A complete three-slime recovery and treatment process

A process method and recycling technology, applied in sludge treatment, water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, etc., can solve the problems of high capital, damage, low utilization rate of three sludges, etc. , to achieve the effect of accelerating solid sedimentation, improving treatment efficiency and reducing treatment difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

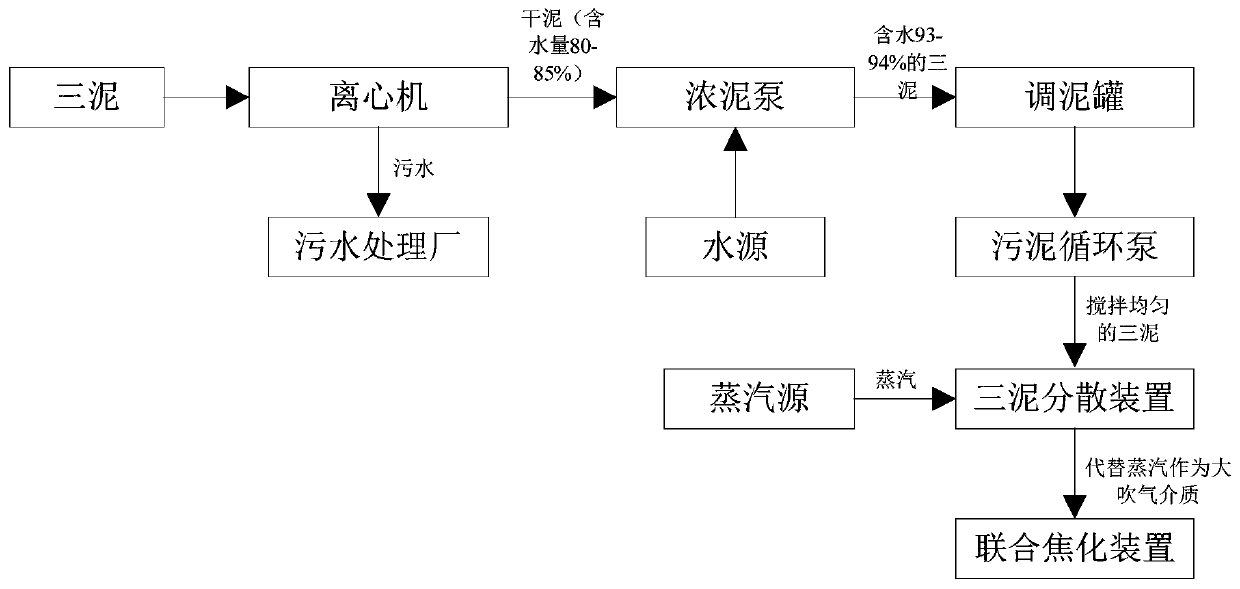

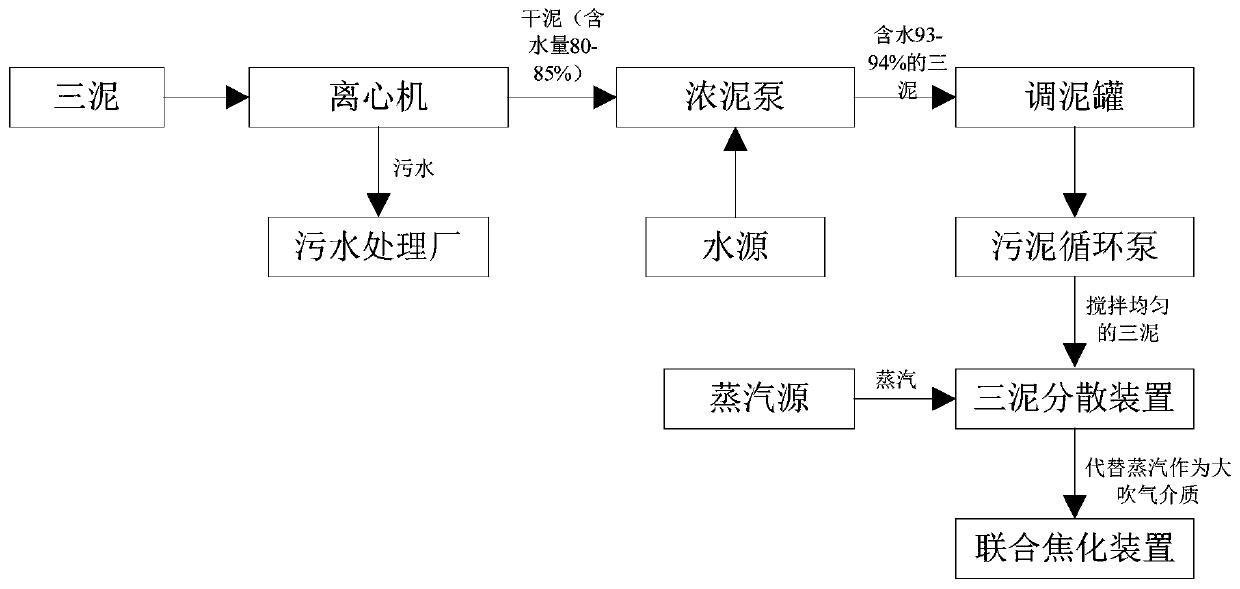

[0026] Such as figure 1 As shown, the equipment required for a complete three-sludge recovery and treatment process includes a centrifuge, a thick sludge pump, a sludge adjustment tank, a sludge circulation pump, a three-sludge dispersion device, and a combined coking device.

[0027] The method specifically includes the following steps:

[0028] a) Centrifugal operation

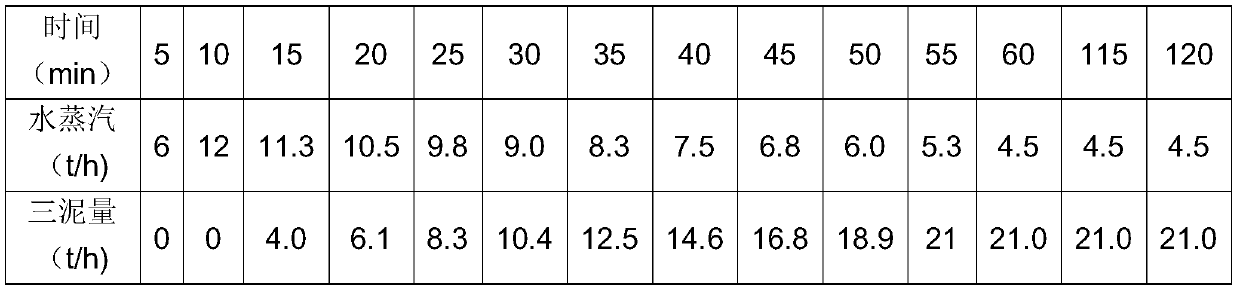

[0029] The three mud and polyacrylamide are added into the centrifuge for centrifugation, the obtained dry mud is transported to the thick mud pump, and the obtained sewage is transported to the sewage treatment plant for recovery and treatment. Wherein, the rotating speed of the centrifuge is 2500-3000rpm and the differential speed is 5-10rpm when performing three-slime centrifugal operation. In order to make the solid-liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com