A kind of white board powder coating and preparation method thereof

A technology of powder coating and coating method, applied in the field of chemical materials, can solve the problems of short service life, leaving traces, dust pollution, etc., and achieve the effect of enhancing cleaning resistance, good leveling, and increasing aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

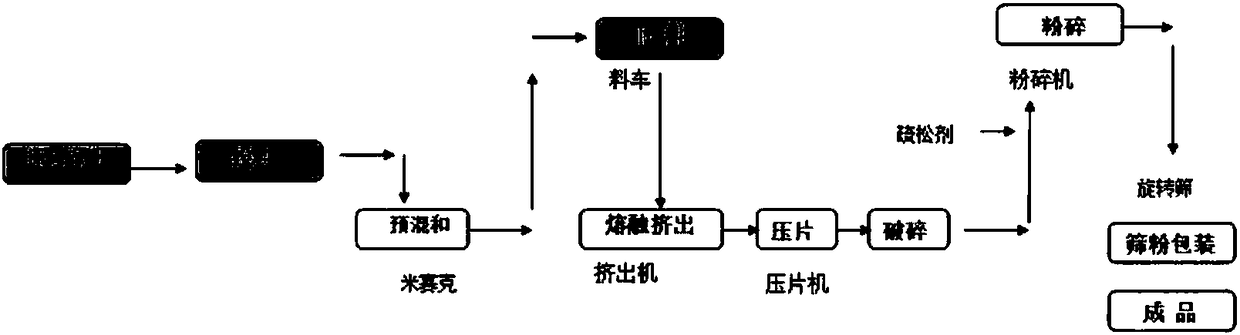

Method used

Image

Examples

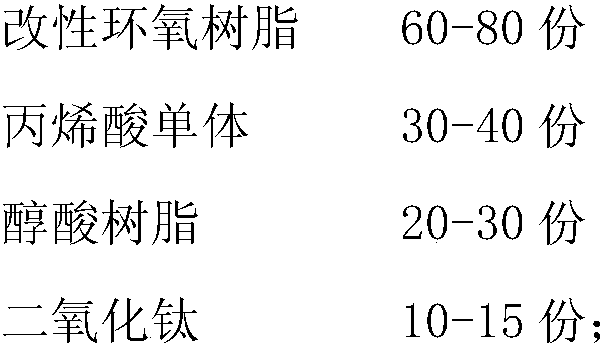

Embodiment 1

[0018] The whiteboard powder coating provided by the invention is used to coat the surface of stainless steel, wherein the formula is: 60 parts of modified epoxy resin, 30 parts of acrylic monomer, 20 parts of alkyd resin, and 10 parts of titanium dioxide. The preparation method is as follows: Weigh each raw material according to the proportion, put it in the mixing tank, mix thoroughly, melt it at 80°C and enter it into a single-screw extruder for extrusion; the extruded material is tabletted, cooled, crushed, and sieved to select particles The powder with a diameter of 10-20 μm is coated on the treated substrate by high-voltage electrostatic method, the curing temperature is 160 ℃, the curing time is 15 minutes, and it is cured in a hot oven to make the finished product A.

Embodiment 2

[0020] The whiteboard powder coating provided by the invention is used to coat the plastic surface, wherein the formula is: 60 parts of modified epoxy resin, 40 parts of acrylic monomer, 30 parts of alkyd resin, and 20 parts of titanium dioxide. The preparation method is as follows: Weigh each raw material according to the proportion, put it in the mixing tank, mix thoroughly, melt it at 80°C and enter it into a single-screw extruder for extrusion; the extruded material is tabletted, cooled, crushed, and sieved to select particles The powder with a diameter of 10-20 μm is coated on the treated substrate by high-voltage electrostatic method, the curing temperature is 170 ° C, the curing time is 15 minutes, and it is cured in a hot oven to make the finished product B.

Embodiment 3

[0022] The whiteboard powder coating provided by the invention is used to coat the fiberboard surface, wherein the formula is: 80 parts of modified epoxy resin, 40 parts of acrylic monomer, 30 parts of alkyd resin, and 20 parts of titanium dioxide. The preparation method is as follows: Weigh each raw material according to the proportion, put it in the mixing tank, mix thoroughly, melt it at 100°C and enter it into a single-screw extruder for extrusion; the extruded material is tabletted, cooled, crushed, and sieved to select particles The powder with a diameter of 20-30 μm is coated on the treated substrate by the fluidized bed method, the curing temperature is 190 ° C, the curing time is 5 minutes, and the infrared curing oven is used for curing to make the finished product C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com