A pipeline connector used in smart cars

A smart car and connector technology, applied in the direction of pipe joints, pipes/pipe joints/pipe fittings, pipe components, etc., can solve the problems of complex structure and inconvenient installation of self-locking devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

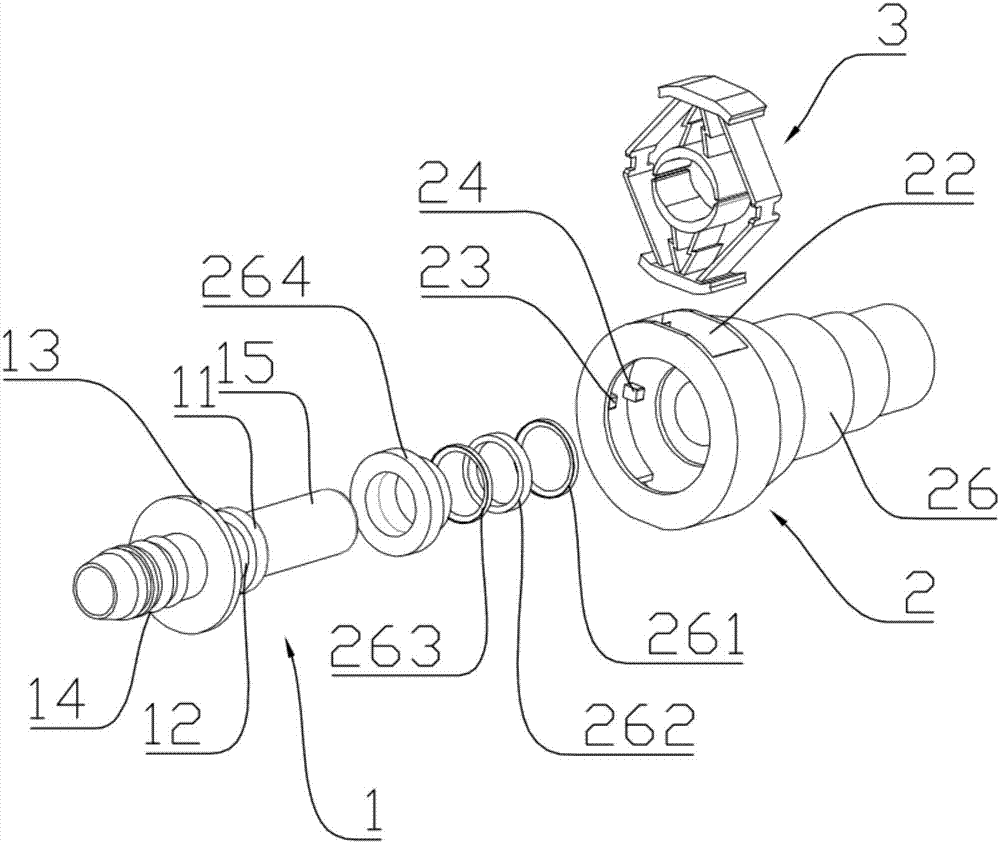

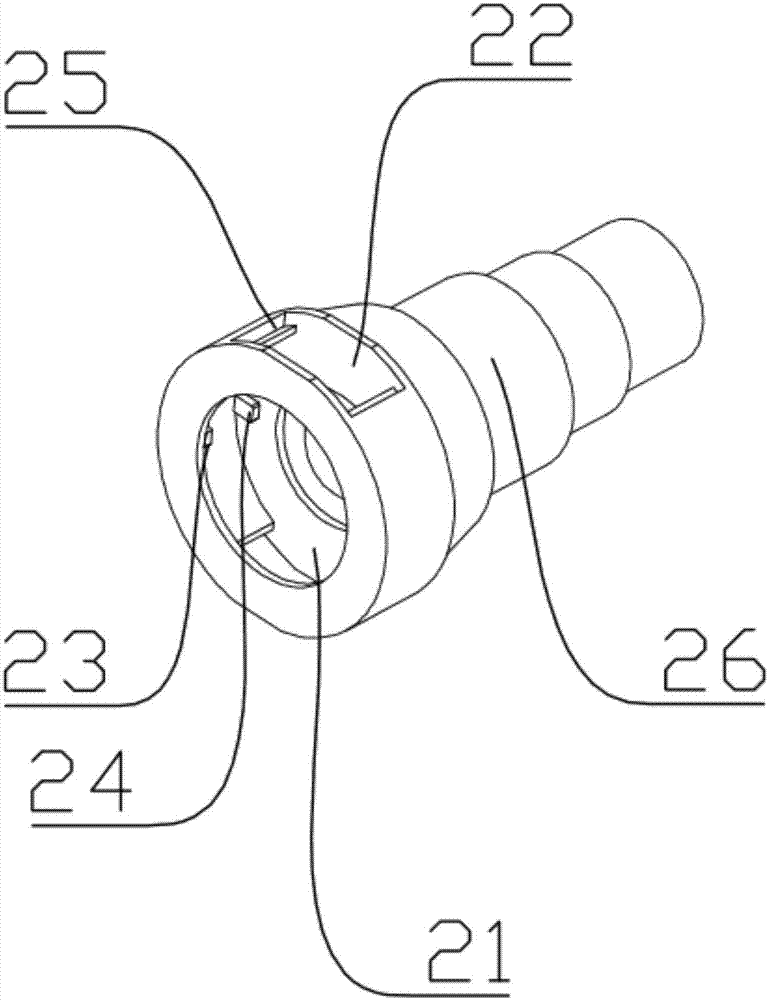

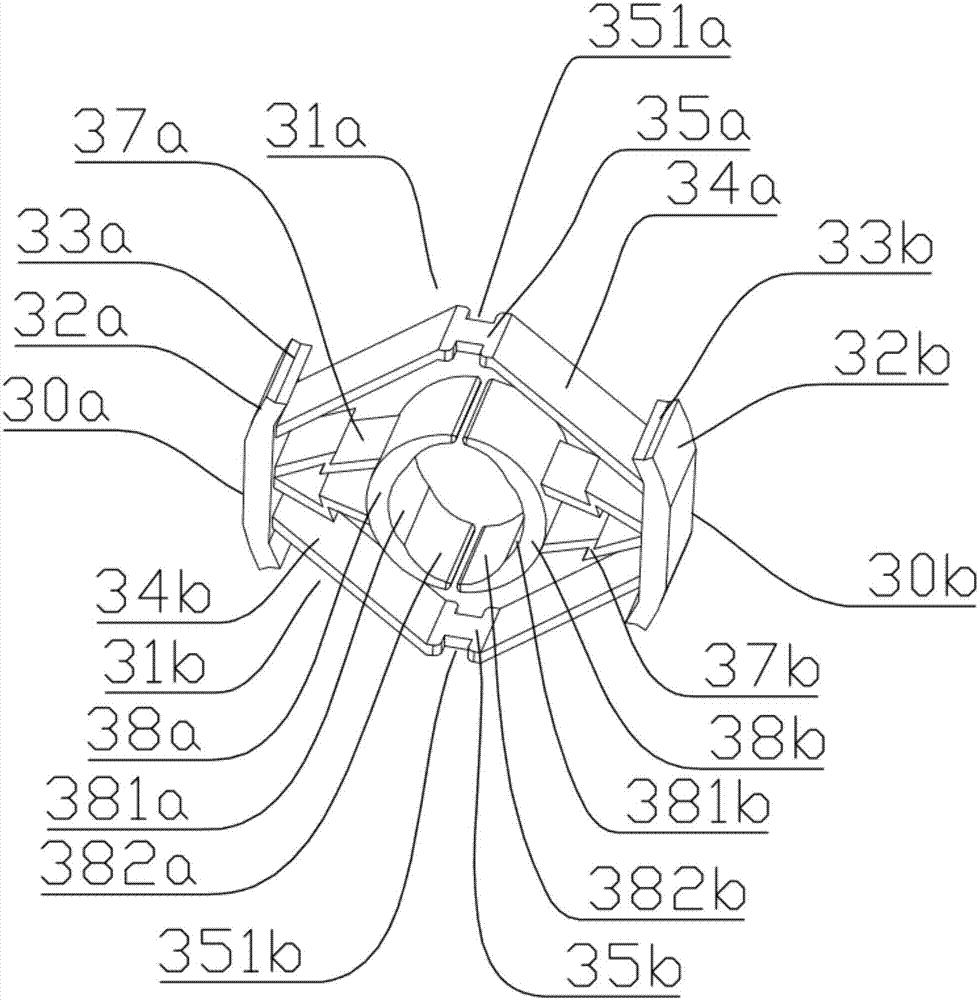

[0030] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings of the description:

[0031] Such as Figure 1-7 As shown, the present invention proposes a specific embodiment of a pipeline connector applied to a smart car. Specifically: as figure 1 , Figure 4 and Figure 6 As shown, a pipeline connector applied to smart cars in the present invention includes a male connector 1 and a female connector 2, and the male connector 1 is fixedly connected to the female connector 2 through an elastic locking member 3; the male connector 1 It is a hollow conduit, and the male joint 1 is sequentially connected by a male connecting pipe 15, a first annular protrusion 11, a second annular protrusion 13 and a first hose connection part 14; wherein: the second annular protrusion The outer diameter of 13 is larger than the outer diameter of the first annular protrusion 11 . Between the first annular protrusion 11 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com