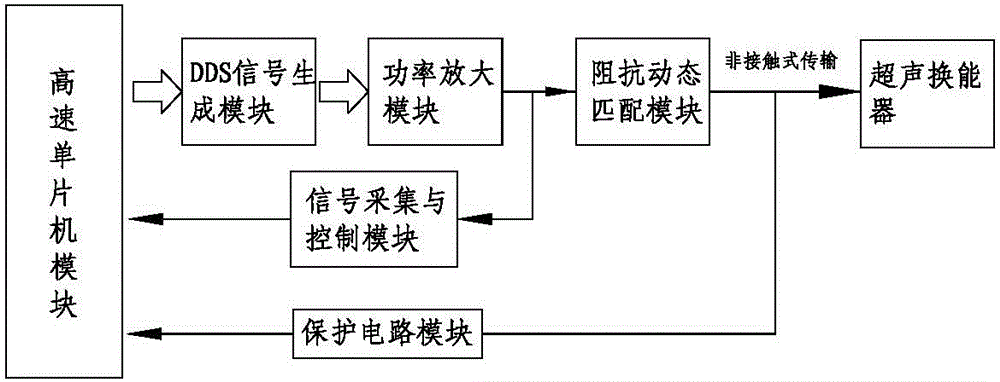

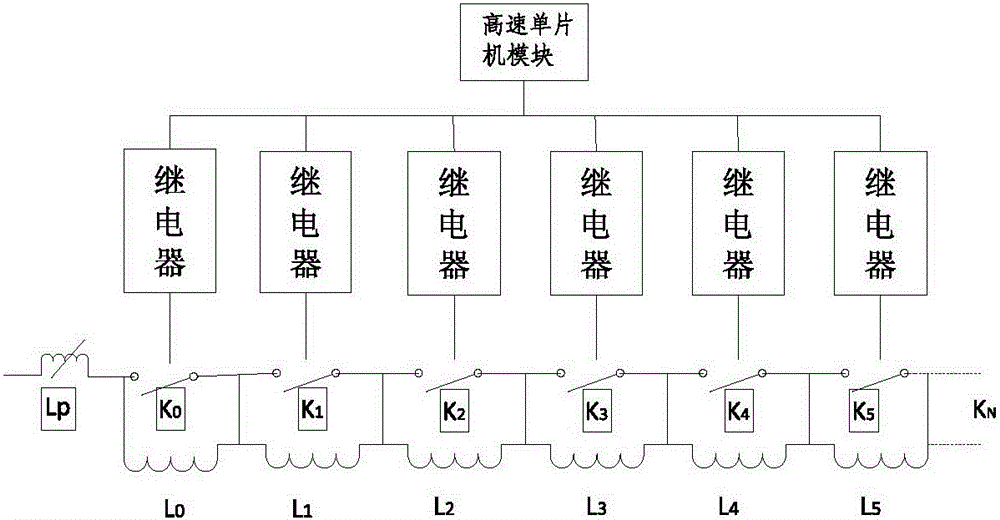

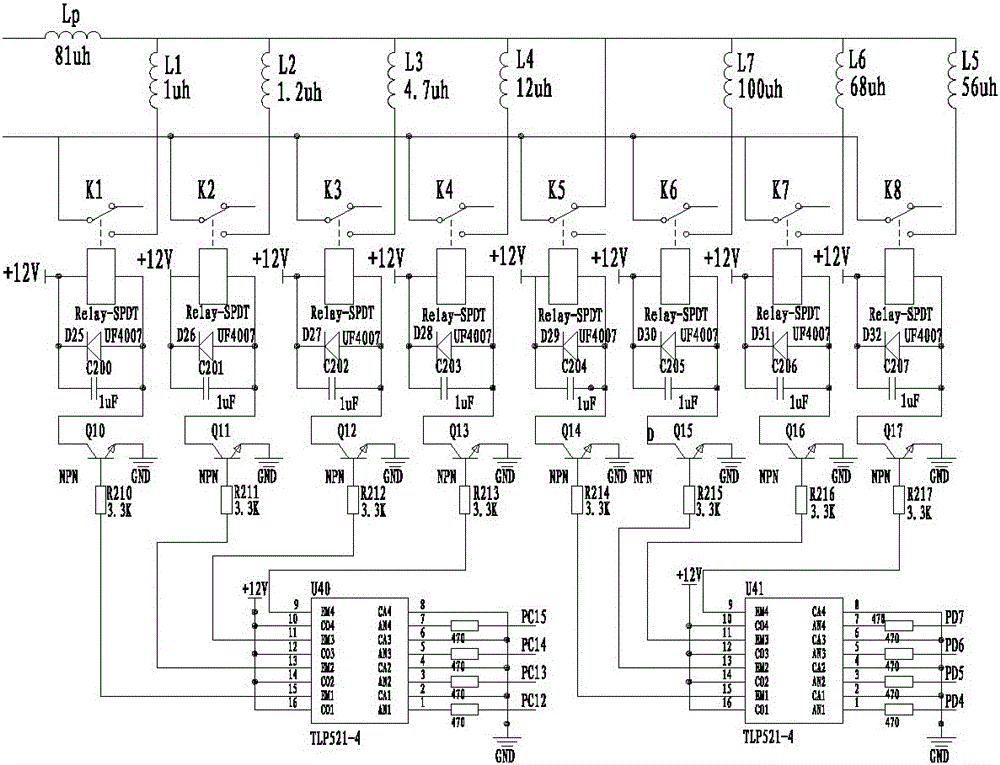

[0024] see Figure 1 to Figure 3 , an ultrasonic circuit driver with automatic impedance matching provided by the present embodiment, which includes a high-speed single-chip microcomputer module connected to each other, a DDS signal generation module, a power amplification module, an impedance dynamic matching module, a signal acquisition and control module and a protection circuit module; wherein The high-speed single-chip microcomputer module is a digital single-chip microcomputer with more than 32 bits, such as ARM and DSP microprocessors. The DDS signal generating module utilizes DDS frequency synthesis technology to generate a sine wave signal in a certain frequency range; the power amplification module adopts a full-bridge circuit composed of IGBT transistors; the impedance dynamic matching is to utilize a series of inductance, according to the circuit The current and phase feedback signals are automatically switched to the required optimal inductance; the signal acquisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com