A kind of multiple chemical cross-linking reinforced cellulose airgel and its preparation method

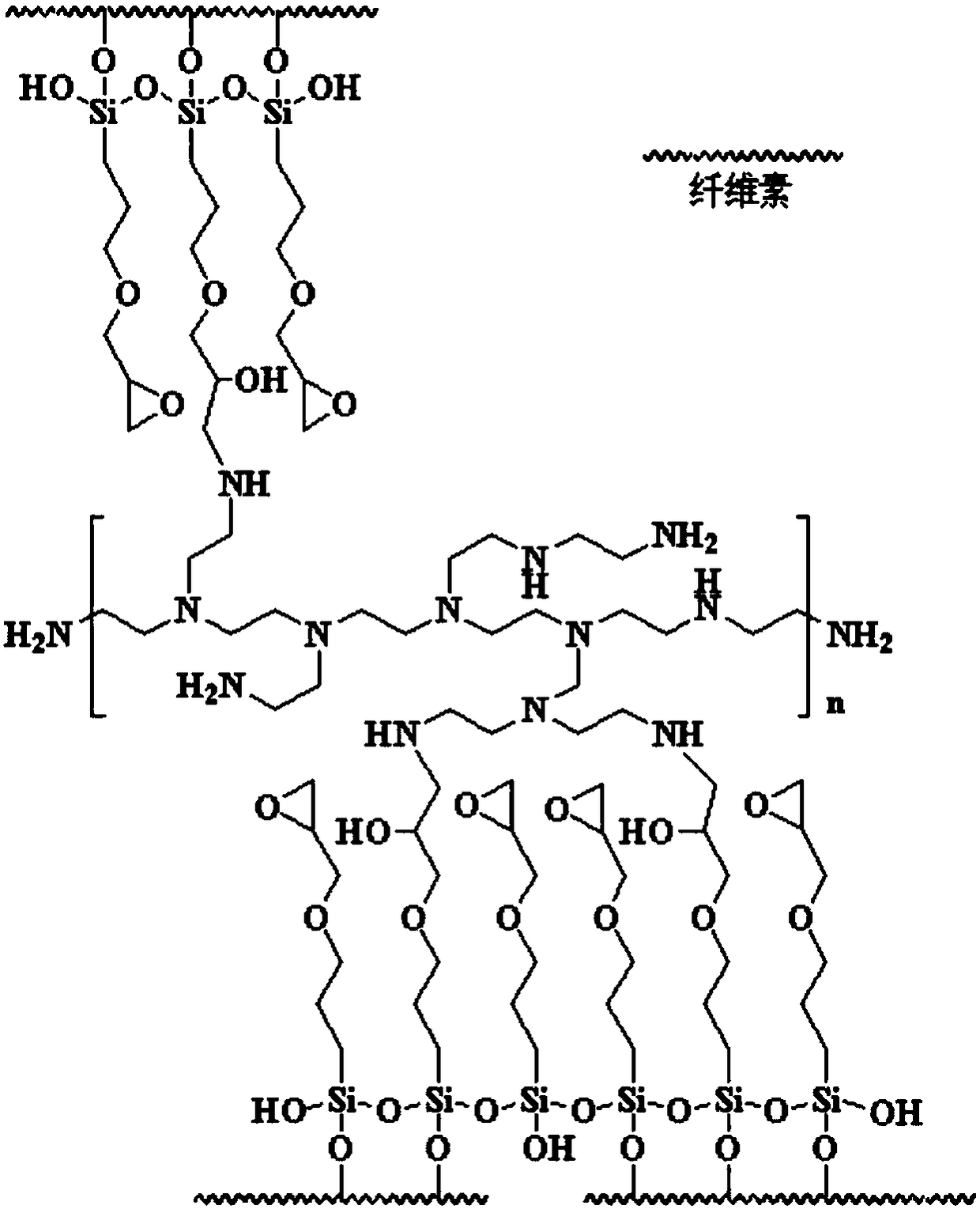

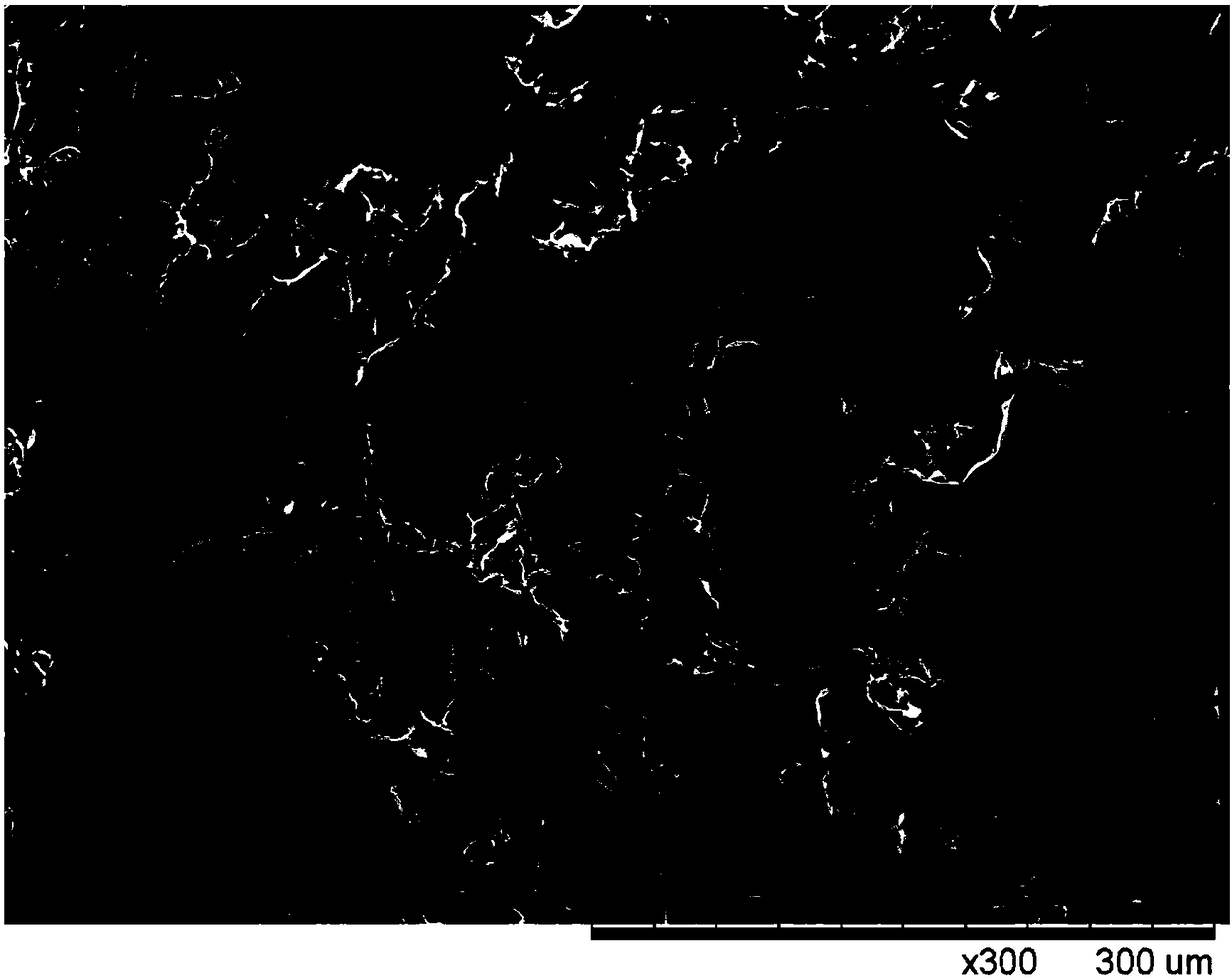

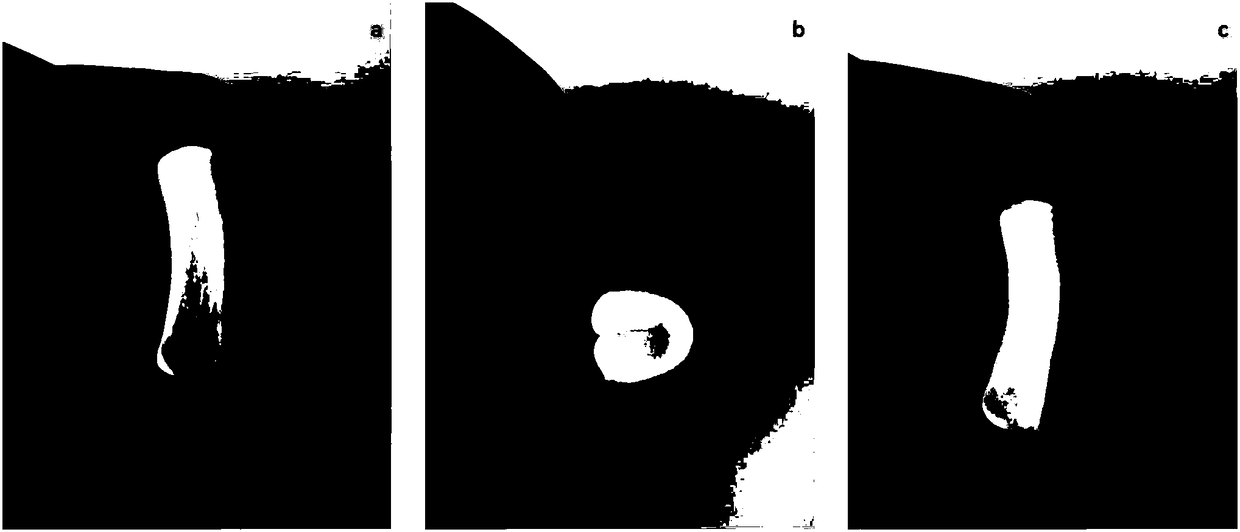

A technology of cellulose airgel and chemical crosslinking, which is applied in the field of multiple chemical crosslinking reinforced cellulose airgel and its preparation, and can solve the problems of complex cellulose modification process, poor biocompatibility, and long production cycle , to achieve a uniform and stable porous structure, increase the connection density, and enhance the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 10 g of wood pulp cellulose micron wire suspension with a mass fraction of 1.1 wt%, add silane coupling agent KH-560 into the cellulose micron wire suspension, and hydrolyze with magnetic stirring for 2 h at room temperature and neutral conditions, The methoxy groups on the silane coupling agent KH-560 are fully hydrolyzed into silicon hydroxyl groups to obtain a mixed suspension; wherein the mass ratio of cellulose micron wires to silane coupling agent KH-560 is 1:0.5.

[0031] (2) Prepare an aqueous solution of branched polyethyleneimine (molecular weight: 600) with a concentration of 15 wt % with deionized water. At room temperature, add the branched polyethyleneimine aqueous solution to the mixed suspension obtained in (1), and at room temperature, stir magnetically for 30 minutes to make the epoxy group of the silane coupling agent KH-560 and the branched polyethyleneimine The amino group of the cellulose fully reacts and cross-links; wherein, the mass ra...

Embodiment 2

[0034] (1) Weigh 10 g of wood pulp cellulose micron wire suspension with a mass fraction of 1.1 wt%, add silane coupling agent KH-560 into the cellulose micron wire suspension, adjust the pH value to 8 at room temperature, and magnetically stir Hydrolyze for 2 hours to fully hydrolyze the methoxy groups on the silane coupling agent KH-560 into silicon hydroxyl groups to obtain a mixed suspension; wherein the mass ratio of cellulose micron wires to silane coupling agent KH-560 is 1:1.

[0035] (2) Prepare an aqueous solution of branched polyethyleneimine (molecular weight: 1000) with a concentration of 15 wt % with deionized water. At room temperature, add the branched polyethyleneimine aqueous solution to the mixed suspension obtained in (1), and at room temperature, stir magnetically for 30 minutes to make the epoxy group of the silane coupling agent KH-560 and the branched polyethyleneimine The amino group of the group fully reacts and cross-links; wherein, the mass ratio of...

Embodiment 3

[0039] (1) Weigh 10 g of wood pulp cellulose micron wire suspension with a mass fraction of 1.1 wt%, add silane coupling agent KH-560 into the cellulose micron wire suspension, and hydrolyze with magnetic stirring for 2 h at room temperature and neutral conditions, The methoxy groups on the silane coupling agent KH-560 are fully hydrolyzed into silicon hydroxyl groups to obtain a mixed suspension; wherein, the mass ratio of cellulose micron wires to silane coupling agent KH-560 is 1:1.

[0040] (2) Prepare an aqueous solution of branched polyethyleneimine (molecular weight: 1200) with a concentration of 25 wt % with deionized water. At room temperature, add the branched polyethyleneimine aqueous solution to the mixed suspension obtained in (1), and at room temperature, stir magnetically for 30 minutes to make the epoxy group of the silane coupling agent KH-560 and the branched polyethyleneimine The amino group of the group fully reacts and cross-links; wherein, the mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com