Starch-free PVA collodion cotton and preparation method thereof

A technology of collodion and starch, which is applied in the field of functional polymer materials, can solve problems affecting product quality, environmental pollution, and water eutrophication, so as to avoid water eutrophication and environmental pollution, reduce production costs, and improve production processes. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

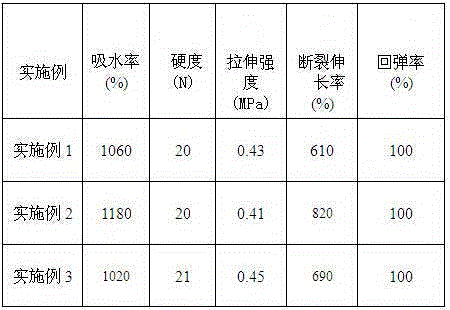

Examples

Embodiment 1

[0019] (1) Add 65g of PVA and 400g of water into the reaction vessel in turn, start stirring, heat the water bath to 80-95°C, stir for 1.5-2 hours until the PVA is completely dissolved, and obtain a PVA aqueous solution;

[0020] (2) Cool down the PVA aqueous solution prepared in step (1) to 72-78°C, add 2.2g xanthan gum, adjust the speed to 700-800r / min, stir well until the thickener is completely dissolved, add 3g dodecane Sodium sulfate, increase the speed to 1000-1200r / min, stir at high speed, make the solution foam freely to 1.7 times the original volume, control the temperature in the reaction vessel at 54-60°C, add 42g of 31% hydrochloric acid, 53g of formaldehyde with a concentration of 37.5% was stirred until the solution was evenly mixed to obtain 565.2g of viscous foam;

[0021] (3) Inject the viscous foam prepared in step (2) into the mold, then place the mold filled with the viscous foam in an oven, and cure at 60-75°C for 5-9 hours;

[0022] (4) The collodion so...

Embodiment 2

[0024] (1) Add 2.1kg of PVA and 13kg of water into the reaction vessel in turn, start stirring, heat the water bath to 80-95°C, stir for 1.5-2 hours until the PVA is completely dissolved, and obtain a PVA aqueous solution;

[0025] (2) Cool down the PVA aqueous solution prepared in step (1) to 72-78°C, add 71.5g of xanthan gum, adjust the speed to 700-800r / min, stir well until the thickener is completely dissolved, add 100g of dodecane Sodium sulfate, increase the speed to 1000-1200r / min, stir at high speed, make the solution foam freely to 1.7 times the original volume, control the temperature in the reaction vessel at 54-60°C, add 1.25kg of hydrochloric acid with a concentration of 31.5% in sequence 1.75kg of formaldehyde with a concentration of 36.5% was stirred until the solution was evenly mixed to obtain 18.17kg of viscous foam;

[0026] (3) Inject the viscous foam prepared in step (2) into the mold, then place the mold filled with the viscous foam in an oven, and cure a...

Embodiment 3

[0029] (1) Add 2.3kg of PVA and 16.5kg of water into the reaction vessel in sequence, start stirring, heat the water bath to 80-95°C, stir for 1.5-2 hours until the PVA is completely dissolved, and obtain a PVA aqueous solution;

[0030] (2) Cool down the PVA aqueous solution prepared in step (1) to 72-78°C, add 65g of xanthan gum, adjust the speed to 700-800r / min, stir well until the thickener is completely dissolved, add 90g of dodecyl Sodium sulfate, increase the speed to 1000-1200r / min, stir at high speed, make the solution foam freely to 1.7 times the original volume, control the temperature in the reaction vessel at 54-60°C, add 1.1kg of 31.5% hydrochloric acid, 1.8kg of formaldehyde with a concentration of 37.5% was stirred until the solution was evenly mixed to obtain 21.86kg of viscous foam;

[0031] (3) Inject the viscous foam prepared in step (2) into the mold, then place the mold filled with the viscous foam in an oven, and cure at 60-75°C for 5-9 hours;

[0032] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com