Long-life permeable concrete and production method thereof

A permeable concrete and life-span technology, applied in the field of concrete, can solve the problems of poor compressive strength and water permeability and air permeability, and achieve high freeze-thaw resistance, high bearing capacity, and the effect of maintaining ecological balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

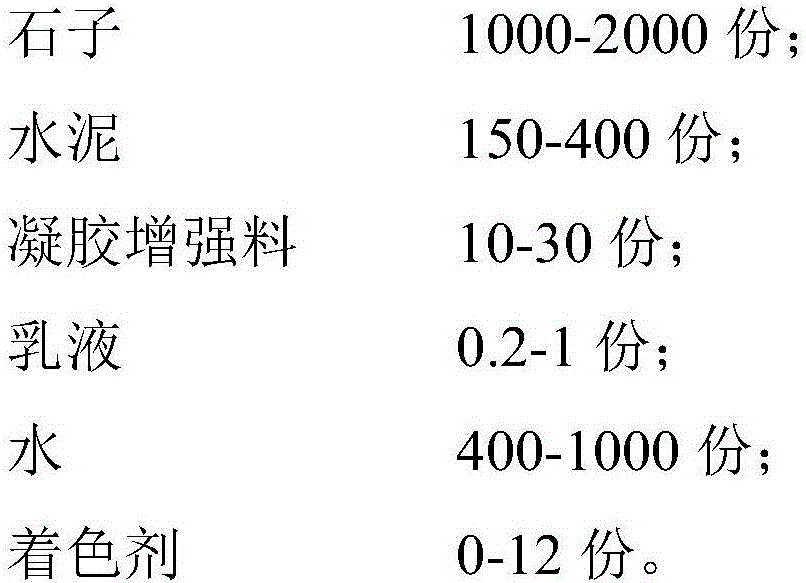

Method used

Image

Examples

Embodiment 1

[0054] Preparation method of gel reinforcement:

[0055] Weighing: 100 kg of cement; 250 kg of silica; 50 kg of polyvinyl alcohol; 25 kg of redispersible latex powder (VAE); 10 kg of brightener; 10 kg of water reducing agent; 15 kg of lignin fiber. The gel reinforcing material of the present invention can be obtained by stirring and mixing the above raw materials evenly.

[0056] The water reducer is the model PC-1030 defoaming polycarboxylate water reducer produced by Suzhou Xingbang Chemical Building Materials Co., Ltd.

[0057] The brightener is bright powder produced by Suzhou Xingbang Chemical Building Materials Co., Ltd.

[0058] Preparation method of high service life permeable concrete:

[0059] Add 0.4 kg of emulsion (i.e. SD-818 emulsion for real stone paint) into 3.6 kg of water and stir to mix evenly to obtain an emulsified reactant;

[0060] Add 1600 kg of basalt crushed stones, 320 kg of 42.5 gray cement, 15 kg of the gel reinforcement prepared above, 4 kg of ...

Embodiment 2

[0064] Basically the same as Example 1, the difference is: the water reducer is composed of 2,7-dihydroxynaphthalene-3,6-sodium disulfonate and 2,6-di-tert-butylnaphthalene sodium sulfonate according to the mass ratio of 1: 1 blended.

[0065] The brightener is oleic acid diethanolamine salt.

Embodiment 3

[0067] It is basically the same as Example 1, the only difference is that the water reducer is mixed with sodium tris(1-methylethyl)naphthalenesulfonate and sodium 2,6-di-tert-butylnaphthalenesulfonate in a mass ratio of 1:1 made.

[0068] The brightener is oleic acid diethanolamine salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com